Temsan Industrial Fan Solutions

T emsan brings its long-standing expertise in textile air conditioning and filtration systems into industrial fan design, offering a comprehensive portfolio for air transfer, dust conveying, and material transportation. From high-efficiency plug fans to heavy-duty axial, dust conveying, and material conveying fans, each series is engineered for durability, performance, and seamless integration into your process.

WHY TEMSAN FANS?

OUR FANS

For performance curves and engineering support, please contact our technical team.

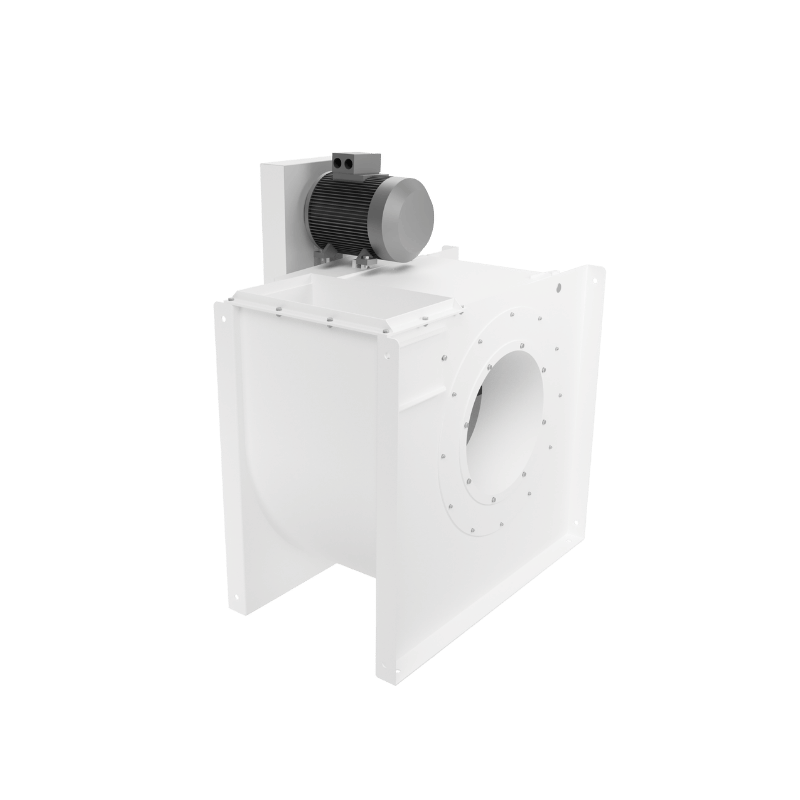

- T-MAX Plug Fan Series

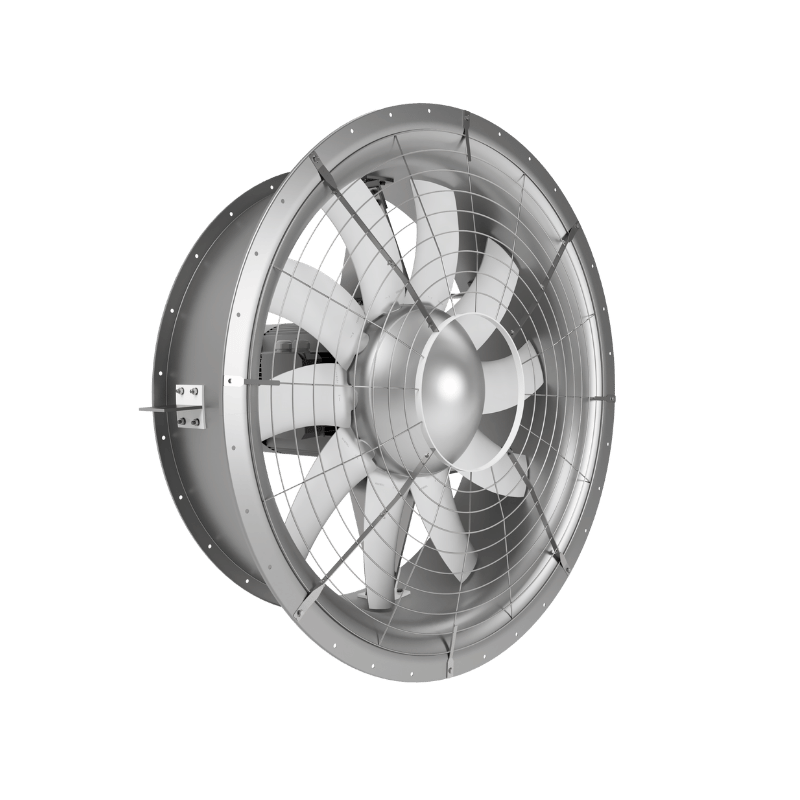

- Axial Fan Series

- Dust Conveying Fan Series

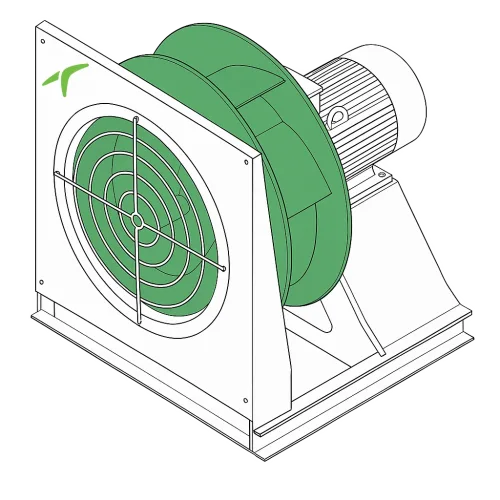

- Material Conveying Fan [Direct Drive]

- Material Conveying Fan – TV (Belt-Driven)

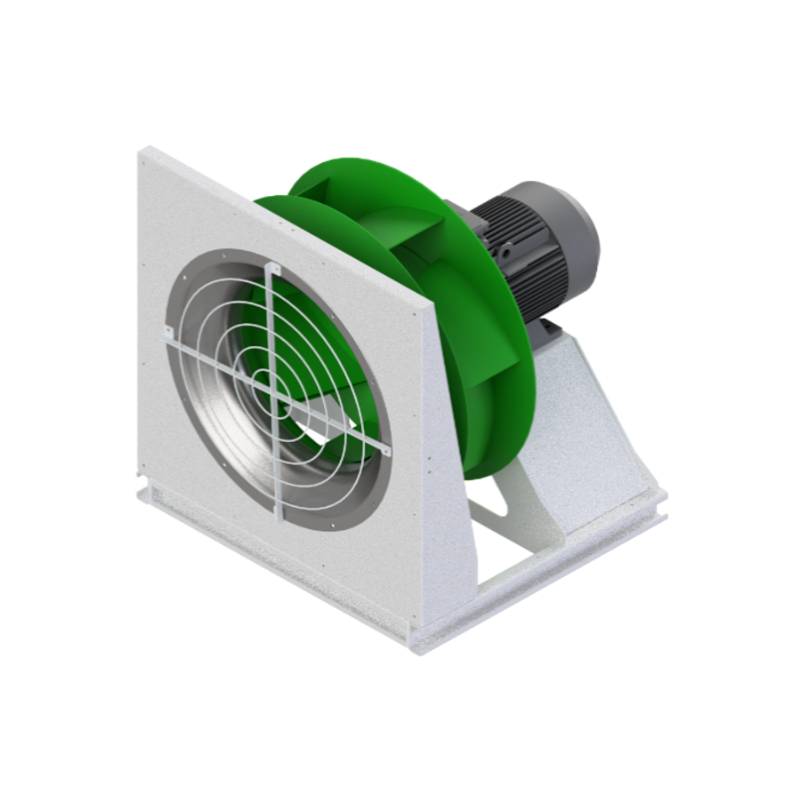

The Temsan T-MAX Plug Fan Series is designed for high-efficiency air movement in industrial HVAC systems, featuring backward-curved airfoil blades and direct-drive motors for maximum performance.

Applications

- Textile air conditioning units

- Industrial HVAC systems

- Fresh air and recirculation units

- General industrial air transfer

Technical Range

- Airflow: 5,000 – 74,000 m³/h

- Static Pressure: 100 – 2,300 Pa

- Speed: 420 – 1,470 rpm

- Power: 7.5 – 37 kW

Design Highlights

- Backward-curved airfoil blades

- Steel housing with powder coating

- High-efficiency IE3/IE4 motors

- Fully inverter-compatible

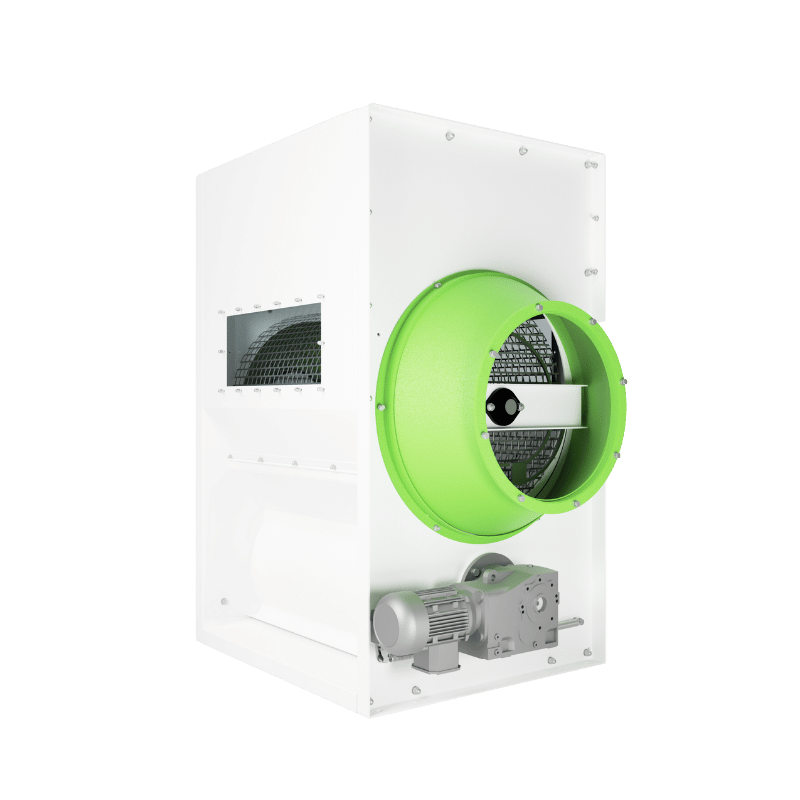

Temsan Axial Fans are engineered for large airflow volumes with low-to-medium static pressure, using cast-aluminum airfoil blades.

Applications

- Textile fresh air and exhaust lines

- Large production halls and warehouses

- HVAC air transfer systems

- Cooling and ventilation zones

Technical Range

- Airflow: 14,000 – 210,000 m³/h

- Pressure: up to 700 Pa

- Speed: up to 1,000 rpm

- Power: 11 – 45 kW

Design Highlights

- Adjustable-pitch airfoil blades

- Corrosion-resistant steel casing

- High-efficiency IE3/IE4 motors

- Low-noise aerodynamic design

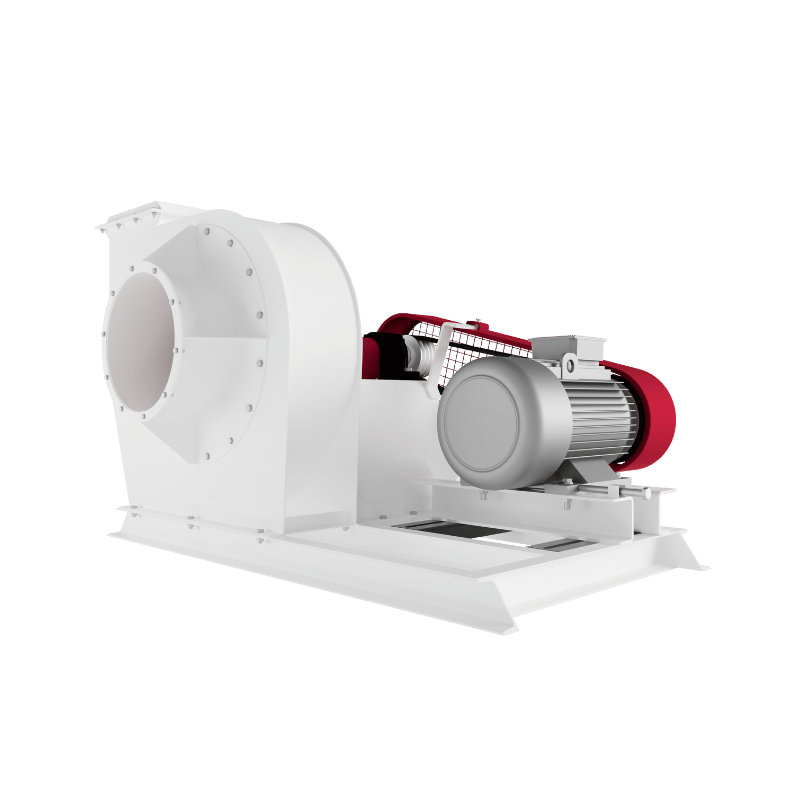

Temsan Dust Conveying Fans are engineered for high-pressure applications such as dust collection systems and cyclones, built to handle abrasive dust loads.

Applications

- Dust collection systems

- Cyclone separators

- Textile dust conveying lines

- Negative-pressure extraction systems

Technical Range

- Airflow: 800 – 2,500 m³/h

- Static Pressure: 4,500 – 7,000 Pa

- Speed: up to 3,000 rpm

- Power: 4 – 7.5 kW

Design Highlights

- Abrasion-resistant steel blades

- Reinforced housing for long life

- Powder-coated surfaces

- Modular installation options

Engineered for lightweight material and waste transportation, ensuring efficient flow and minimal maintenance due to its open blade geometry.

Applications

- Fiber and waste conveying lines

- Light material transfer systems

- Textile production waste transport

- Local material handling points

Technical Range

- Airflow: 950 – 9,250 m³/h

- Static Pressure: 1,400 – 4,300 Pa

- Speed: up to 3,000 rpm

- Power: 4 – 15 kW

Design Highlights

- Non-sparking cast-aluminum blades

- Open-straight blade geometry

- Powder-coated steel frame

- Modular design for orientation options

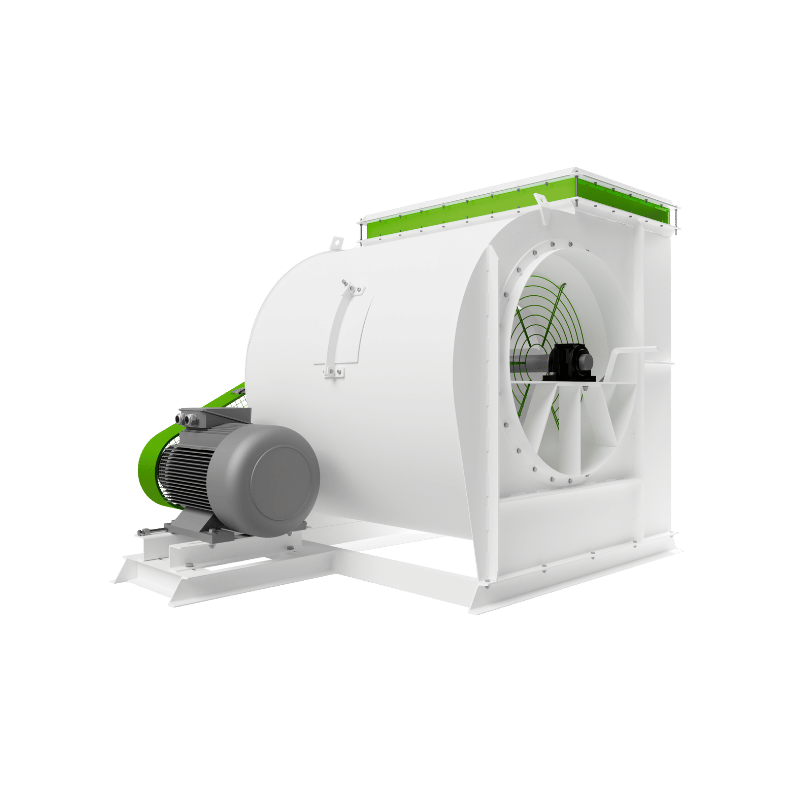

The TV Series is designed for heavy-capacity material transport, supporting long conveying distances and variable loading with belt-driven flexibility.

Applications

- Central waste conveying systems

- Woodworking dust transport lines

- Heavy textile waste movement

- High-pressure material handling

Technical Range

- Airflow: 2,150 – 20,350 m³/h

- Static Pressure: 210 – 3,850 Pa

- Speed: 955 – 2,100 rpm

- Power: 11 – 22 kW

Design Highlights

- Belt-drive system for speed flexibility

- Cast-aluminum or steel blade options

- Straight-blade design for continuous flow

- Rigid steel base for vibration reduction

TECHNICAL COMPARISON TABLE

| Fan Series | Airflow (m³/h) | Pressure (Pa) | Speed (rpm) | Power (kW) | Motor Class |

|---|---|---|---|---|---|

| T-MAX Plug Fans | 5,000 – 74,000 | 100 – 2,300 | 420 – 1,470 | 5.5 – 30 | IE3 / IE4 |

| Axial Fans | 14,000 – 210,000 | up to 700 | up to 1,000 | 11 – 45 | IE3 / IE4 |

| Dust Conveying Fans | 800 – 2,500 | 4,500 – 7,000 | up to 3,000 | 4 – 7.5 | IE3 / IE4 |

| Material Conveying (Direct Drive) | 950 – 9,250 | 1,400 – 4,300 | up to 3,000 | 4 – 15 | IE3 / IE4 |

| Material Conveying – TV (Belt) | 2,150 – 20,350 | 210 – 3,850 | 955 – 2,100 | 11 – 22 | IE3 / IE4 |

** For performance curves and fan selection support, contact our engineering team.