NONWOVEN APPLICATIONS

Nonwoven production environments require precise airflow, stable temperature and humidity, and exceptional dust control. From carding to bonding, Temsan’s air conditioning and filtration systems support consistent web quality, minimize maintenance, and improve plant cleanliness — while maximizing energy efficiency and uptime.

Optimizing Air Conditioning for NONWOVEN Efficiency

Maintaining proper humidity, temperature, air quality, and energy balance is essential in NONWOVEN halls. Below, you’ll find how each of these factors contributes to better fabric quality, lower costs, and higher machine efficiency.

Maintaining the right humidity prevents static buildup and fiber clinging during carding, web laying, and bonding.

- Reduces Electrostatic Discharge on Synthetic Fibers

- Prevents Fiber Clumping and Uncontrolled Web Movement

- Supports Consistent Fiber Loft and Density

- Minimizes Needle Breakage in Needlepunch Applications

- Protects Sensor Accuracy in Card & Crosslapper Zones

Result: Smooth fiber handling, less static disruption, and stable web structure.

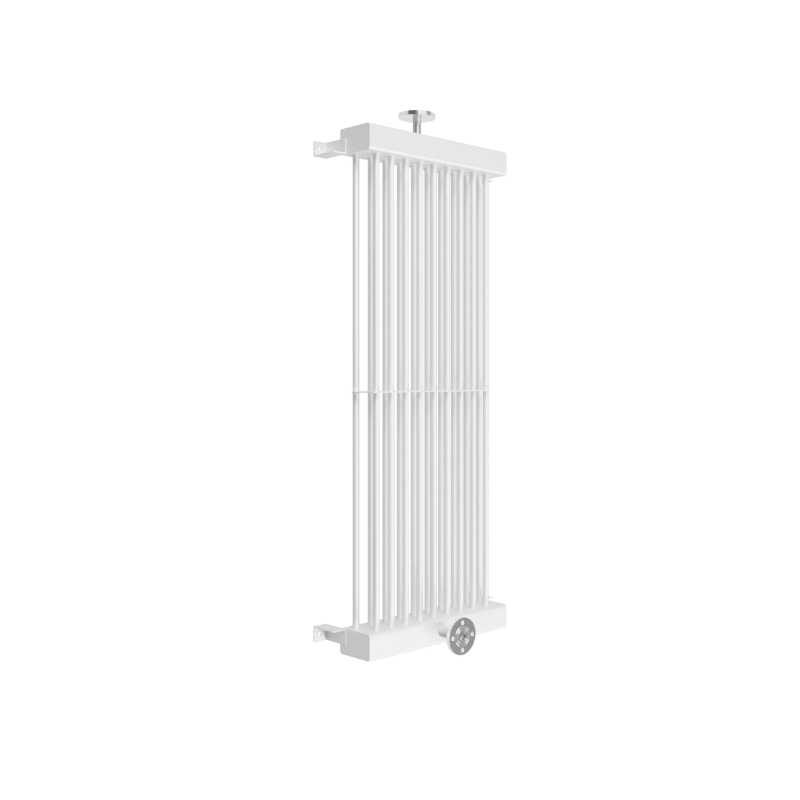

Stable temperature control improves bonding uniformity, energy efficiency, and production speed.

- Maintains Web Flatness and Shrink Control in Thermobonding

- Prevents Heat Zones from Affecting Overall Hall Conditions

- Supports Stable RH at High Airflow Volumes

- Improves Operator Safety and Equipment Cooling

Result: Better bonding consistency, longer equipment life, and improved comfort.

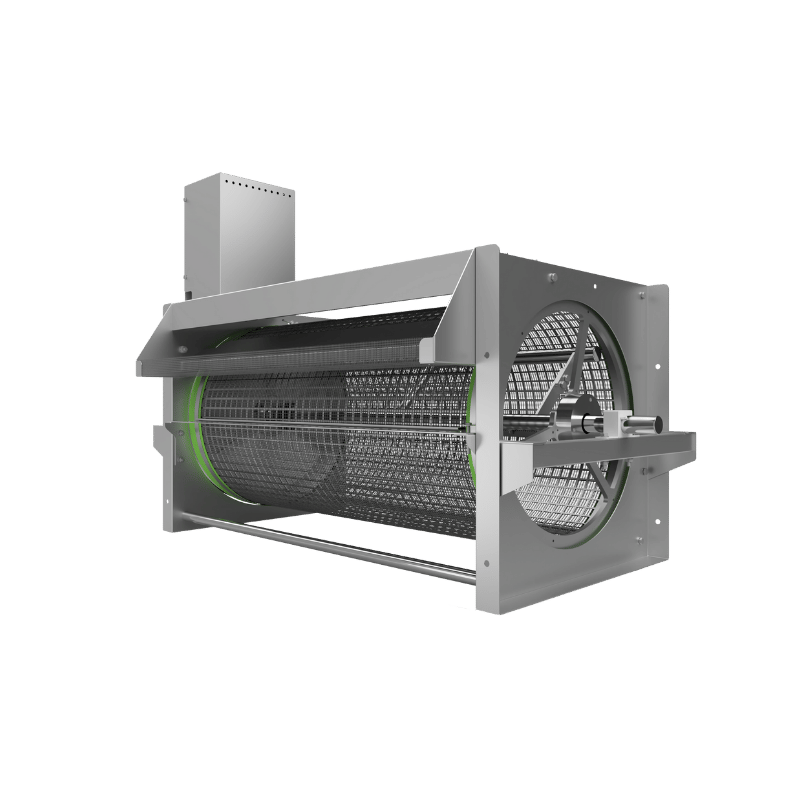

Nonwoven operations produce continuous dust and microfibers — demanding high-efficiency filtration and airflow control.

- Captures Fine Dust from Carding, Cutting, and Edge Trimming

- Protects Machinery from Fiber Buildup

- Reduces Dust Accumulation on Electrical Panels and Ducts

- Improves Cleanroom Compliance for Hygiene Products

Result: A cleaner production line, fewer breakdowns, and consistent product quality.

Temsan’s energy-saving systems reduce operational costs even with high air volume requirements.

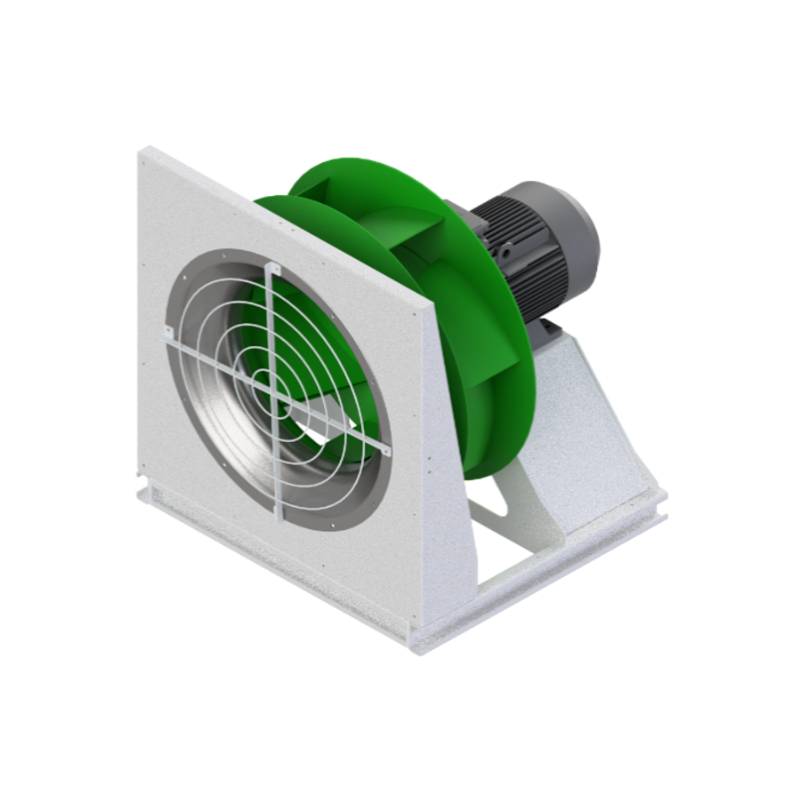

- Inverter Axial Fans Adjust to Load and Time-of-Day

- Low-Pressure Filter Layout Reduces Air Resistance

- Zone-Specific Control via Aircon Automation

- Night Mode Settings and Production Scheduling

Result: Up to 30% energy savings while maintaining process stability and air quality.

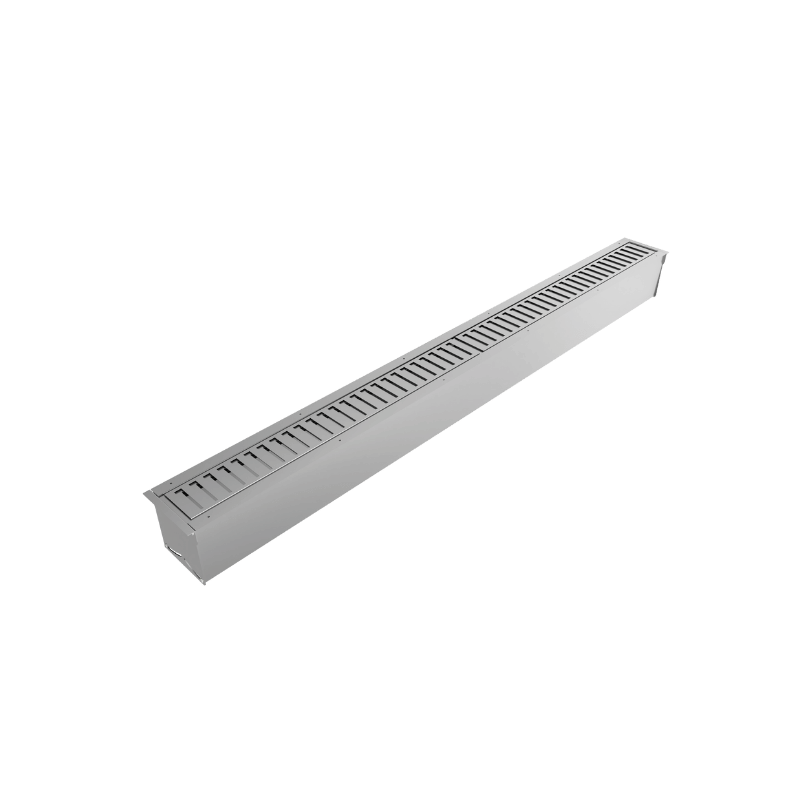

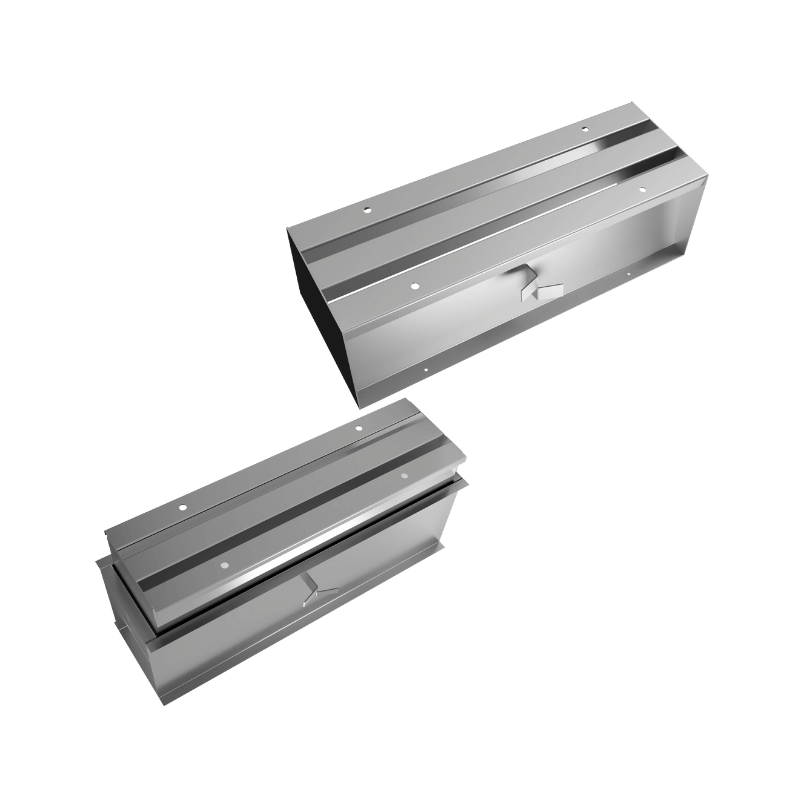

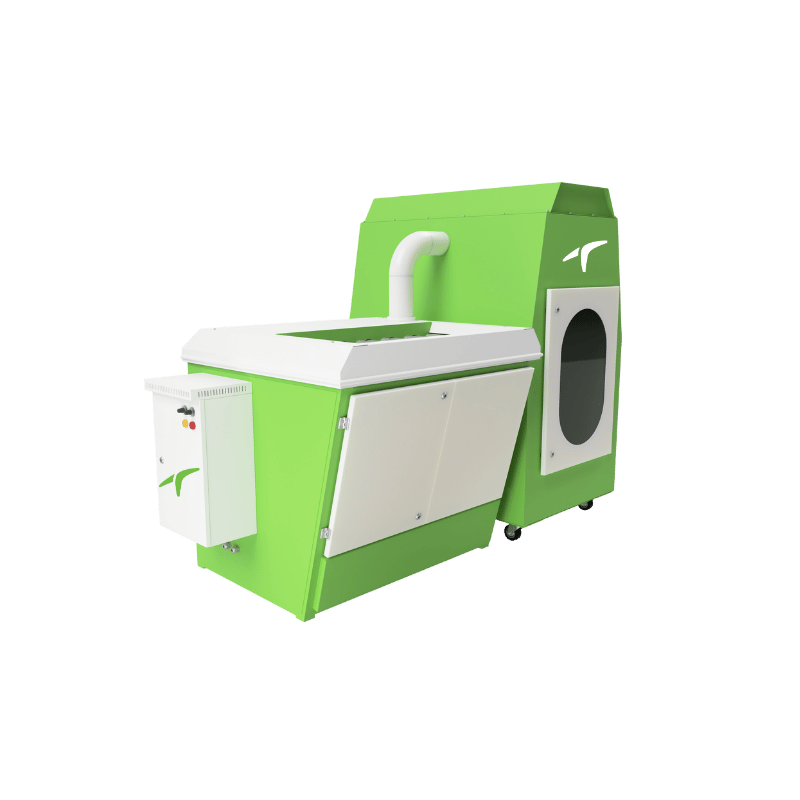

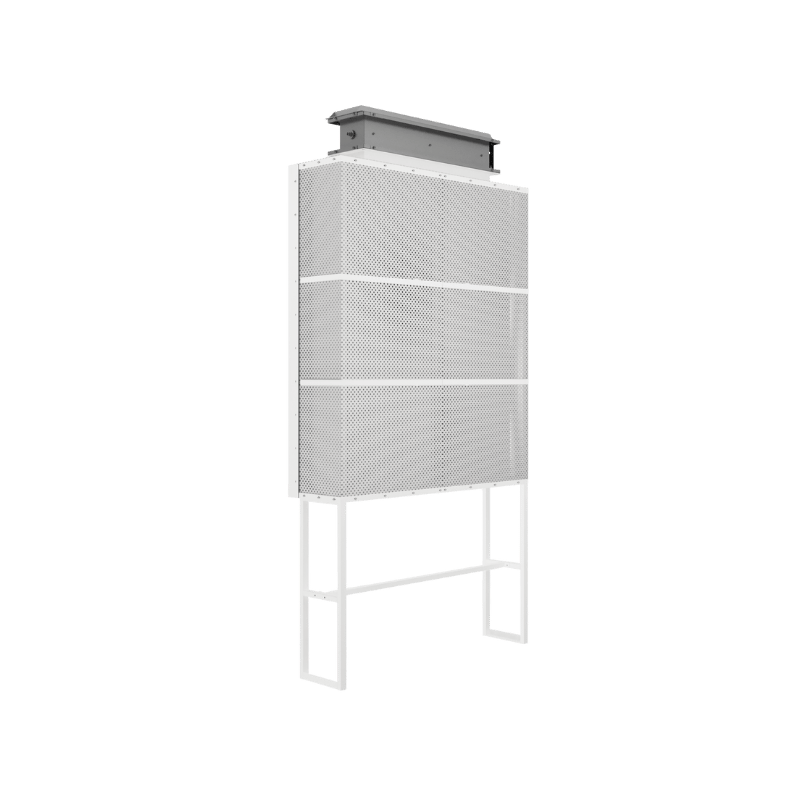

DUCT TYPE DIFFUSER

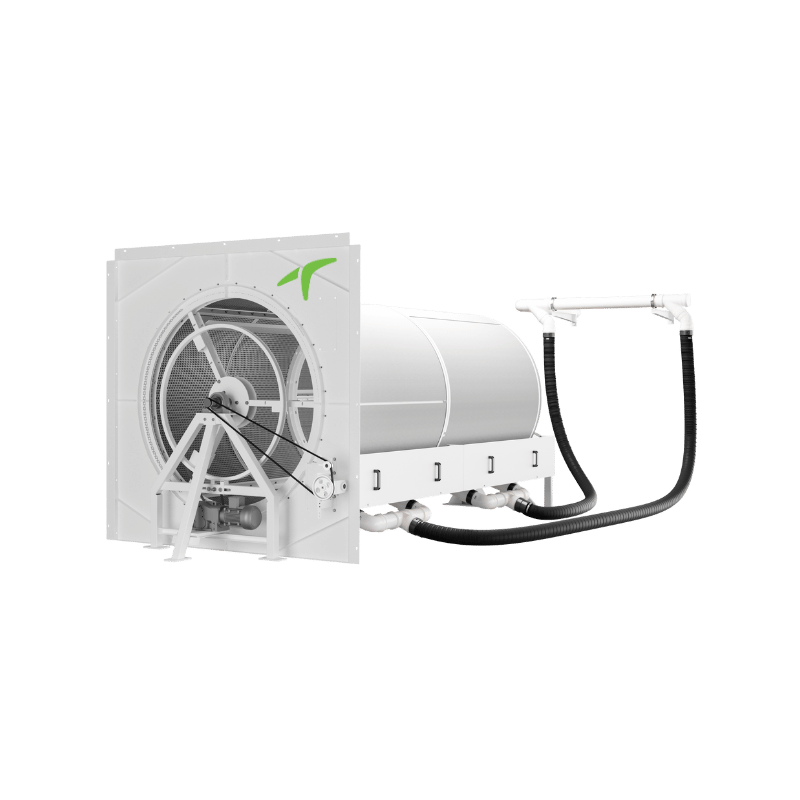

Key Components of Temsan Air Conditioning and Filtration Systems

Filtration Components:

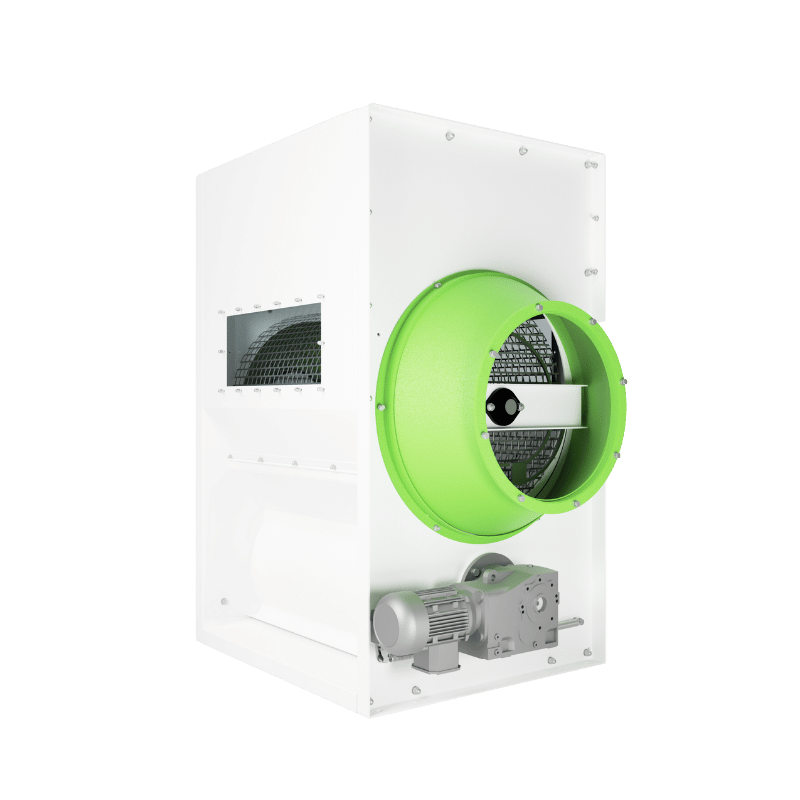

Air Conditioning Components:

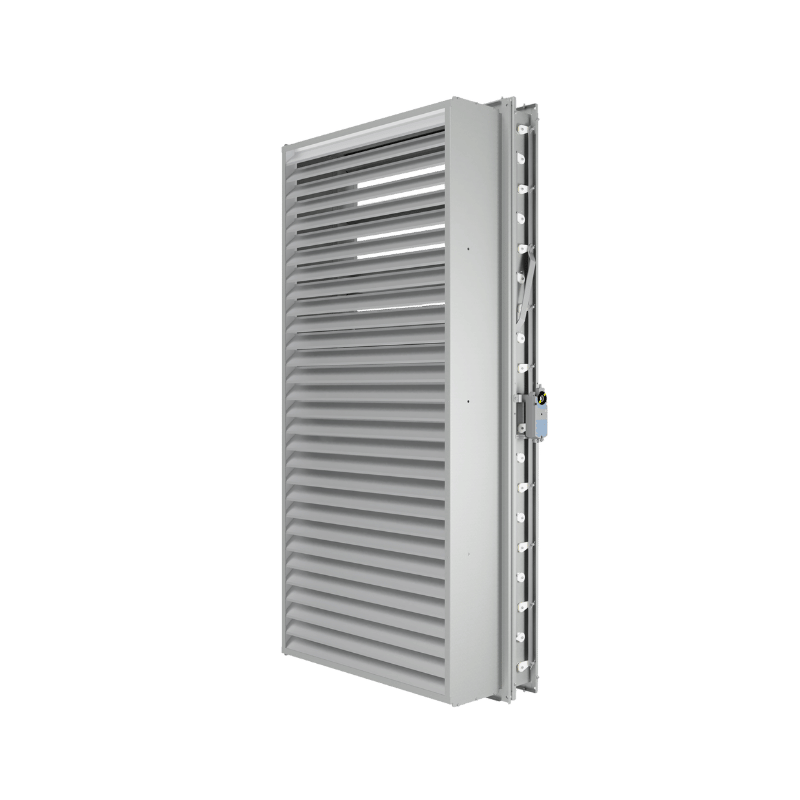

Duct Design and Components

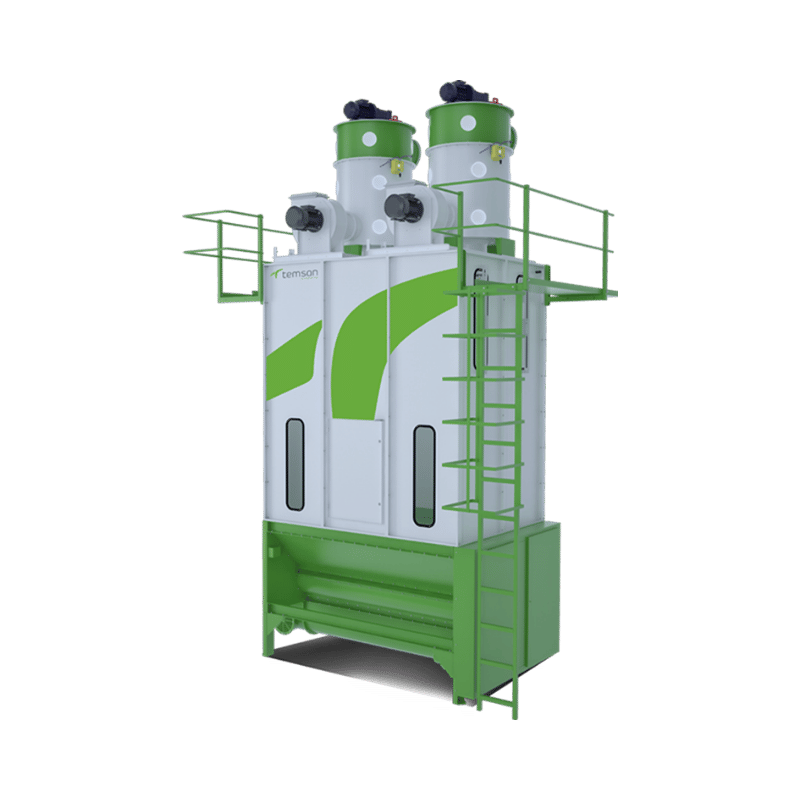

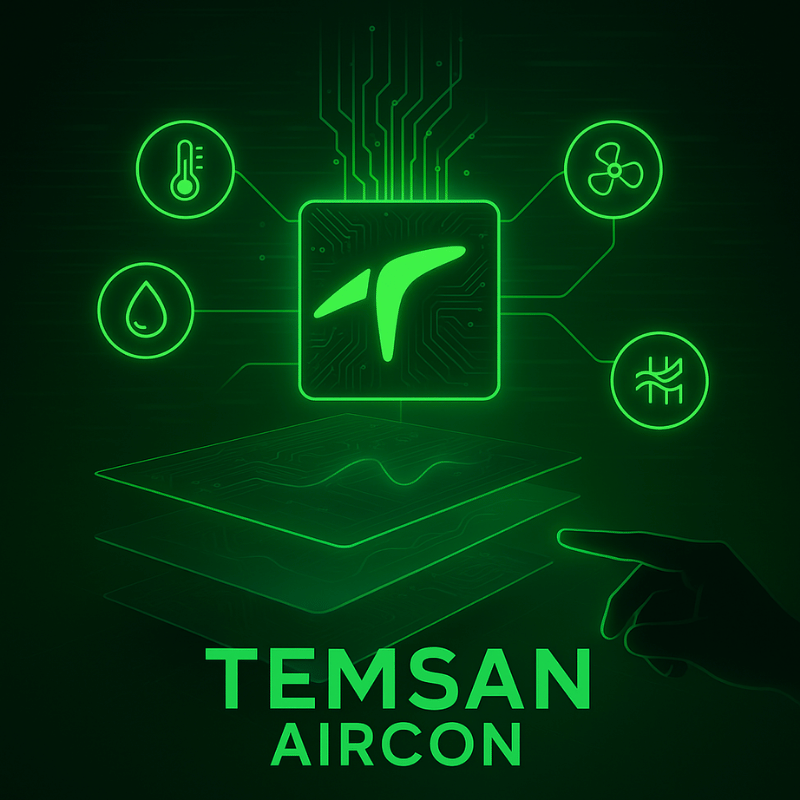

TEMSAN AIRCON

- Real-time monitoring of temperature, humidity, and airflow

- Inverter-controlled axial fans for energy-efficient air delivery

- Servo dampers automatically balance fresh, exhaust, and return air

- Mobile and web-based access through Temsan Aircon platform

- Automatic and manual operation via HMI and SCADA interface

- Chiller & heating compatability with easy management

- Designed to run energy efficient to reduce your cost with higher productivity

Key Considerations in Textile A/C and Filtration Systems

High-Quality Products

Energy Efficiency