VORTEX & AIRJET APPLICATIONS

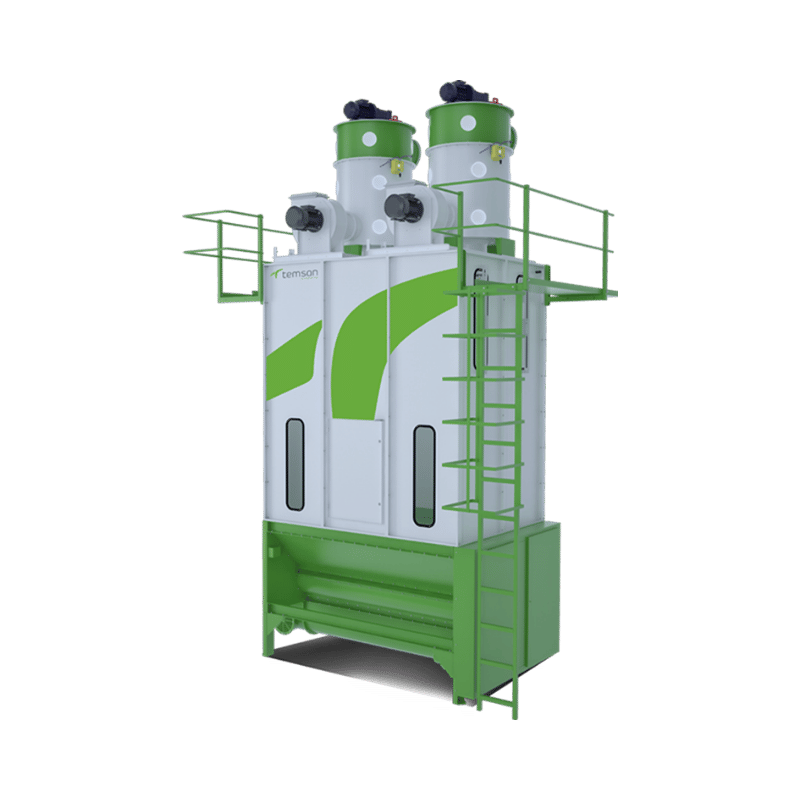

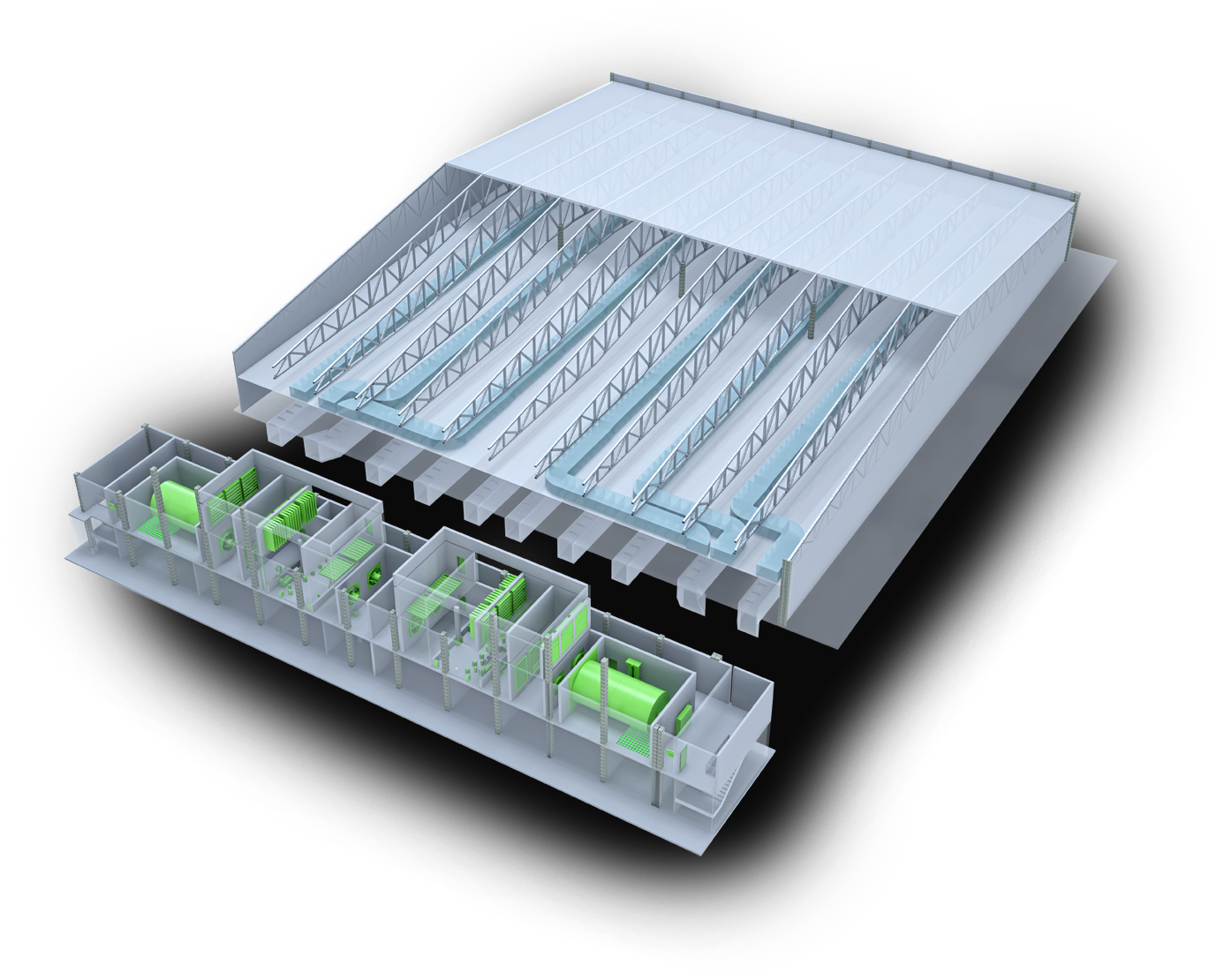

Airjet and vortex spinning technologies demand extremely stable air conditions to produce high-quality yarn at ultra-high speeds. Even minor fluctuations in temperature, humidity, or fiber fly levels can lead to imperfections. Temsan’s air conditioning and filtration systems deliver precise environmental control, energy efficiency, and production stability — supporting consistently high yarn quality with minimal downtime.

Optimizing Air Conditioning for AIR JET & VORTEX Efficiency

Maintaining precise humidity, temperature, air quality, and energy control is essential in AIRJET & VORTEX spinning lines. These advanced technologies operate at extremely high speeds, where even the slightest environmental fluctuation can impact yarn quality and process stability. Below, you’ll find how each of these factors contributes to flawless yarn formation, reduced machine maintenance, and improved production efficiency.

Maintaining stable humidity prevents fiber misalignment and clinging, which are critical for vortex and airjet technologies.

- Prevents Nozzle Blockage from Clumped or Static-Laden Fibers

- Ensures Smooth Yarn Twisting Without Tangling

- Supports Uniform Air Pressure at Jet Zones

- Reduces Hairiness and Yarn Faults

Result: Flawless yarn formation and fewer spinning stops.

Accurate temperature control helps ensure fiber flow consistency and protects sensor performance during high-speed spinning.

- Minimizes Yarn Tension Variations Caused by Air Density Shifts

- Prevents Thermally Induced Static Build-Up

- Improves Electronic System Stability (Cameras, Feeders)

- Reduces Heat Buildup Around High-Speed Nozzles

Result: Continuous, fault-free yarn delivery and better sensor accuracy.

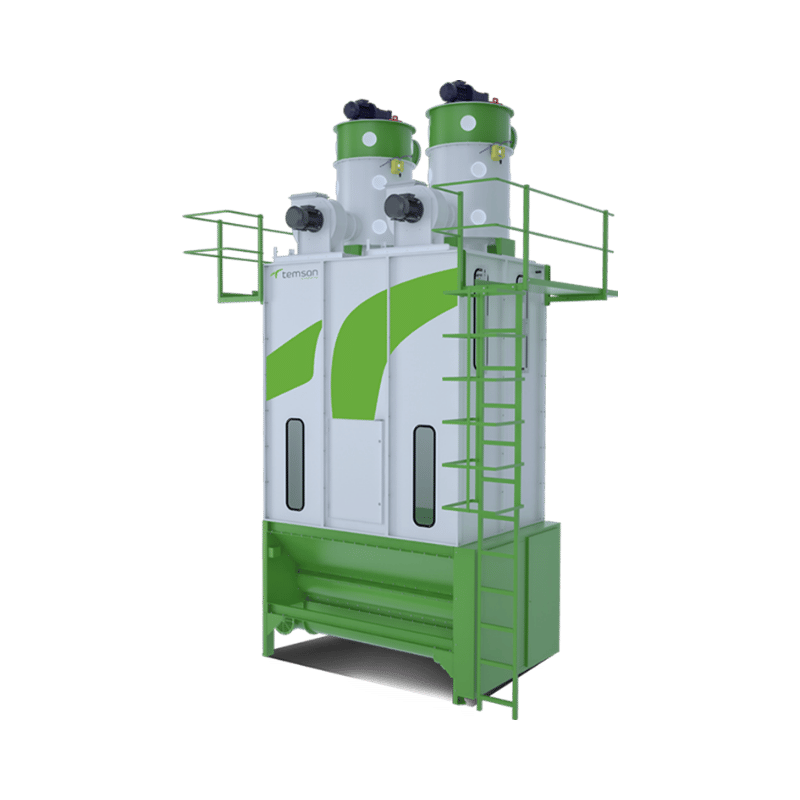

Clean air is vital for preventing contamination of fiber feed, ensuring proper airflow patterns, and protecting sensors.

- Removes Lint and Micro Particles From Fiber Channels

- Prevents Yarn Surface Defects and Sensor Malfunctions

- Reduces Maintenance Frequency of Airjet Nozzles

- Minimizes Cleaning Effort Around Machine Bases

Result: Smoother airflow, less downtime, and higher-quality yarns.

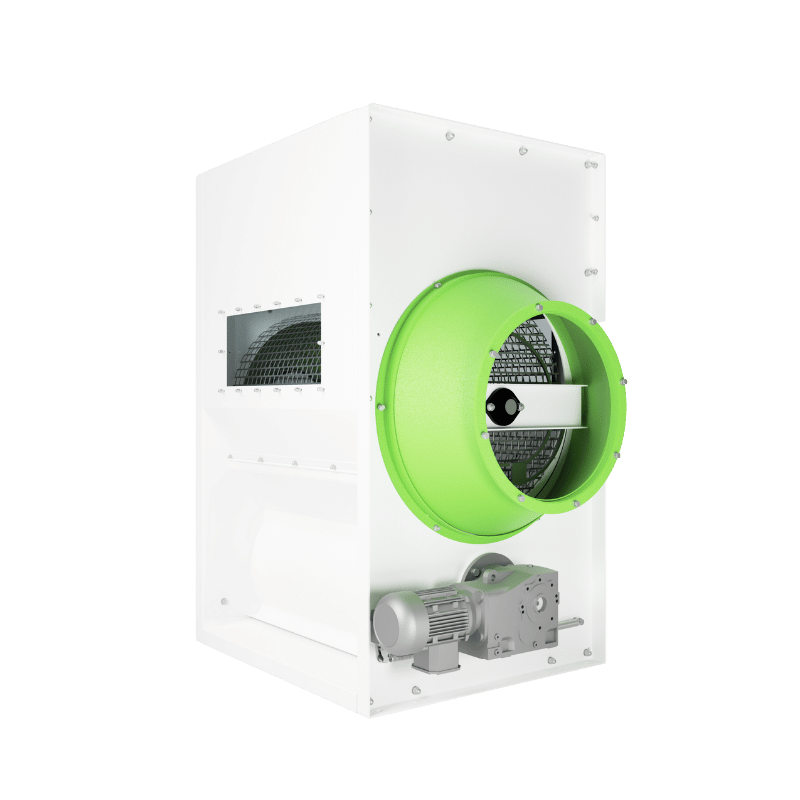

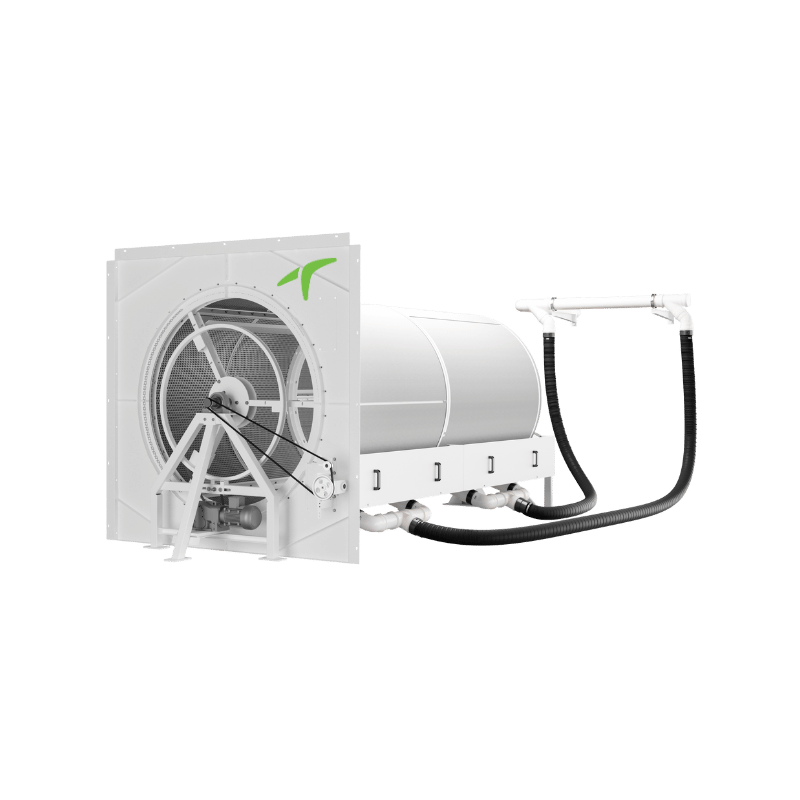

Temsan’s advanced fan and automation systems adjust airflow precisely to match production load — reducing energy waste without sacrificing performance.

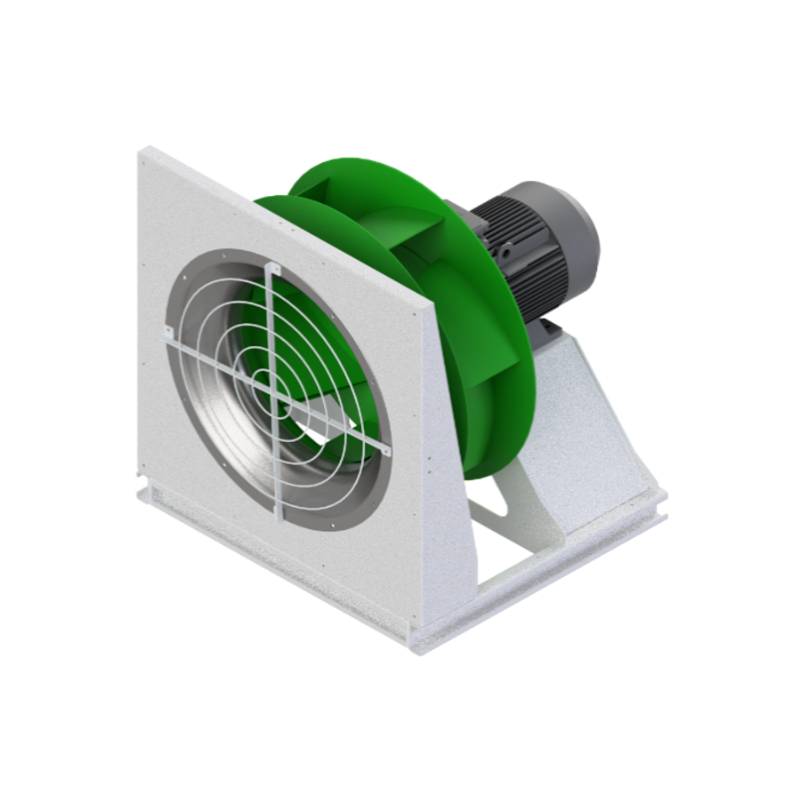

- Inverter-Based Axial Fans Ensure Demand-Responsive Flow

- Aircon Automation Optimizes RH and Air Volume in Real-Time

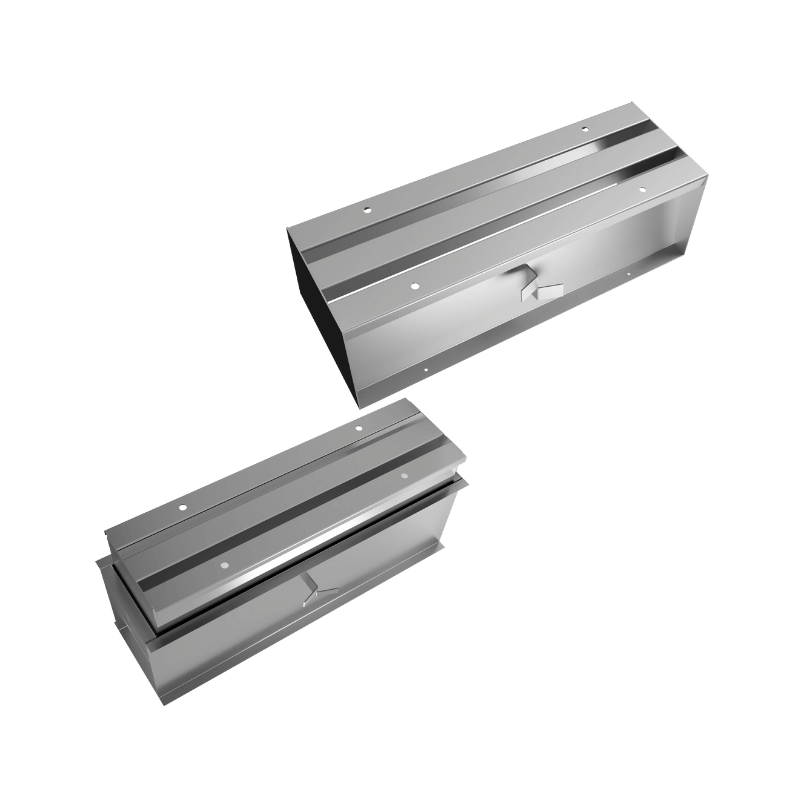

- Servo-Controlled Dampers Reduce Over-Conditioning

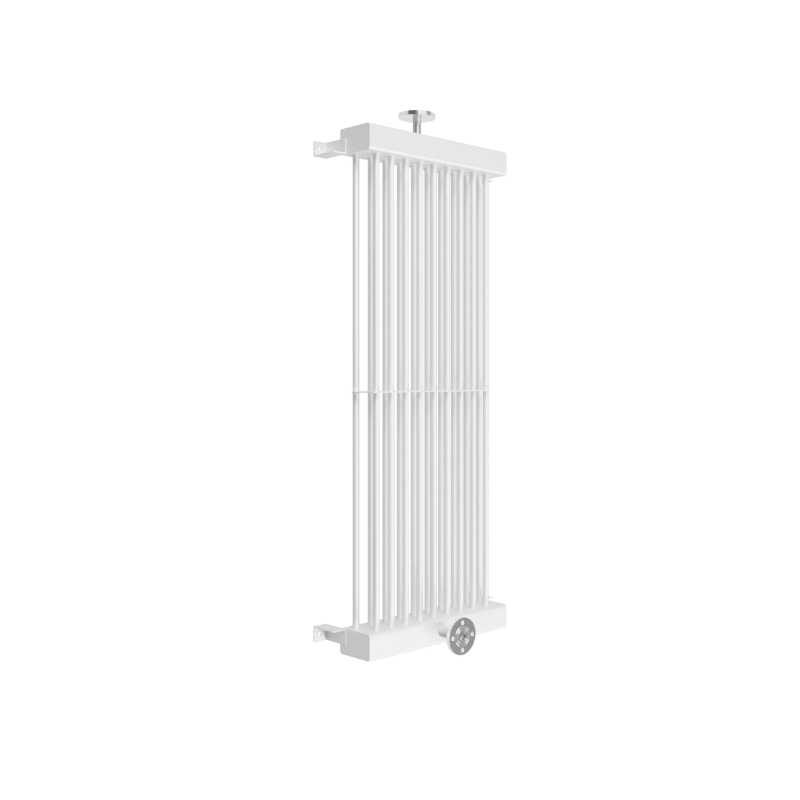

- Low-Pressure Air Washer Design for Efficient Humidification

Result: Lower utility costs and smarter control for high-speed lines.

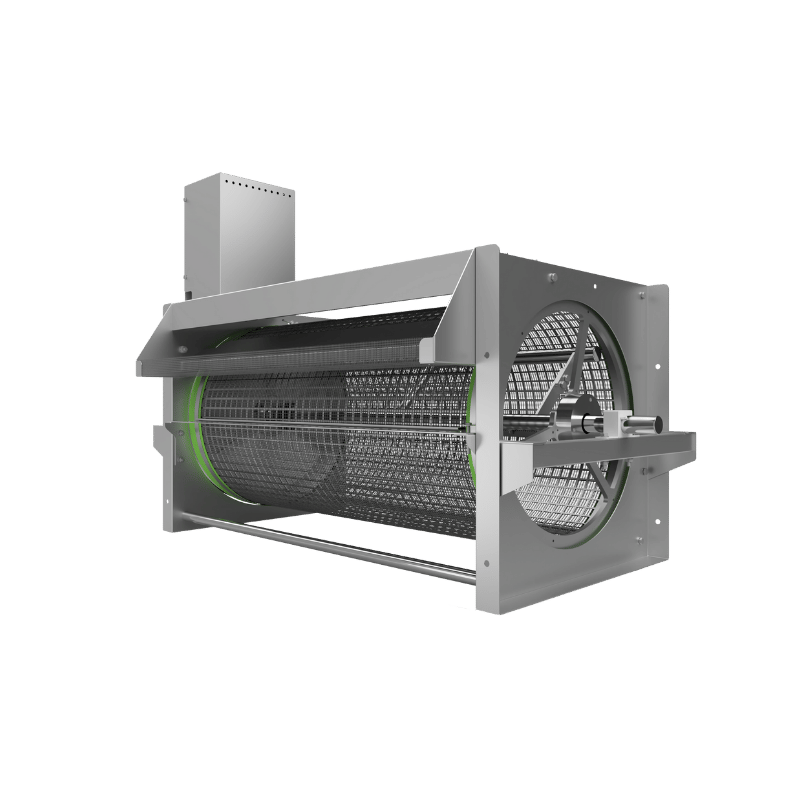

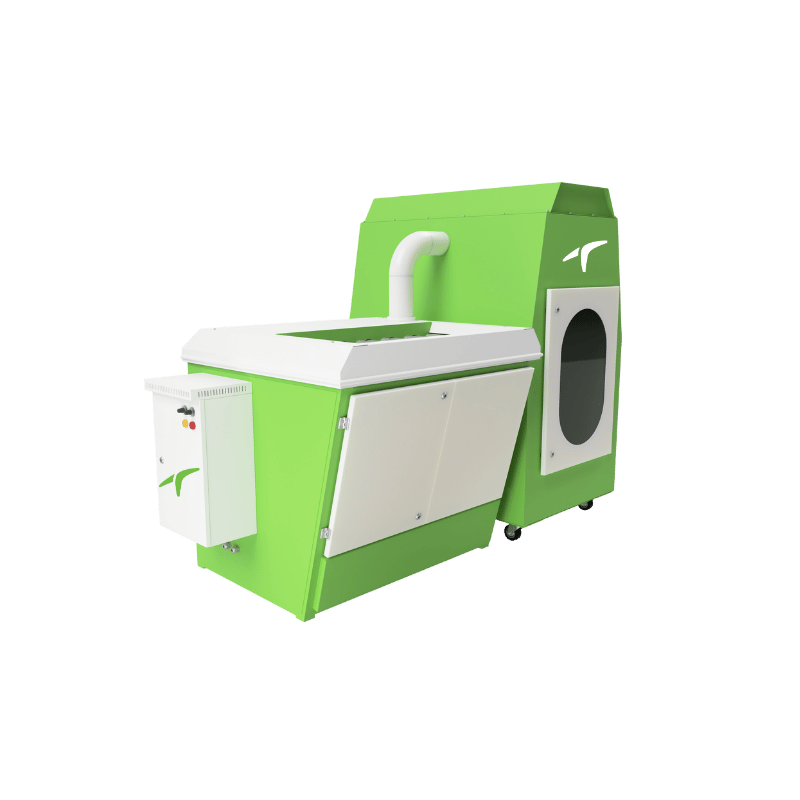

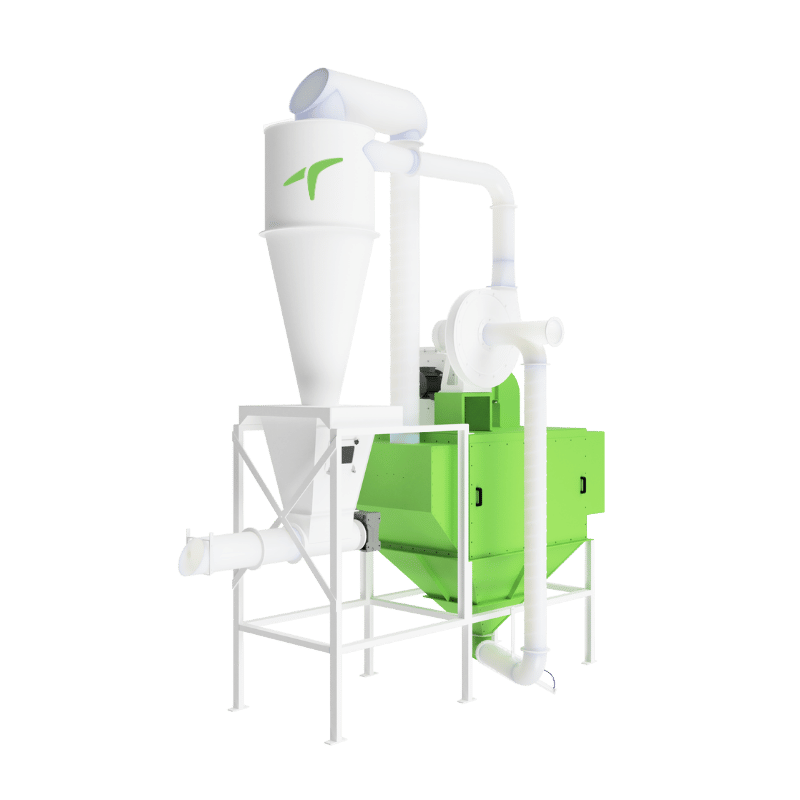

Exhaust Separation System

Developed by Temsan – Proven Since 2007

Temsan’s proprietary Exhaust Separation System is designed specifically for AIRJET & VORTEX spinning operations. It filters the hot exhaust air directly from the machines before it interacts with the hall’s return airflow.

Once filtered through the Rotary Filter, Temsan Aircon Automation intelligently determines whether the air should be:

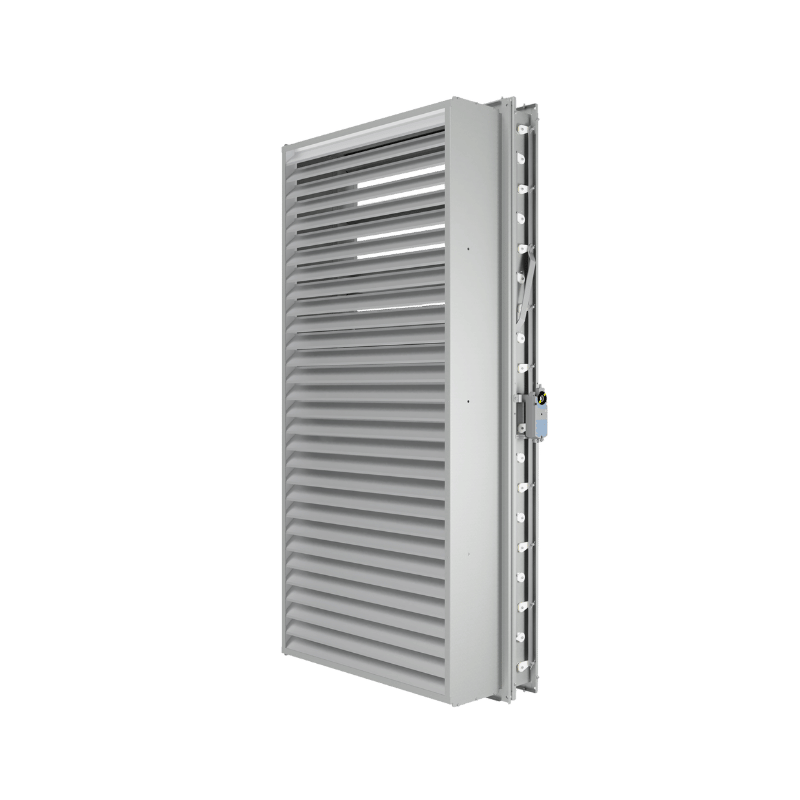

- 🌬️ Exhausted to outdoors through exhaust dampers

- ♻️ Reused by mixing with hall return air in front of the Air Washer

This smart routing prevents heat accumulation, enhances air quality, and boosts energy efficiency across the system.

- ✅ Filters machine exhaust at source

- ✅ Dynamic exhaust or reuse decision

- ✅ Fully automated via Aircon system

- ✅ Enhances energy and climate performance

Key Components of Temsan Air Conditioning and Filtration Systems

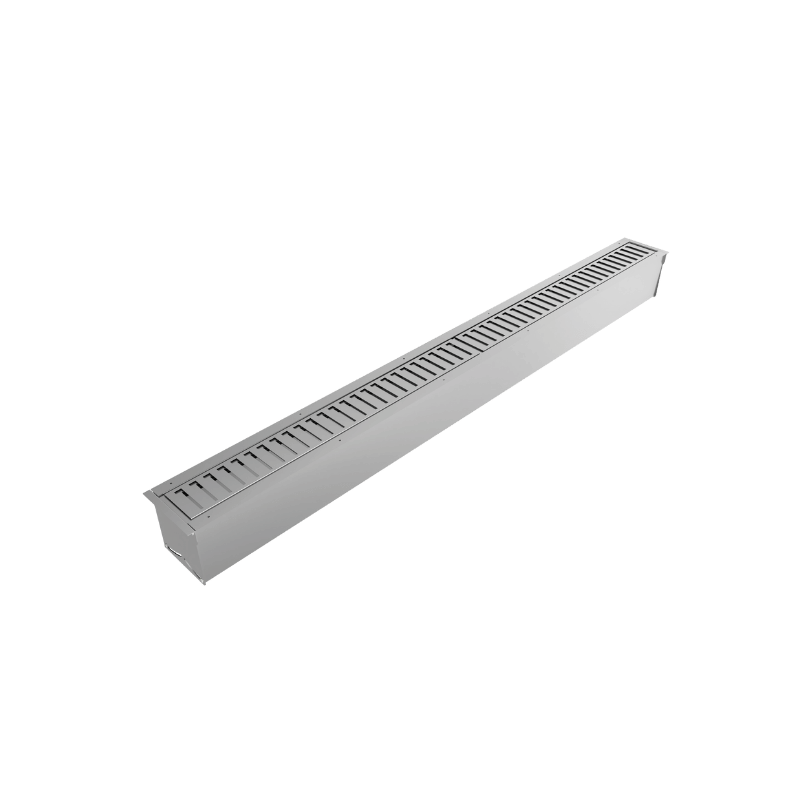

Filtration Components:

Air Conditioning Components:

Duct Design and Components

Integrated Waste & Dust Management for Spinning

Waste Management Automation

Dust Management Automation

TEMSAN AIRCON

- Real-time monitoring of temperature, humidity, and airflow

- Inverter-controlled axial fans for energy-efficient air delivery

- Servo dampers automatically balance fresh, exhaust, and return air

- Mobile and web-based access through Temsan Aircon platform

- Automatic and manual operation via HMI and SCADA interface

- Chiller & heating compatability with easy management

- Designed to run energy efficient to reduce your cost with higher productivity

Key Considerations in Textile A/C and Filtration Systems

High-Quality Products

Energy Efficiency