FINISHING MILLS APPLICATIONS

In the final stages of textile production, precise temperature, humidity, and air quality determine the quality of dyed, printed, or treated fabric. Temsan’s air conditioning and filtration systems are engineered to maintain stable conditions in stenter rooms, compacting lines, and all types of finishing halls — reducing defects, optimizing fabric handfeel, and enhancing energy efficiency.

Clean, Controlled Air for Flawless Fabric Finishing

Finishing lines demand tightly regulated air conditions for consistent results in drying, curing, and fabric stabilization. Below, you’ll find how temperature, humidity, air quality, and energy efficiency contribute to better finishing quality, reduced waste, and smoother operations.

Maintaining optimal humidity prevents fabric drying irregularities and ensures smooth processing through finishing machinery.

- Reduces Wrinkle Formation

- Improves Heat Setting Efficiency

- Minimizes Fiber Breakage in Mechanical Finishing

- Prevents Surface Cracking in Coating or Laminating

Result: Uniform appearance, softer handfeel, and less rejection.

Stable temperature control is crucial in stenter rooms and compactors where fabric curing, drying, and heat-setting occur.

- Improves Curing Accuracy

- Supports Uniform Fabric Shrinkage

- Prevents Overheating of Machinery

- Maintains Energy Efficiency of Heating Systems

Result: Higher production speed and process reliability.

Finishing lines are prone to fine particles, vapors, and lint. Efficient filtration and airflow management are essential for cleanliness and safety.

- Prevents Contaminant Accumulation on Fabric Surface

- Improves Drying Efficiency by Maintaining Clean Air

- Protects Operators from Dust and Chemical Particles

- Reduces Maintenance Needs on Sensors and Motors

Result: Cleaner working space and consistent fabric quality.

Temsan’s automation and ducting design help reduce energy use in high-heat and high-humidity finishing zones.

- Minimizes Energy Spikes During Fabric Entry & Exit

- Synchronizes Air Supply with Machine Load

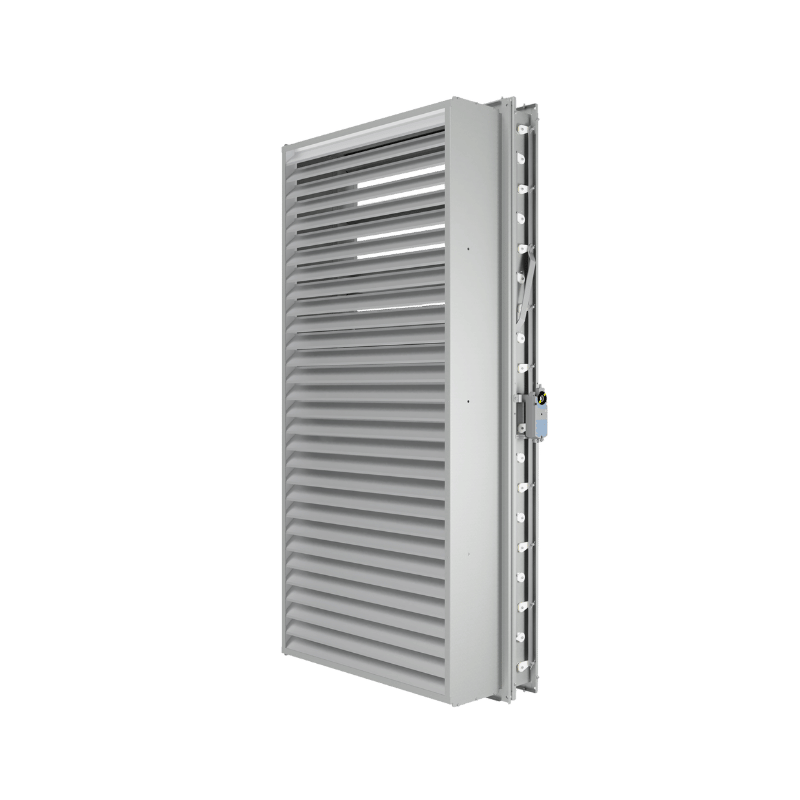

- Reduces Heat Loss through Controlled Exhaust Dampers

- Lowers HVAC Cost with Smart Humidity Management

Result: Lower production cost and optimized energy profile.

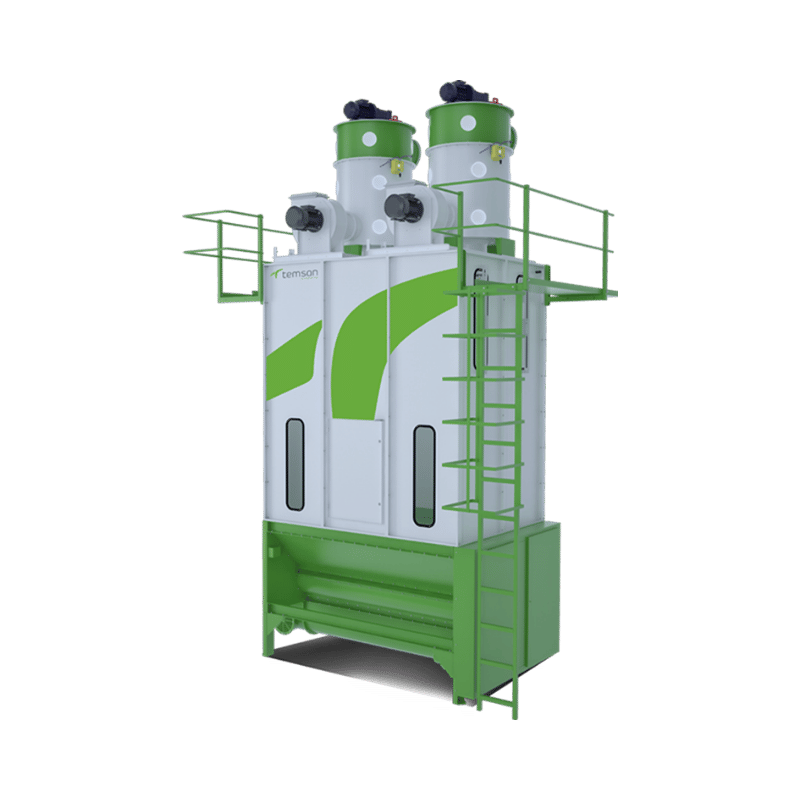

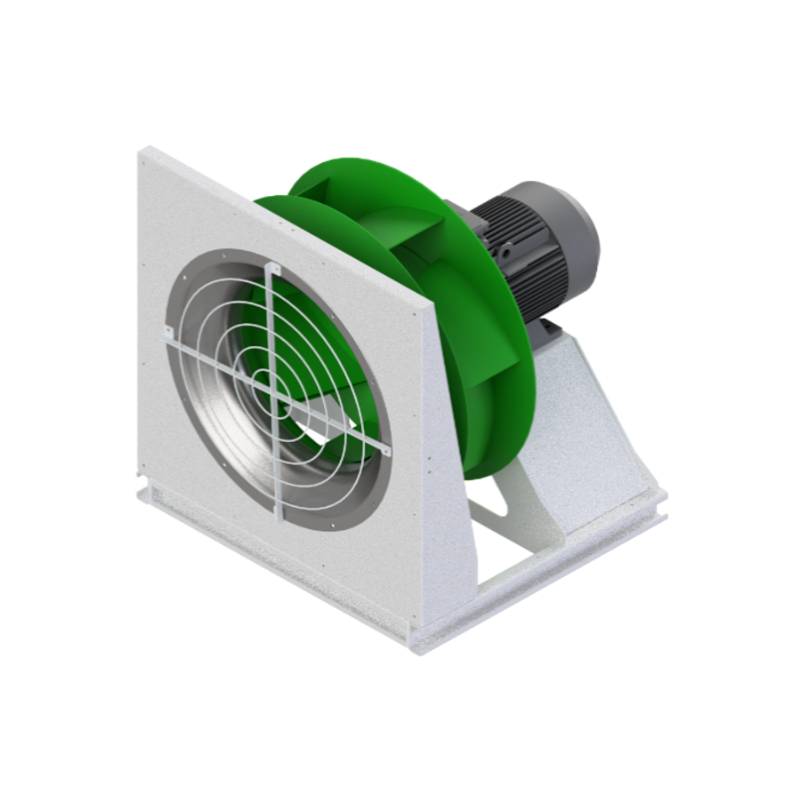

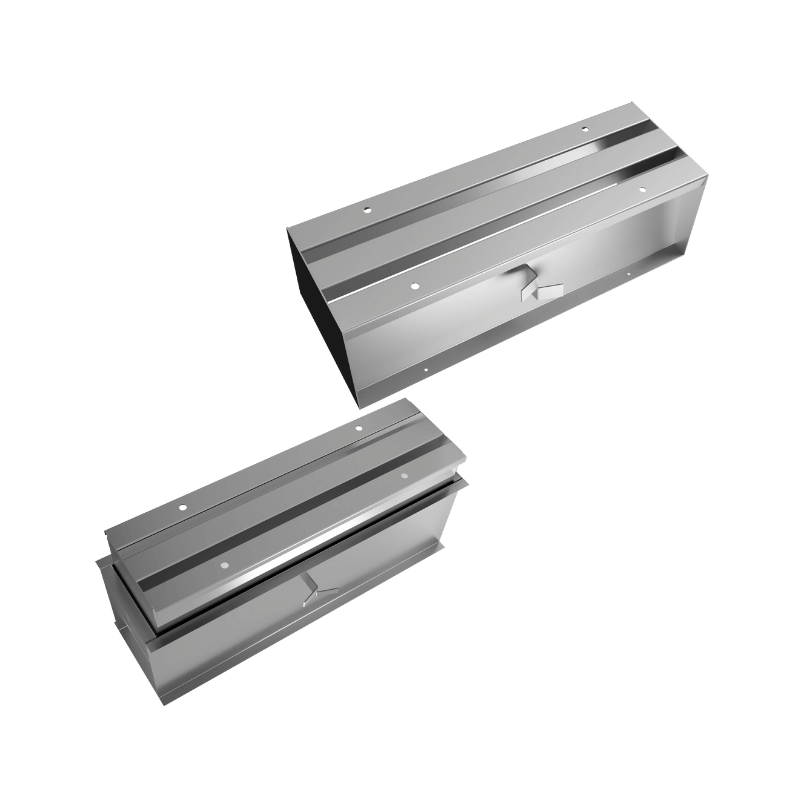

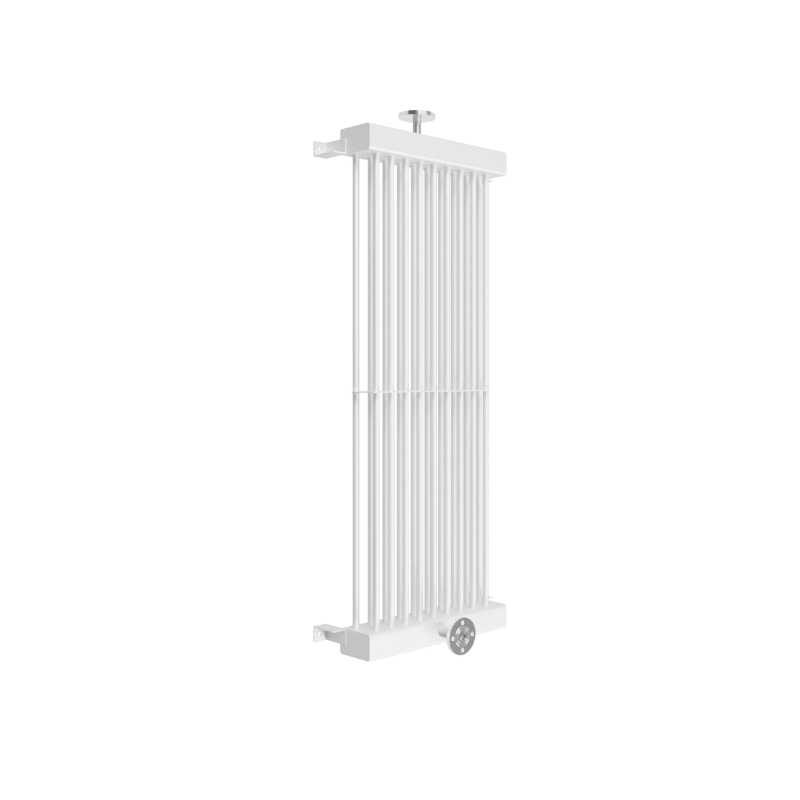

Key Components of Temsan Air Conditioning and Filtration Systems

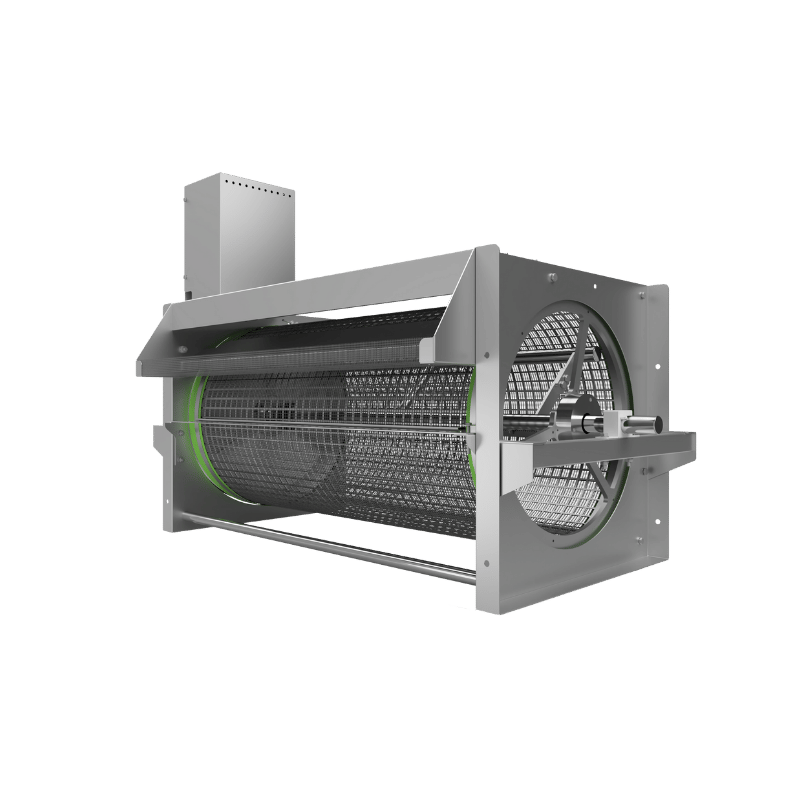

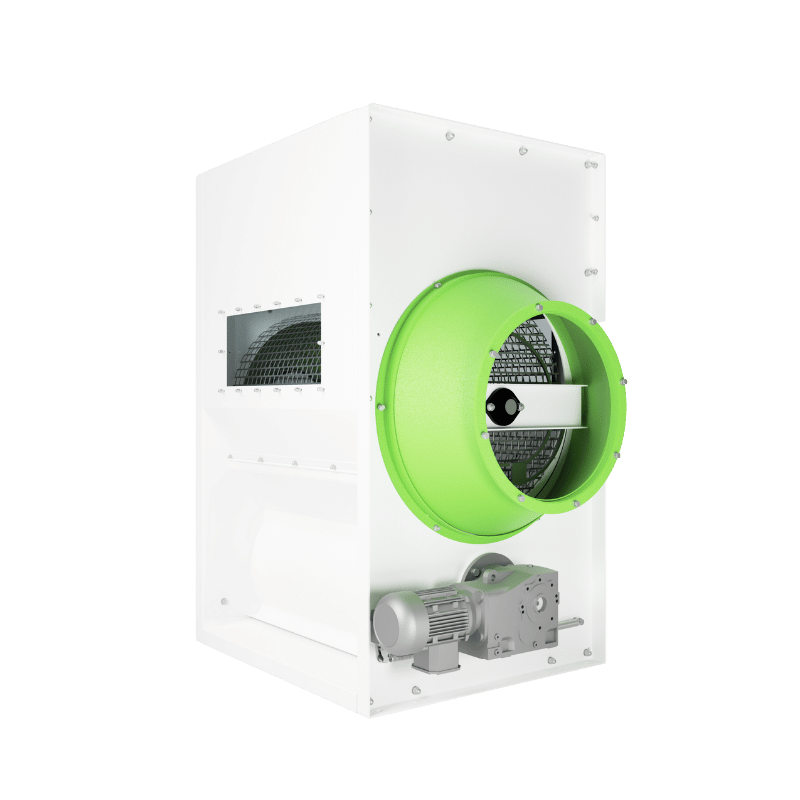

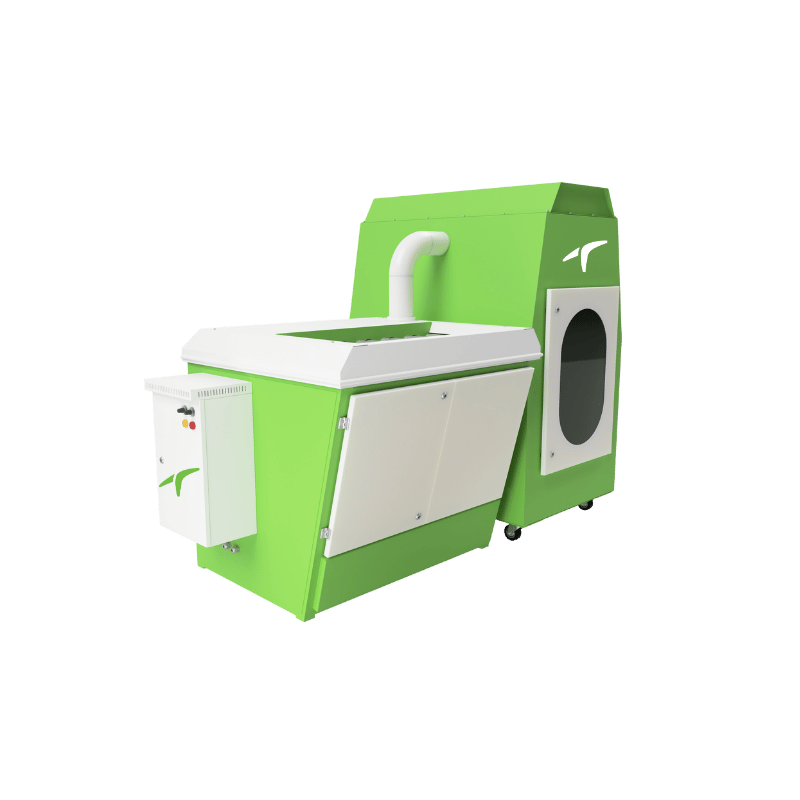

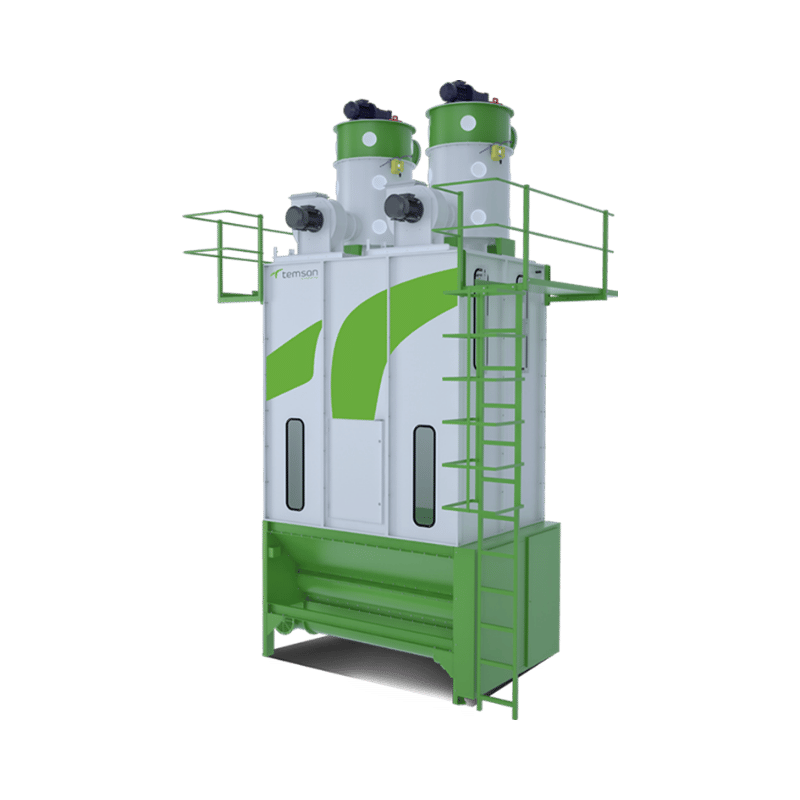

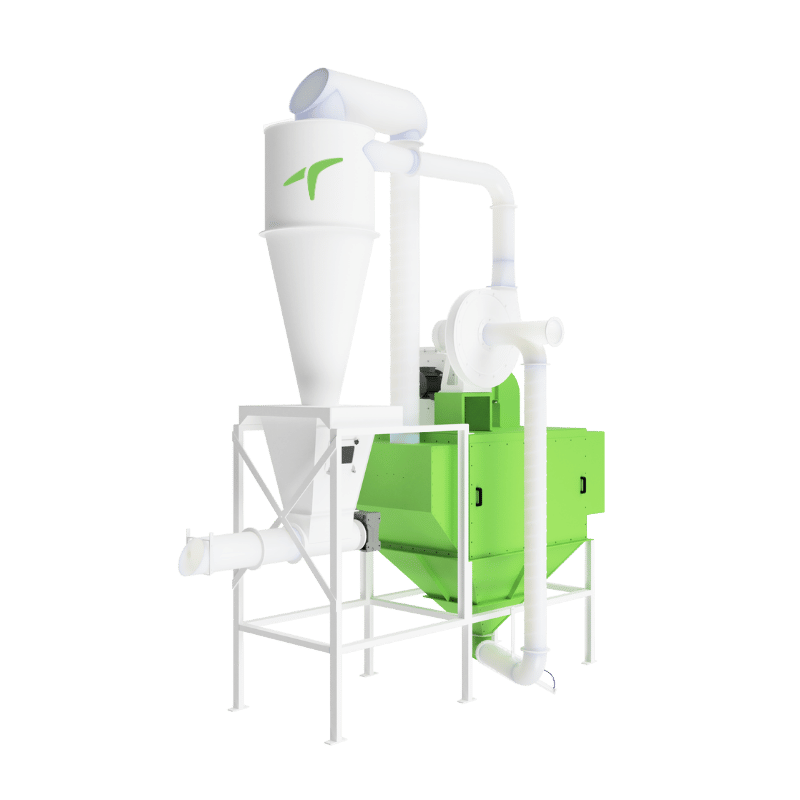

Filtration Components:

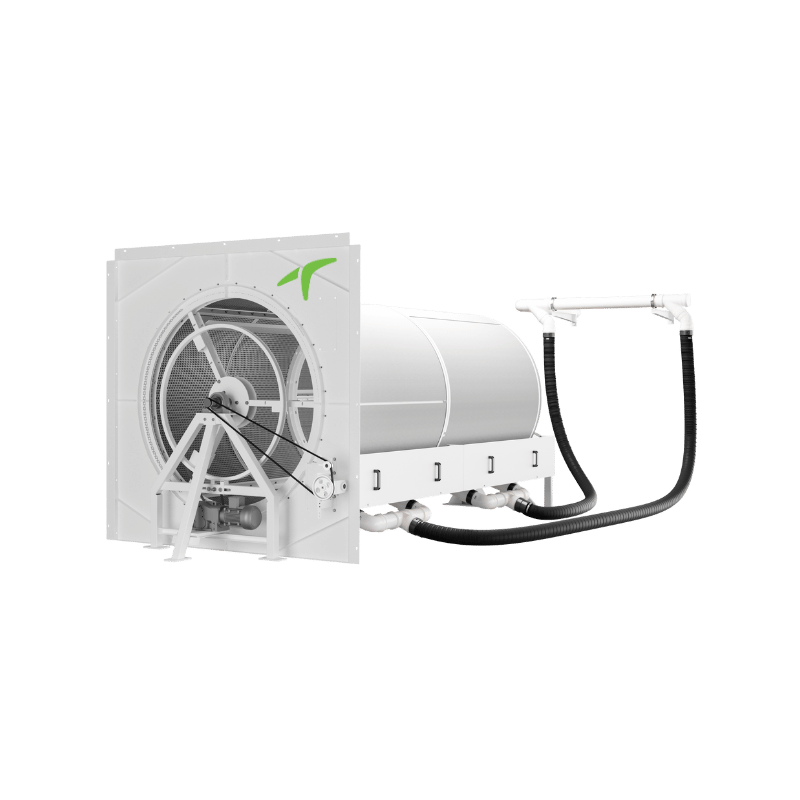

Air Conditioning Components:

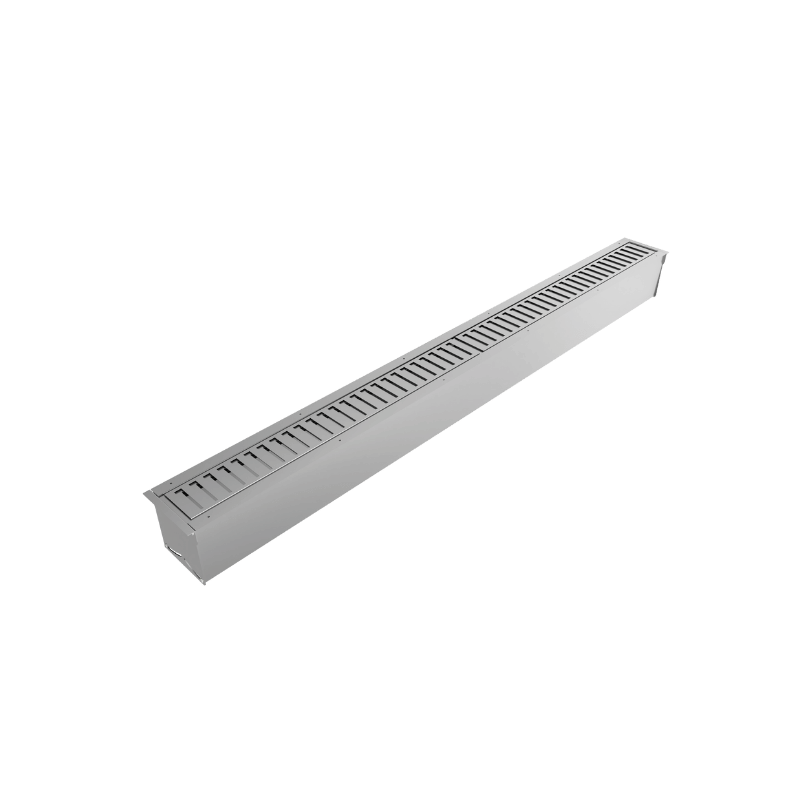

Duct Design and Components

Integrated Waste & Dust Management for Spinning

Waste Management Automation

Dust Management Automation

TEMSAN AIRCON

- Real-time monitoring of temperature, humidity, and airflow

- Inverter-controlled axial fans for energy-efficient air delivery

- Servo dampers automatically balance fresh, exhaust, and return air

- Mobile and web-based access through Temsan Aircon platform

- Automatic and manual operation via HMI and SCADA interface

- Chiller & heating compatability with easy management

- Designed to run energy efficient to reduce your cost with higher productivity

Key Considerations in Textile A/C and Filtration Systems

High-Quality Products

Energy Efficiency