KNITTING APPLICATIONS

Knitting processes generate airborne fibers, heat, and static, all of which can disrupt production if not properly managed. Temsan’s air conditioning and filtration systems are engineered to ensure consistent air quality, controlled humidity, and energy-saving airflow — keeping knitting operations stable, clean, and efficient.

Optimizing Air Conditioning for Knitting Efficiency

Maintaining proper humidity, temperature, air quality, and energy balance is essential in Knitting halls. Below, you’ll find how each of these factors contributes to better fabric quality, lower costs, and higher machine efficiency.

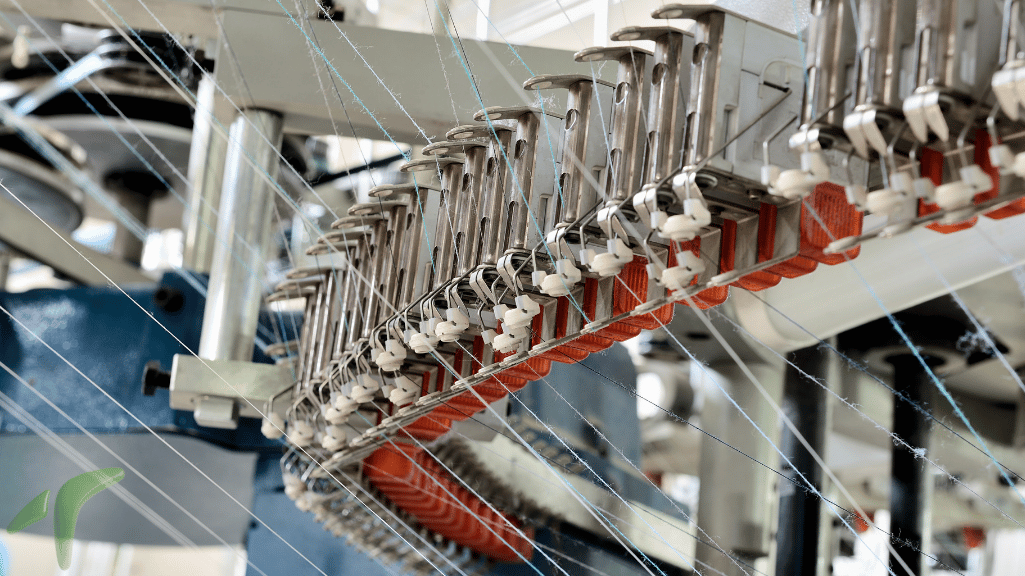

Controlling humidity in weaving halls is vital for preventing yarn breakage, ensuring tension stability, and minimizing electrostatic issues on high-speed looms.

- Reduces Static Build-Up: Prevents discharge disruptions between yarns and components.

- Improves Warp Tension Consistency: Helps maintain uniform thread behavior under load.

- Minimizes Yarn Hairiness: Reduces surface friction and fiber abrasion during weaving.

- Supports Smoother Loom Operation: Less jerking or skipping caused by dry fibers.

- Prevents Dust Adhesion: Keeps lint from sticking to warp guides, sensors, or reed areas.

- Stabilizes Moisture Retention in Fibers: Avoids brittle yarn under tension.

Result: Improved loom efficiency, fewer thread breaks, and higher fabric quality.

Maintaining stable temperatures helps preserve yarn elasticity, prevent warping, and avoid machine strain in high-speed weaving environments.

- Prevents Yarn Shrinkage or Deformation: Ensures dimensional stability across batches.

- Minimizes Thermal Stress on Machine Parts: Reduces wear on bearings and drive systems.

- Controls Heat-Induced Static: Keeps electrostatic charges in check under high-speed conditions.

- Improves Yarn Feed Consistency: Prevents stiffening or loosening of bobbins and warp beams.

- Supports Airflow Precision: Ensures pre-set flow and RH targets are maintained accurately.

- Enhances Operator Comfort: Improves focus and handling in extended shifts.

Result: Better yarn handling, consistent weaving speeds, and improved machine longevity.

Clean, filtered air in weaving halls ensures uninterrupted sensor performance, reduces fiber buildup, and maintains a controlled production atmosphere.

- Removes Airborne Fiber Fly: Prevents lint from settling on optical sensors and motion detectors.

- Reduces Contamination: Ensures clean warp threads and fabric surfaces.

- Improves Shed Clarity: Keeps air movement steady within the warp zone.

- Prevents Yarn Tracking Errors: Keeps cameras, laser stops, and photocells free from obstruction.

- Minimizes Cleaning Cycles: Reduces downtime due to clogged ducts and lint accumulation.

- Protects Sensitive Electronics: Avoids short-circuiting or damage in automatic looms.

Result: Higher-quality output, less unplanned maintenance, and smoother automation performance.

Energy-efficient air systems reduce operational costs, optimize system responsiveness, and align with modern sustainability goals in textile production.

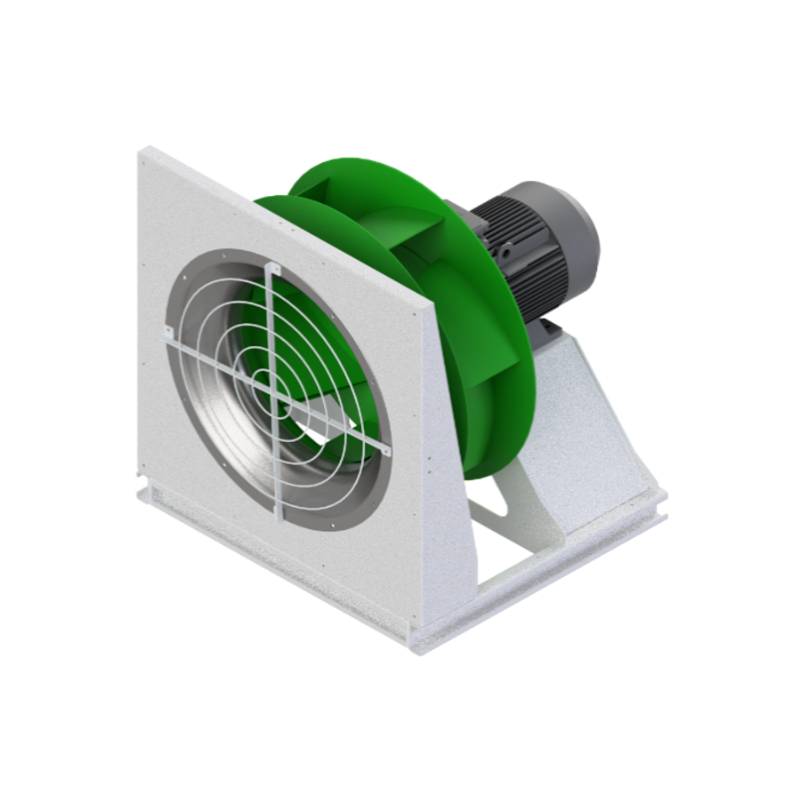

- Inverter-Controlled Fan Systems: Reduce energy consumption based on hall demand.

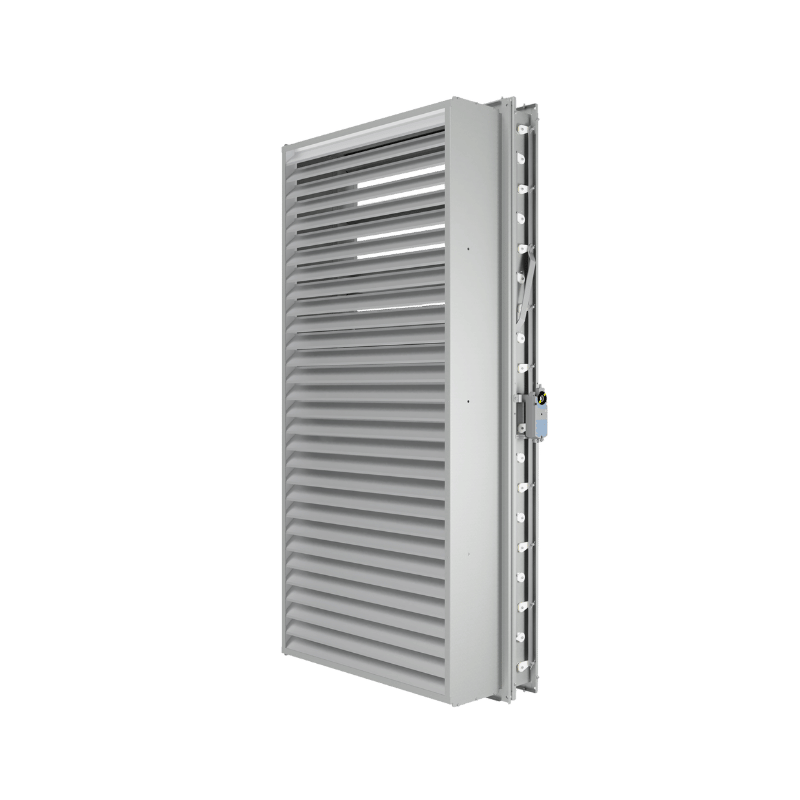

- Smart Damper Control: Balances fresh and return air intake based on process conditions.

- Zone-Based Automation: Only conditions active weaving areas, avoiding waste.

- Low Static Pressure Air Washers: Provide humidity with minimal power load.

- Reduced Filter Load: Less clogging, fewer replacements, and lower fan pressure requirements.

- Centralized Monitoring: Aircon Automation ensures predictive energy adjustment.

Result: Lower energy bills, better system control, and reduced environmental impact.

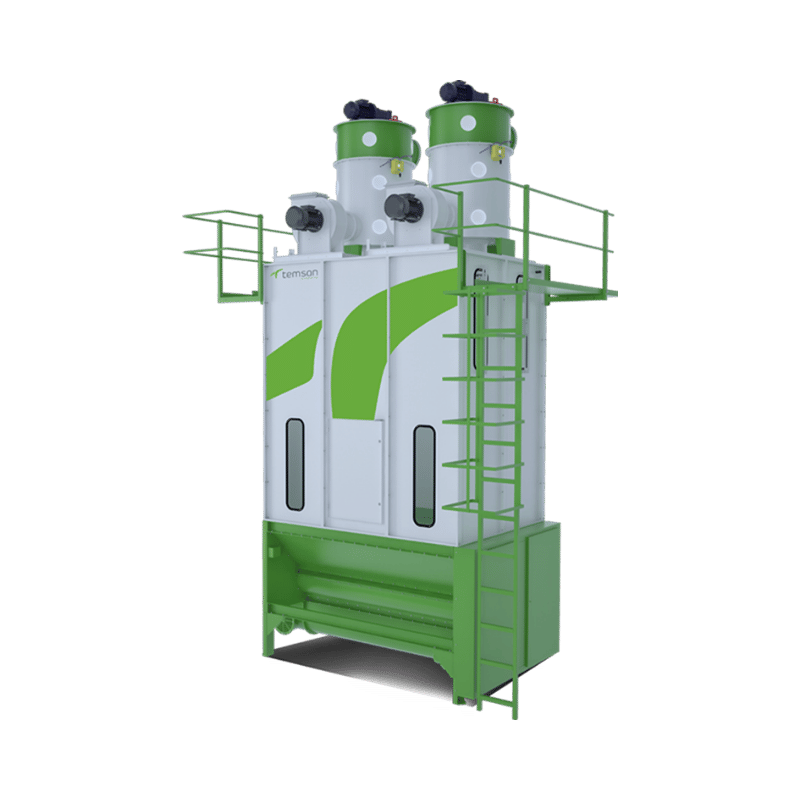

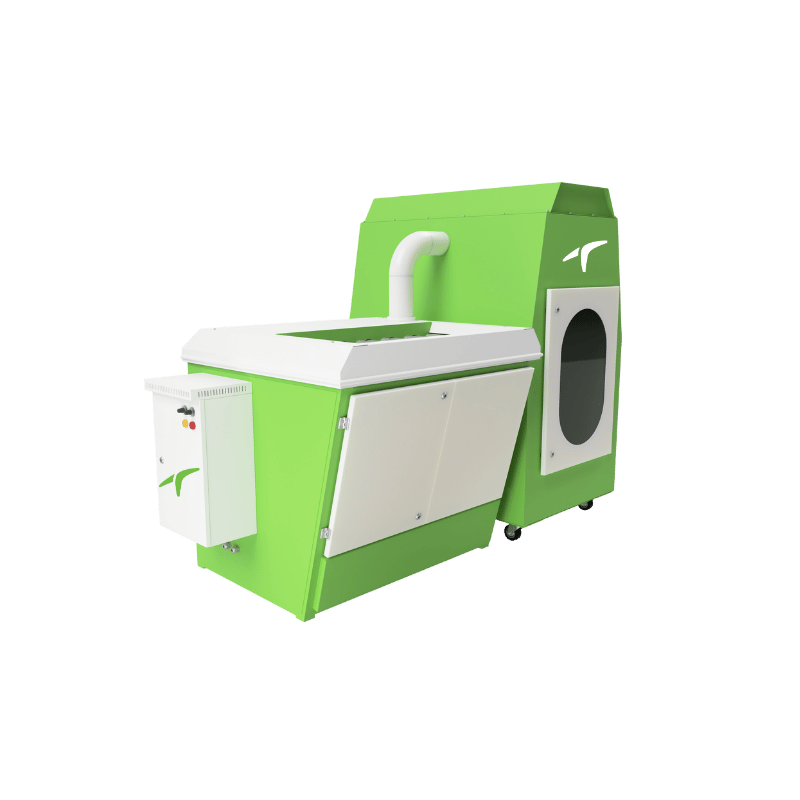

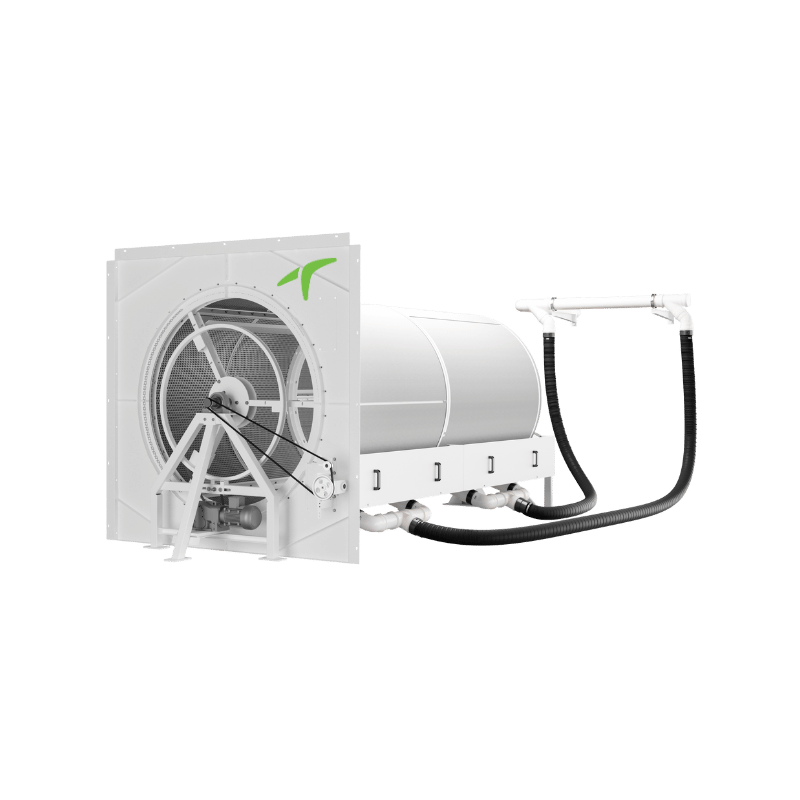

Key Components of Temsan Air Conditioning and Filtration Systems

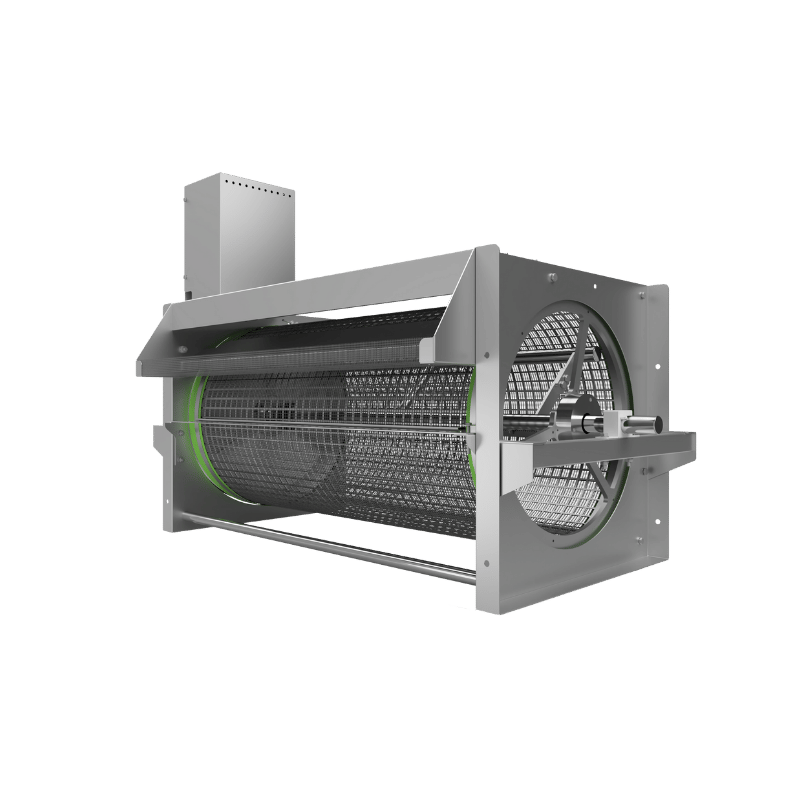

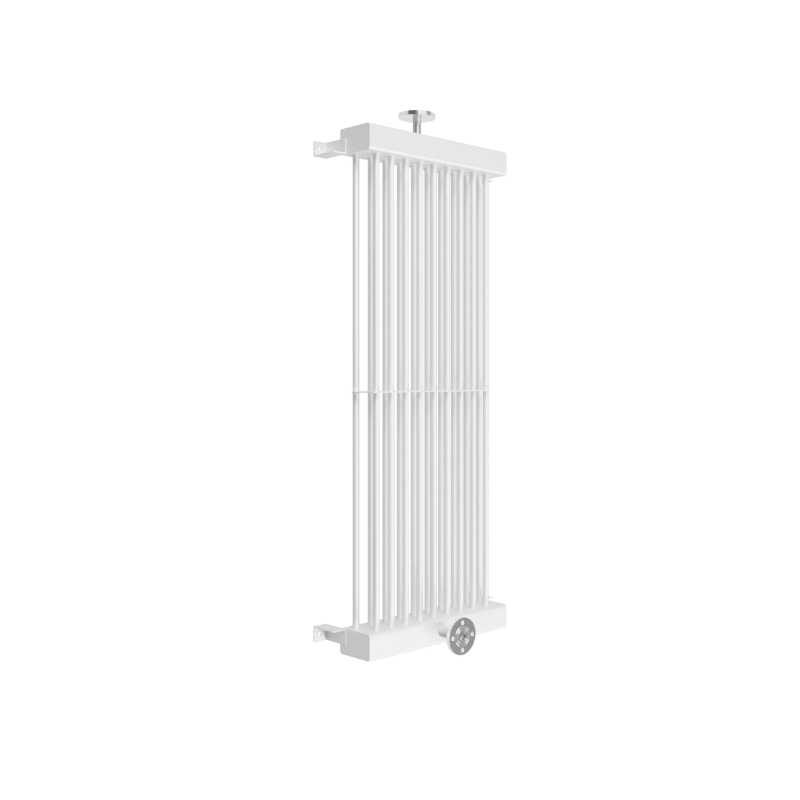

Filtration

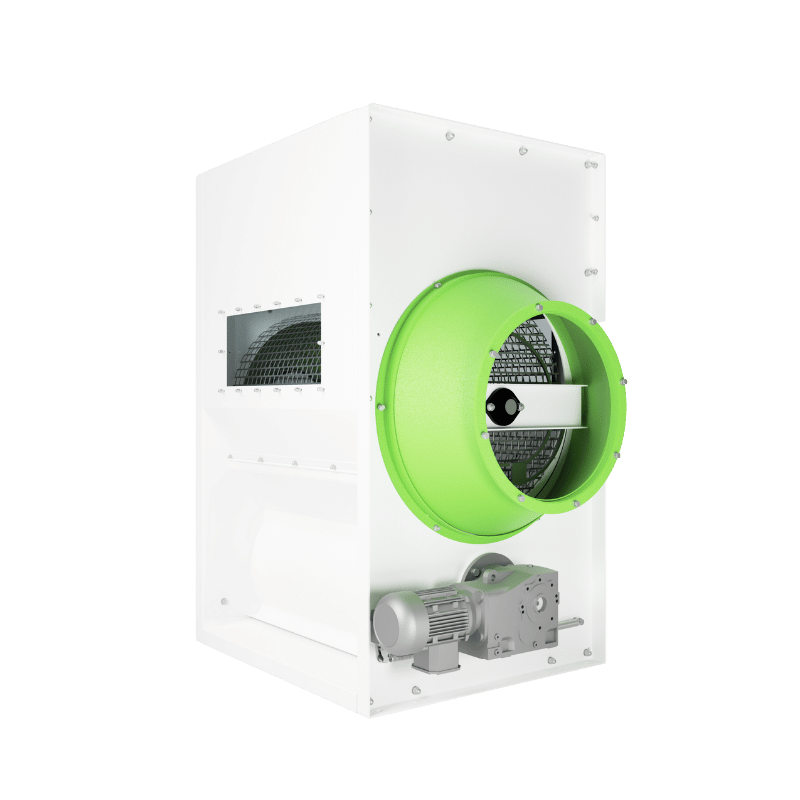

Air Conditioning

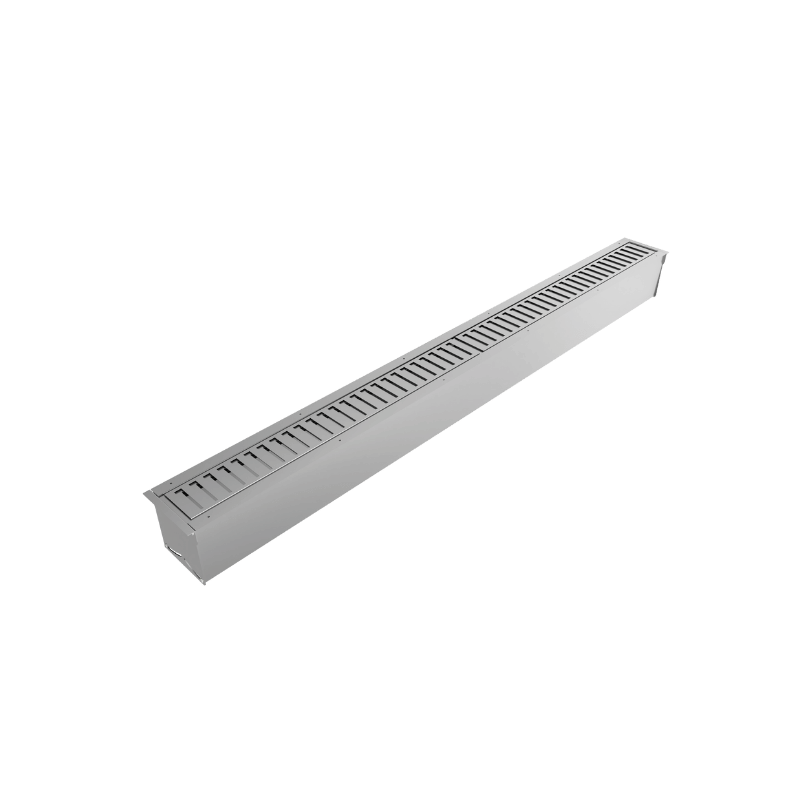

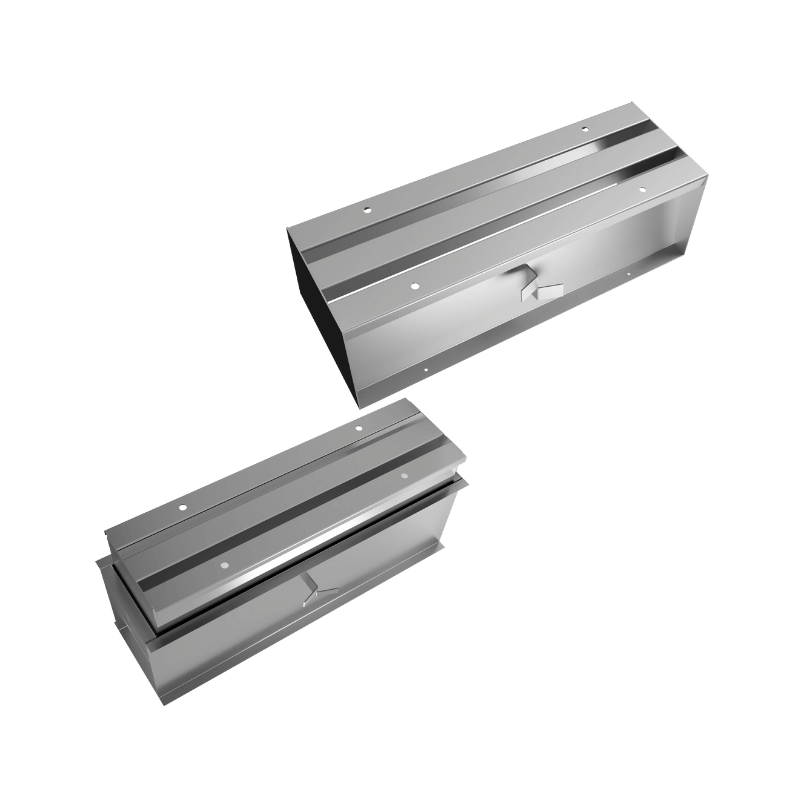

Duct Design

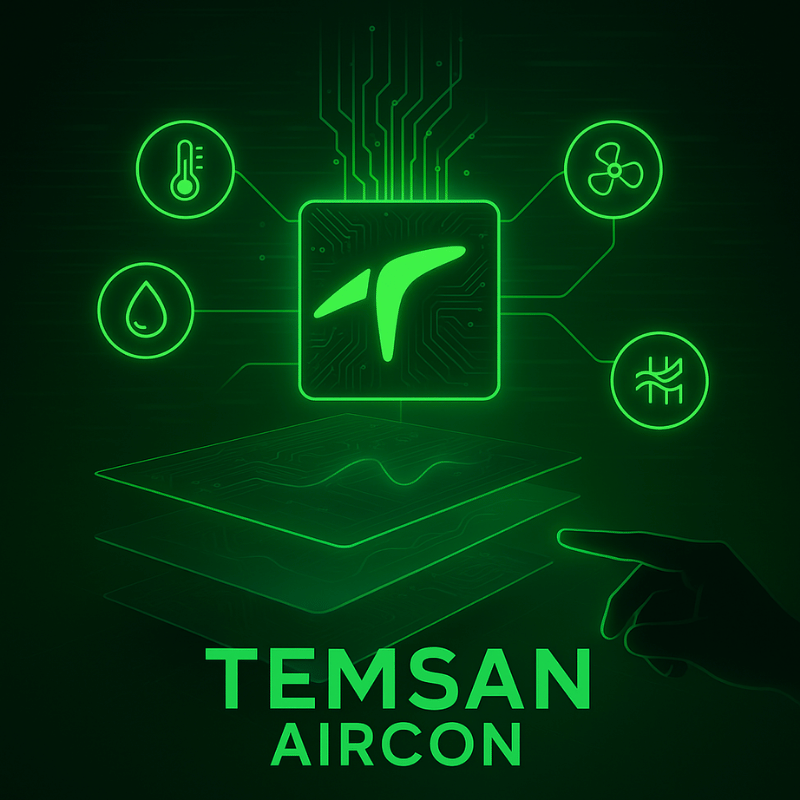

TEMSAN AIRCON

- Real-time monitoring of temperature, humidity, and airflow

- Inverter-controlled axial fans for energy-efficient air delivery

- Servo dampers automatically balance fresh, exhaust, and return air

- Mobile and web-based access through Temsan Aircon platform

- Automatic and manual operation via HMI and SCADA interface

- Chiller & heating compatability with easy management

- Designed to run energy efficient to reduce your cost with higher productivity

Key Considerations in Textile A/C and Filtration Systems

High-Quality Products

Energy Efficiency