POY

(Partially Oriented Yarn)

APPLICATIONS

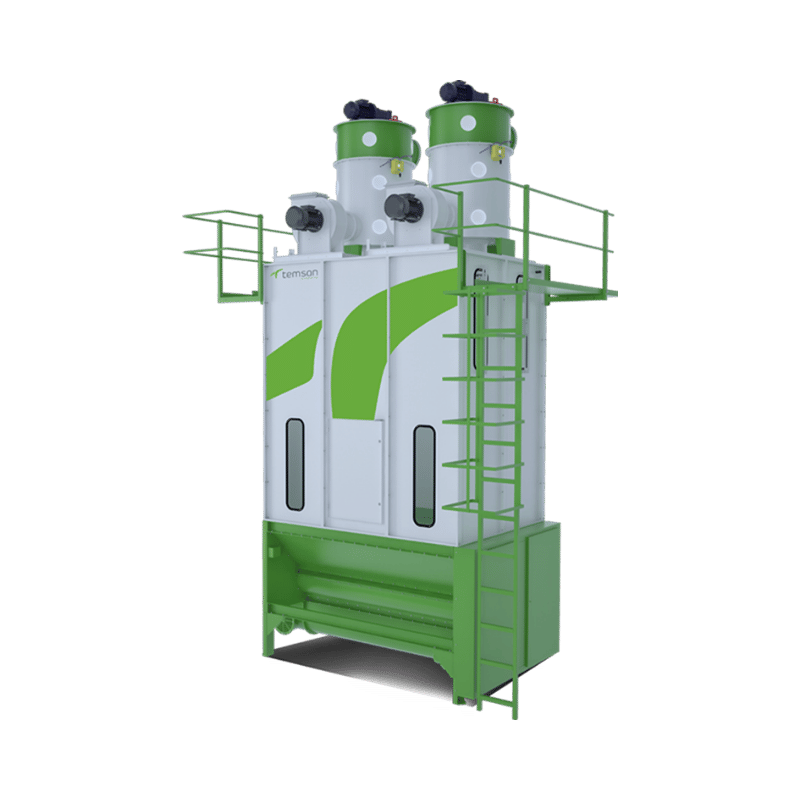

POY spinning requires tightly controlled air conditions to ensure fiber consistency, prevent defects, and maintain uninterrupted operation. Temsan’s air conditioning and filtration systems are designed to stabilize cooling zones, manage humidity, and eliminate airborne contamination — delivering higher quality yarn and energy-efficient production in continuous operations.

Optimized Air Systems for Polyester Yarn Production

Maintaining proper humidity, temperature, air quality, and energy balance is essential in POY spinning halls. These factors directly affect yarn orientation, break rates, and cooling stability. Below, you’ll find how each contributes to quality, reliability, and energy savings in polyester yarn production.

Humidity must be tightly controlled to prevent static buildup and filament separation in POY spinning.

- Reduces Electrostatic Charges in Spinning Columns

- Improves Yarn Cohesion During Orientation

- Prevents Filament Entanglement or Fly Movement

- Supports Smooth Yarn Transfer to Winding

Result: Reduced thread breaks, better package build-up, and improved downstream draw performance.

Consistent air temperature ensures stable cooling and orientation of polyester filaments during high-speed spinning.

- Stabilizes Cooling Air Flow Around Yarn Columns

- Minimizes Yarn Diameter Fluctuations

- Prevents Thermal Stress on Guides and Winders

- Enhances Heat Dissipation from Motors and Control Panels

Result: Uniform yarn tension, reduced off-quality, and extended machine life.

Clean air is essential for minimizing yarn contamination and maintaining optical sensor accuracy throughout the POY process.

- Prevents Fly Fiber Buildup Around Spinnerets and Guides

- Protects Photoelectric Sensors and Monitoring Devices

- Keeps Floors and Machines Cleaner for Longer

- Reduces Maintenance Needs Around Air Handling Units

Result: Fewer false yarn stops, better quality monitoring, and reduced cleaning frequency.

Temsan’s automation and low-resistance airflow design help POY facilities manage energy use even during 24/7 production.

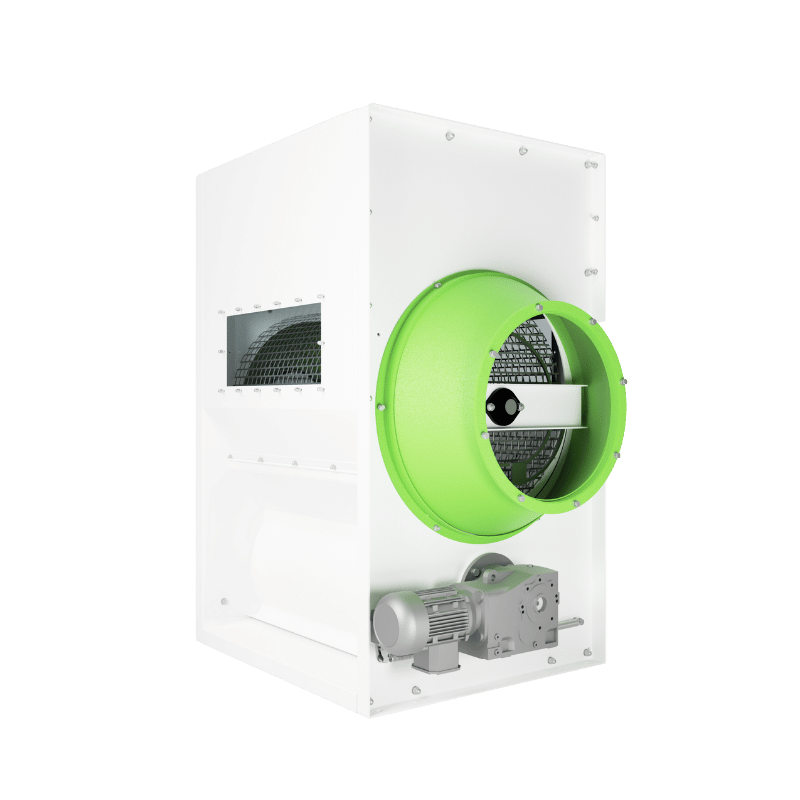

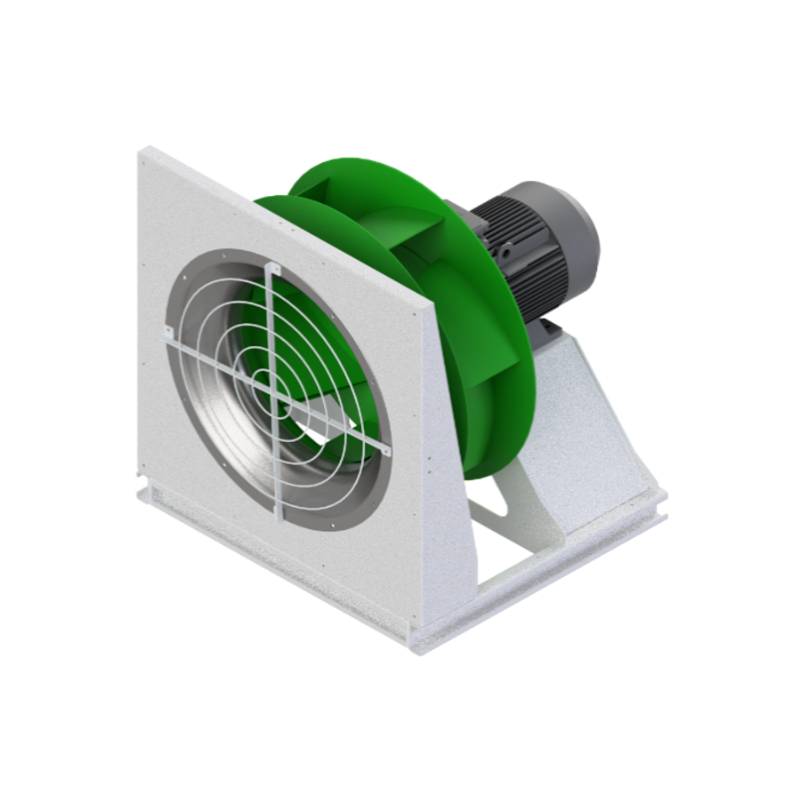

- Inverter-Controlled Axial Fans for Demand-Based Operation

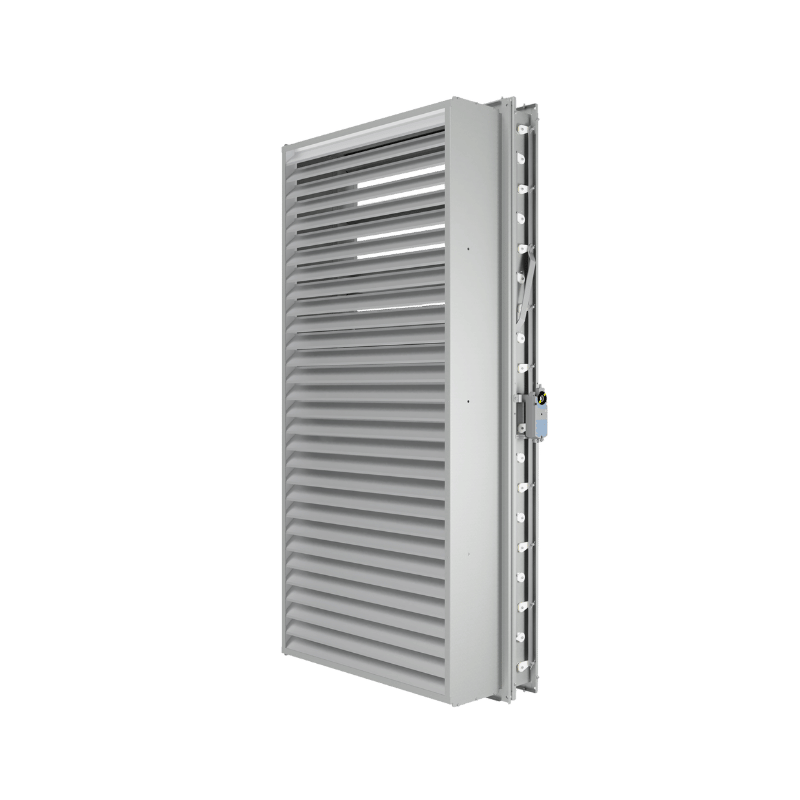

- Servo Dampers Adapt to External Climate and Load

- Efficient Air Washers Operate at Low Static Pressure

- Aircon Automation Enables Real-Time Energy Tracking

Result: Reduced electricity consumption and more stable energy budgeting across all shifts.

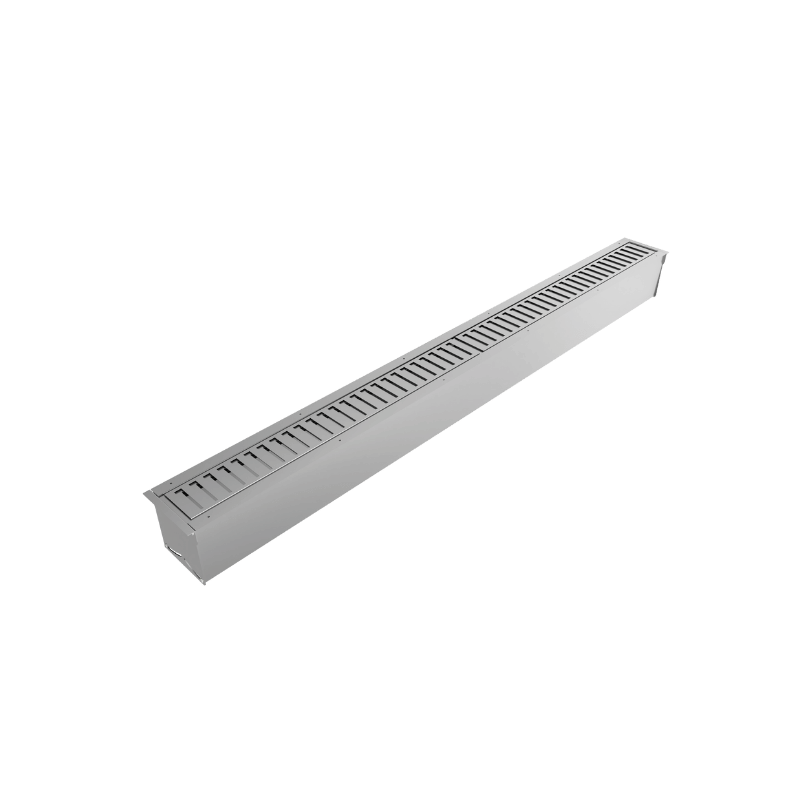

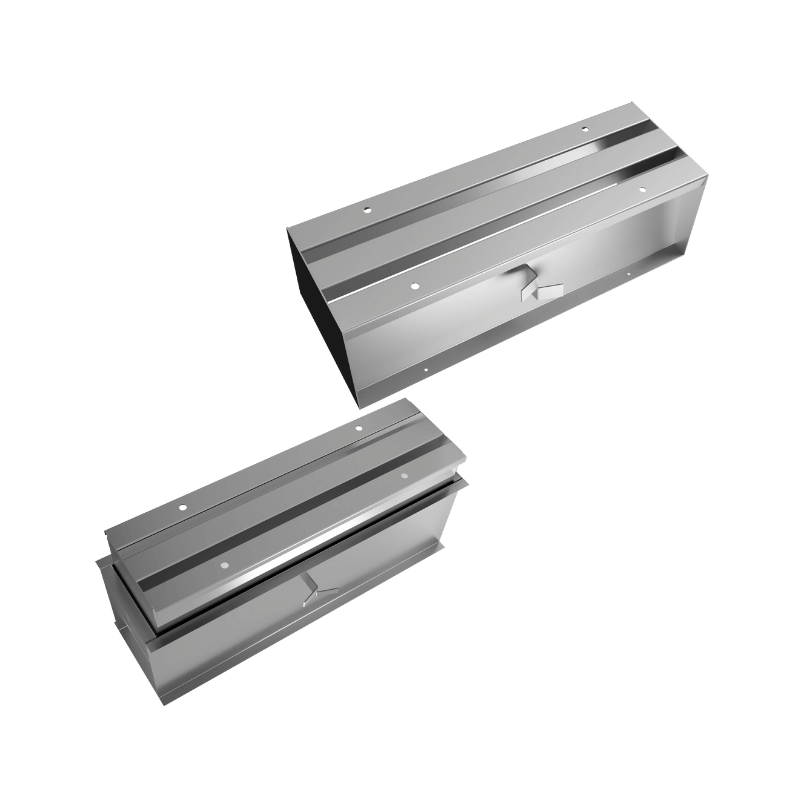

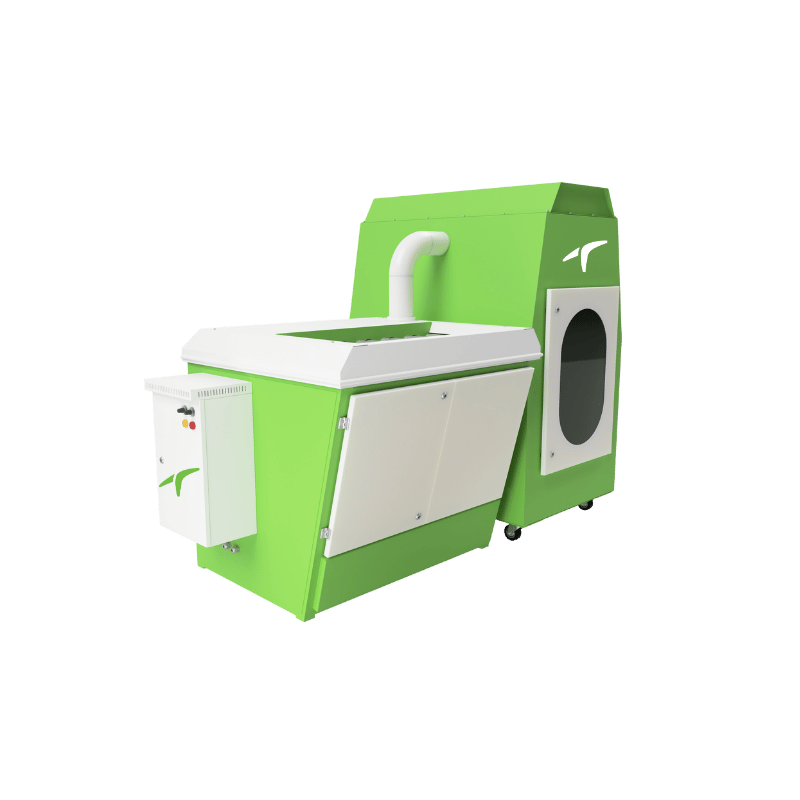

DUCT TYPE DIFFUSER

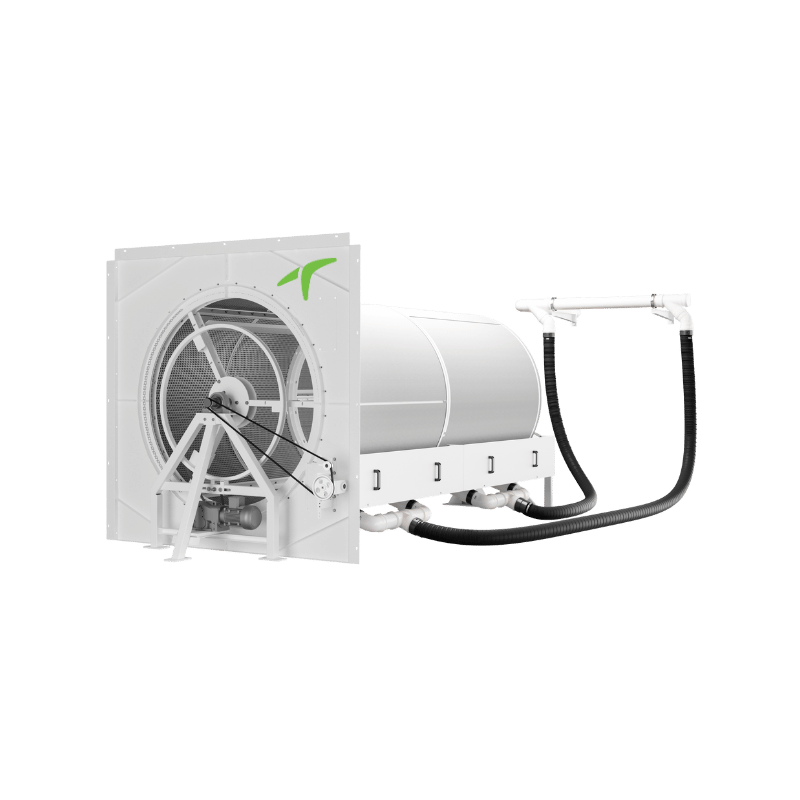

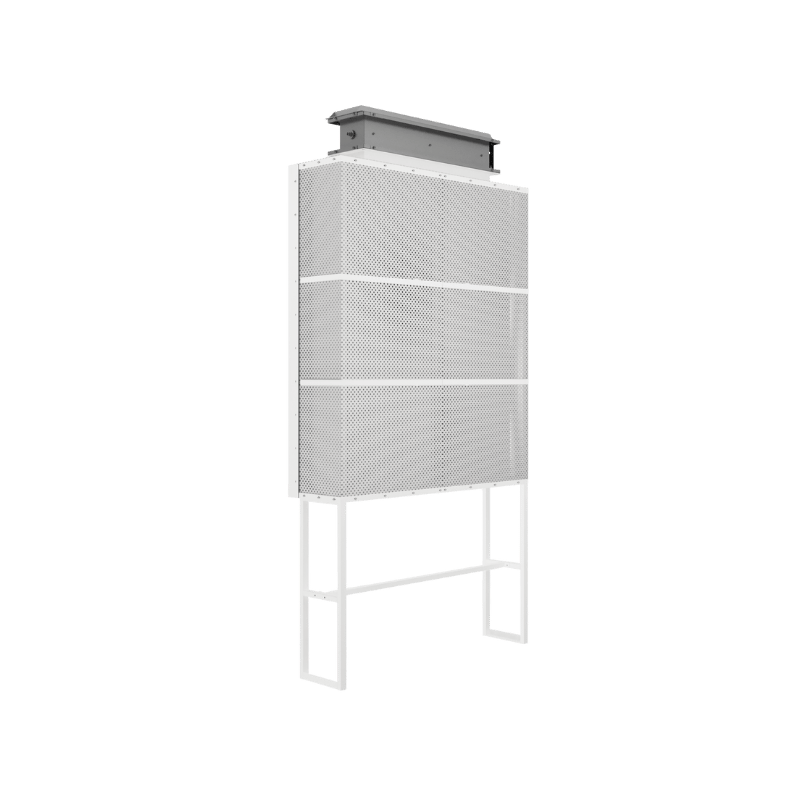

Key Components of Temsan Air Conditioning and Filtration Systems

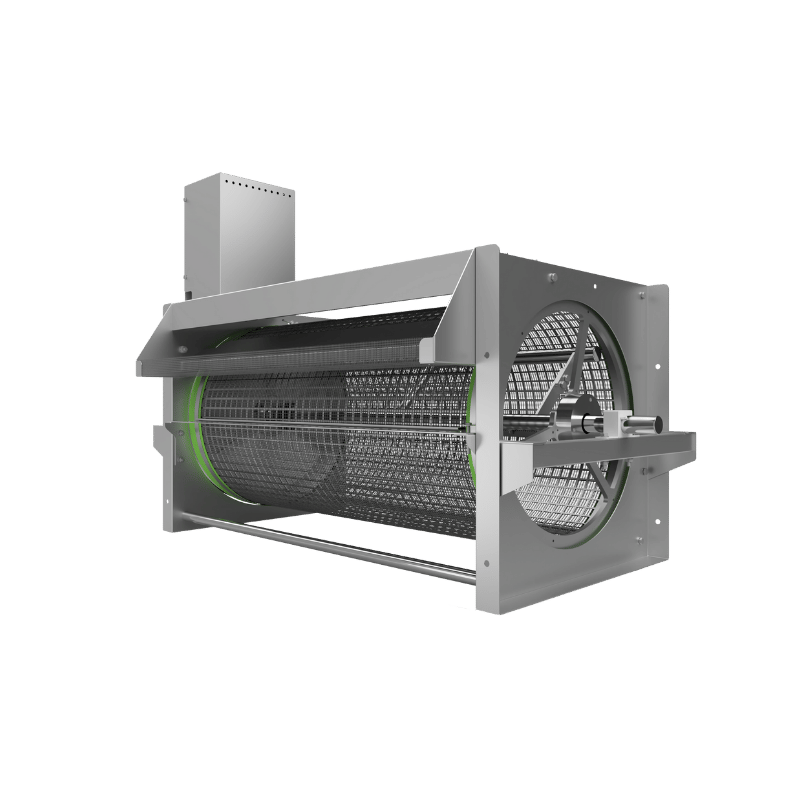

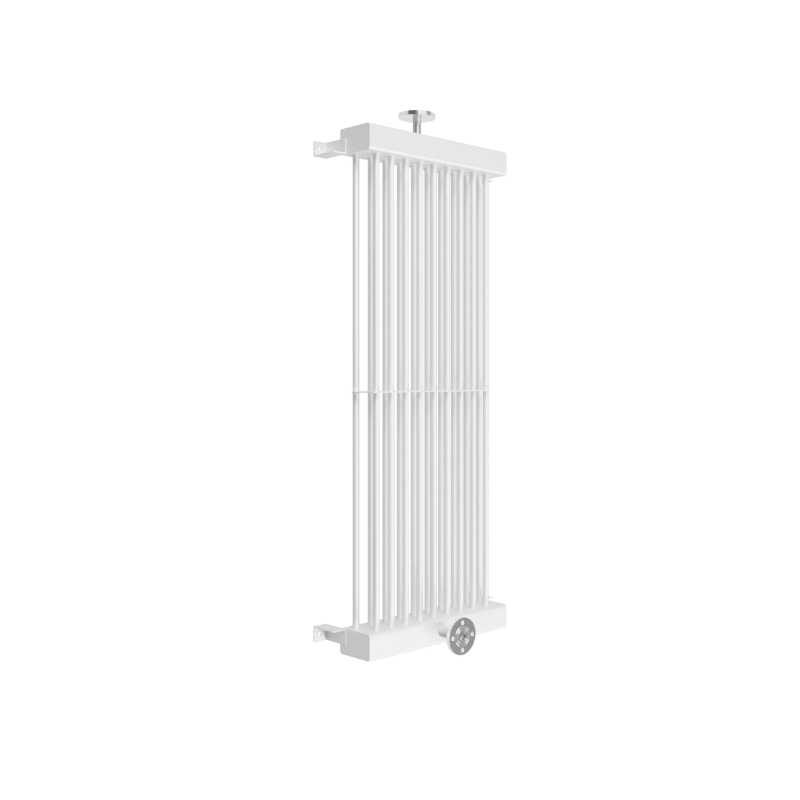

Filtration Components:

Air Conditioning Components:

Duct Design and Components

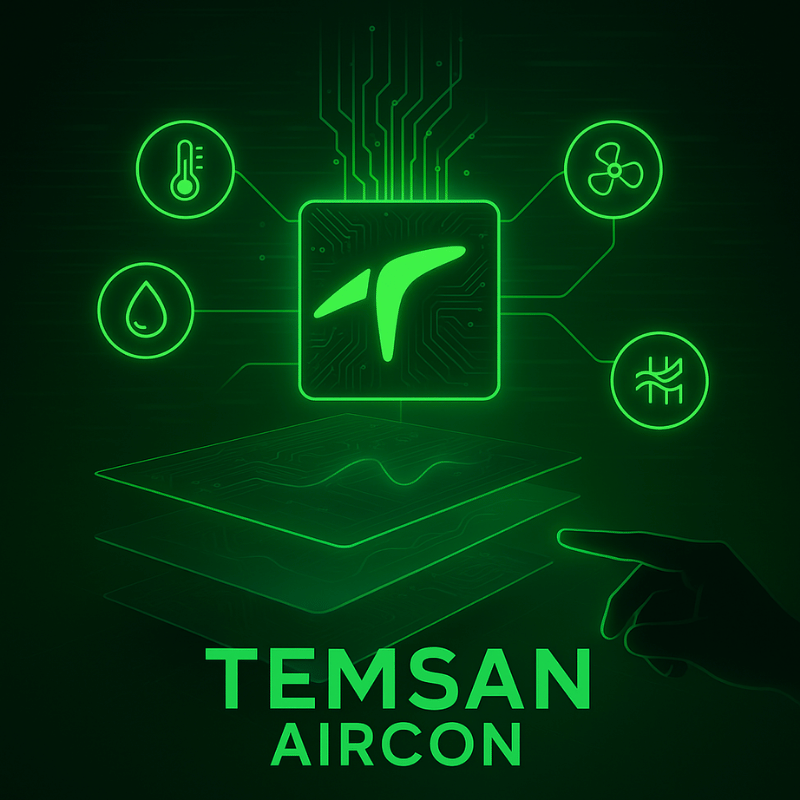

TEMSAN AIRCON

- Real-time monitoring of temperature, humidity, and airflow

- Inverter-controlled axial fans for energy-efficient air delivery

- Servo dampers automatically balance fresh, exhaust, and return air

- Mobile and web-based access through Temsan Aircon platform

- Automatic and manual operation via HMI and SCADA interface

- Chiller & heating compatability with easy management

- Designed to run energy efficient to reduce your cost with higher productivity

- Real-time tower zone monitoring

Key Considerations in Textile A/C and Filtration Systems

High-Quality Products

Energy Efficiency