SPINNING APPLICATIONS

Maintaining the highest yarn quality in spinning (ring) operations requires the right Temsan A/C and Filtration Systems. These systems control temperature and humidity, prevent disruptions in the production line, and enhance efficiency. The Temsan A/C System reduces operational costs and improves energy efficiency.

Optimizing Air Conditioning for Spinning Efficiency

Maintaining proper humidity, temperature, air quality, and energy balance is essential in spinning halls. Below, you’ll find how each of these factors contributes to better yarn quality, lower costs, and higher machine efficiency.

Maintaining optimal humidity is essential for yarn quality, machine performance, and a stable environment.

- Prevents Yarn Breakage: Keeps fibers flexible and reduces breakage during processing.

- Minimizes Static Electricity: Prevents fiber clinging and processing disruptions.

- Reduces Fiber Fly and Dust: Maintains a cleaner working environment.

- Improves Yarn Strength & Uniformity: Ensures fiber cohesion and consistency.

- Enhances Machine Performance: Prevents fiber buildup in machinery.

- Optimizes Energy Efficiency: Stabilizes indoor environment and reduces load on equipment.

Result: Higher productivity, reduced waste, and better yarn quality.

Precise temperature control ensures fiber stability, operator comfort, and machine reliability.

- Prevents Fiber Dryness & Breakage.

- Controls Moisture Balance: Avoids over-drying or over-moisturizing fibers.

- Reduces Static Electricity.

- Enhances Machine Performance: Prevents overheating.

- Optimizes Energy Consumption.

- Improves Worker Comfort & Productivity.

Result: Smoother operations, higher yarn quality, and energy savings.

Clean air is essential for minimizing contamination and protecting equipment and staff.

- Removes Fiber Fly and Dust.

- Prevents Yarn Contamination.

- Increases Machine Longevity.

- Improves Worker Health & Safety.

- Enhances Filtration Efficiency.

- Meets Industry Compliance Standards.

Result: Fewer downtimes, consistent quality, and better workplace health.

Efficient systems lower operational costs and support sustainable textile manufacturing.

- Reduces Power Consumption with inverter-controlled fans and motors.

- Optimizes Airflow Management.

- Enhances Machine Efficiency.

- Uses Smart Automation for Real-Time Adjustments.

- Minimizes Maintenance Costs.

- Supports Sustainability Goals and Carbon Reduction.

Result: More sustainable operations with lower long-term energy costs.

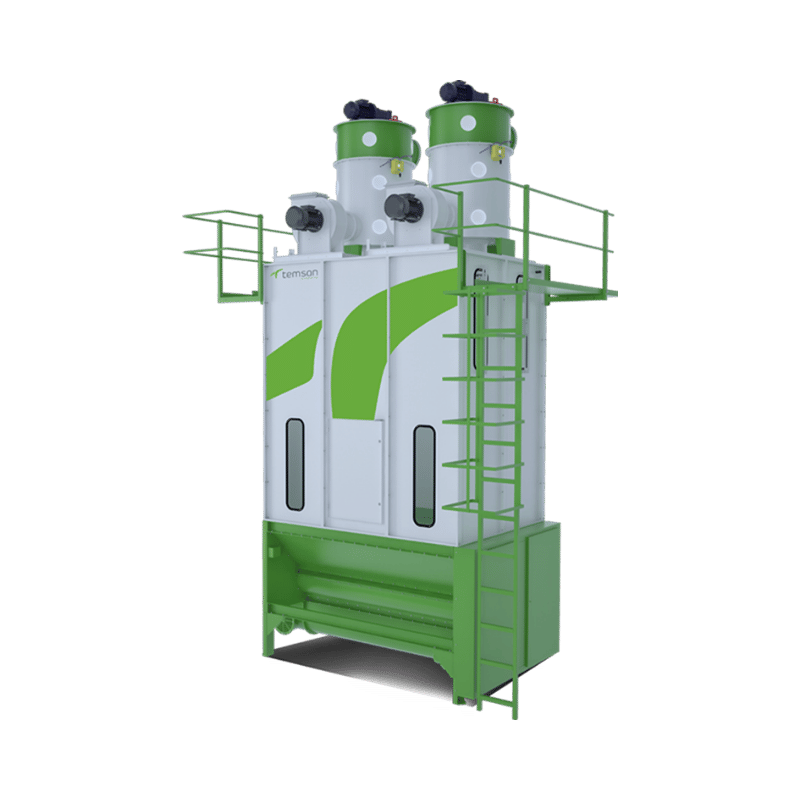

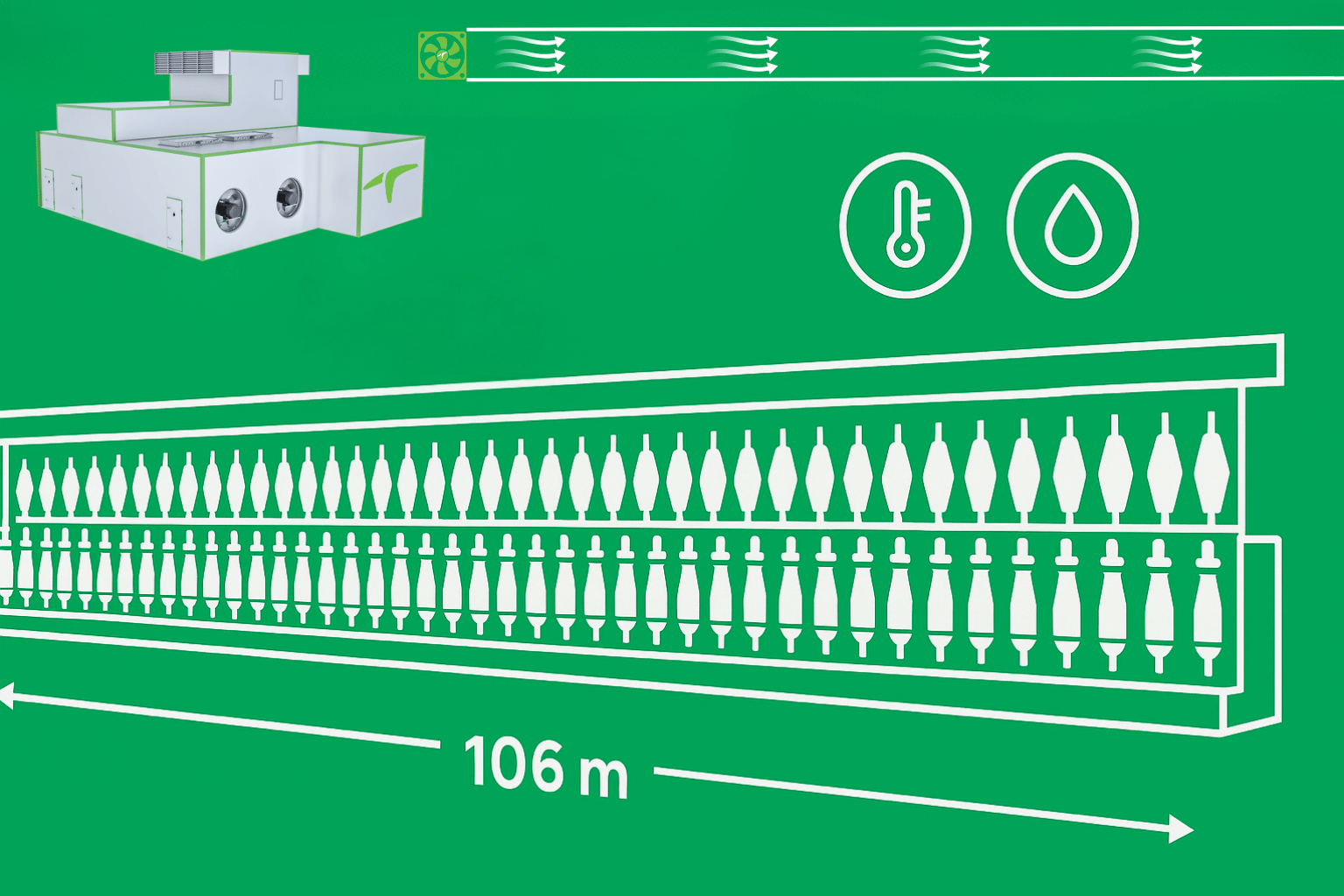

Unmatched Climate Control for One of the World’s Largest Mills

Spanning an impressive 106 meters, Temsan’s advanced air conditioning system is engineered to maintain optimal climate conditions across one of the world’s largest textile mills. From the service bay to the end of the mill, our cutting-edge technology ensures uniform temperature, humidity, and air quality—maximizing efficiency and productivity.

- 🔹 Precision Climate Control

- 🔹 Energy-Efficient Operation

- 🔹 Seamless Automation with Aircon

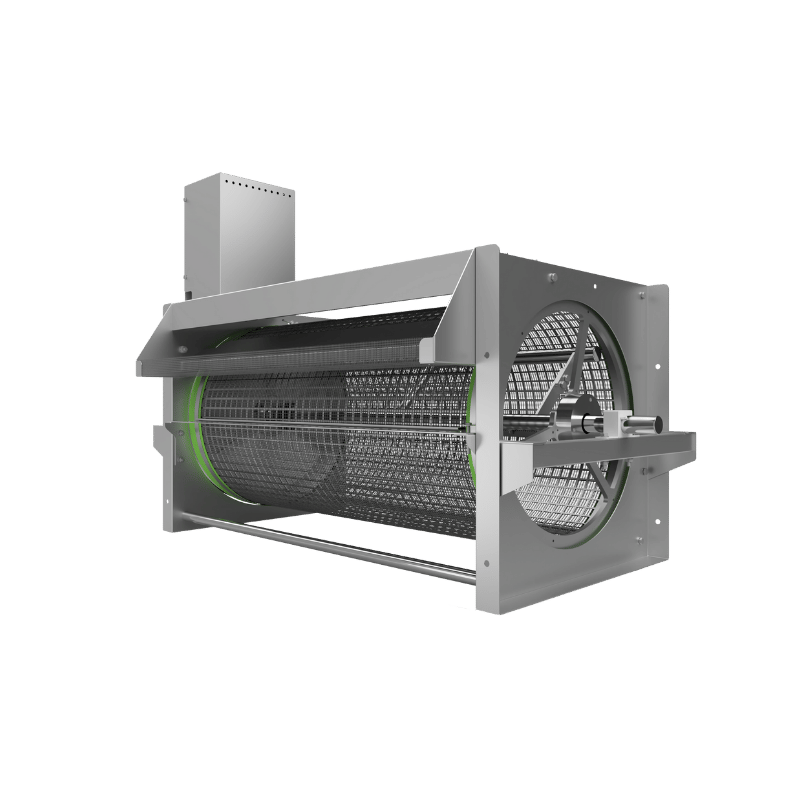

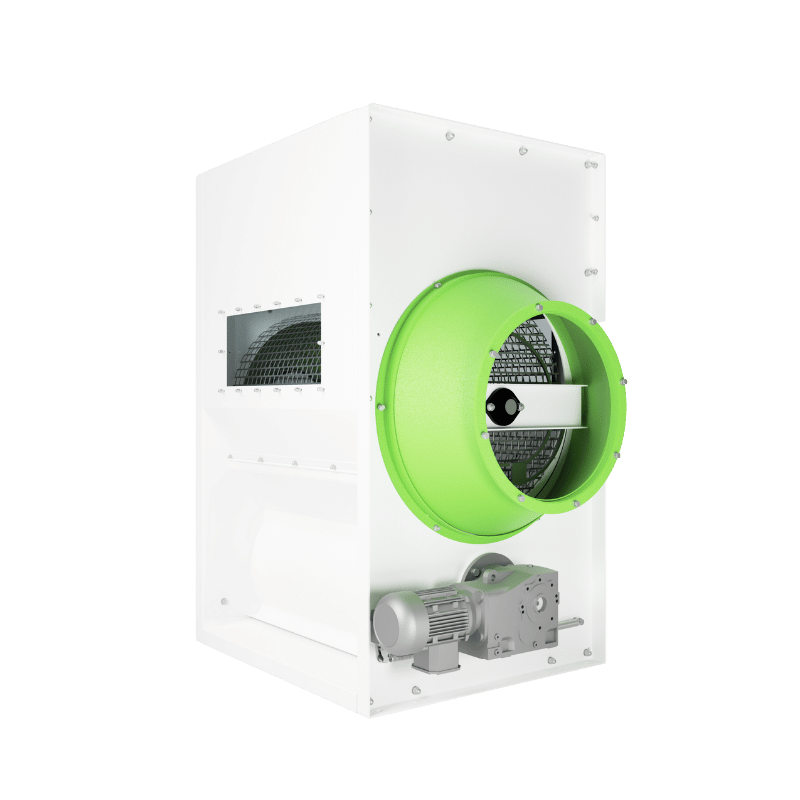

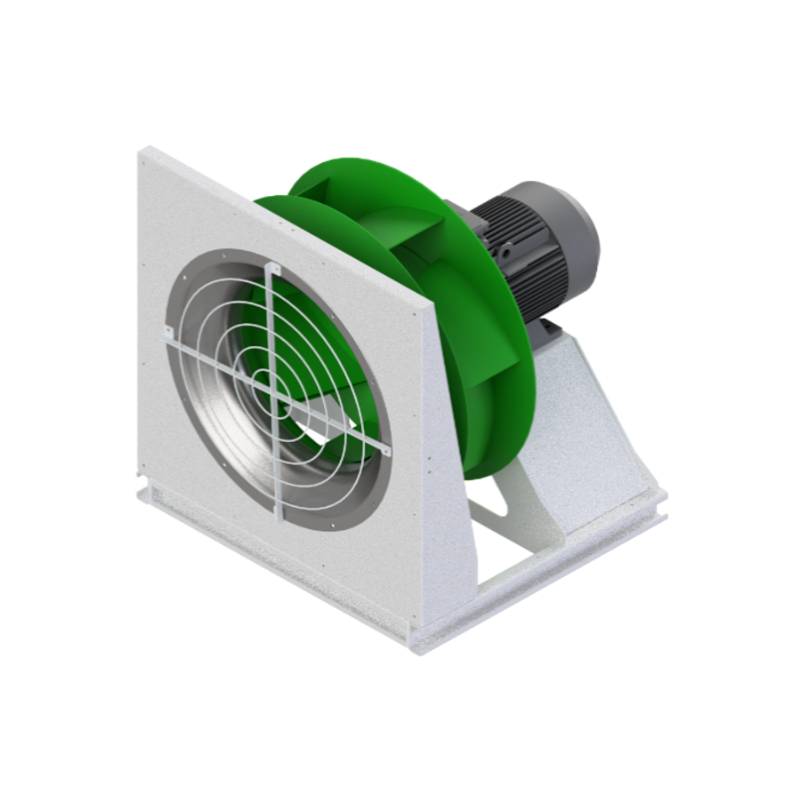

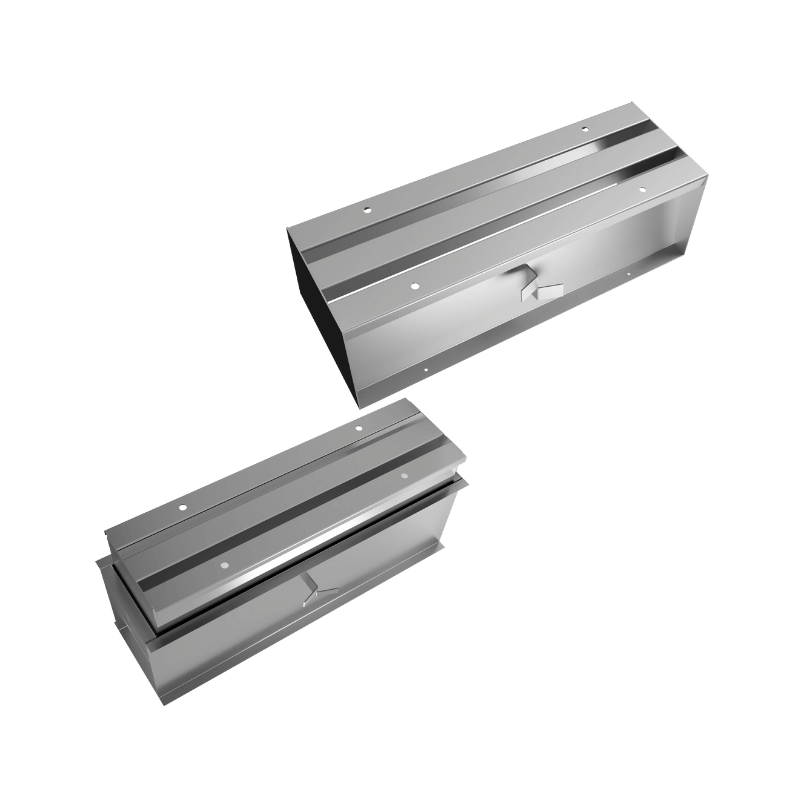

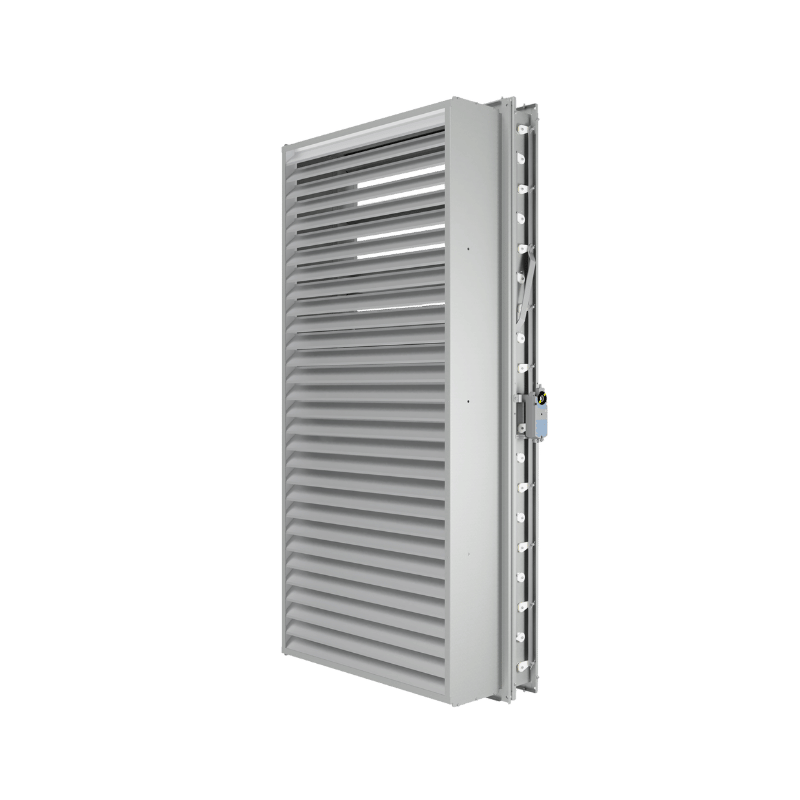

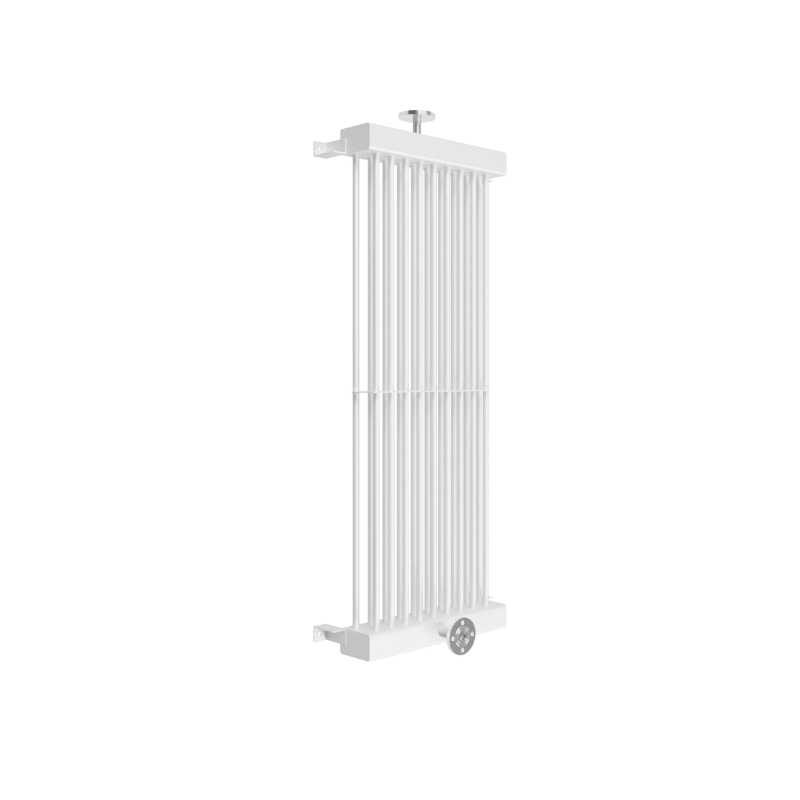

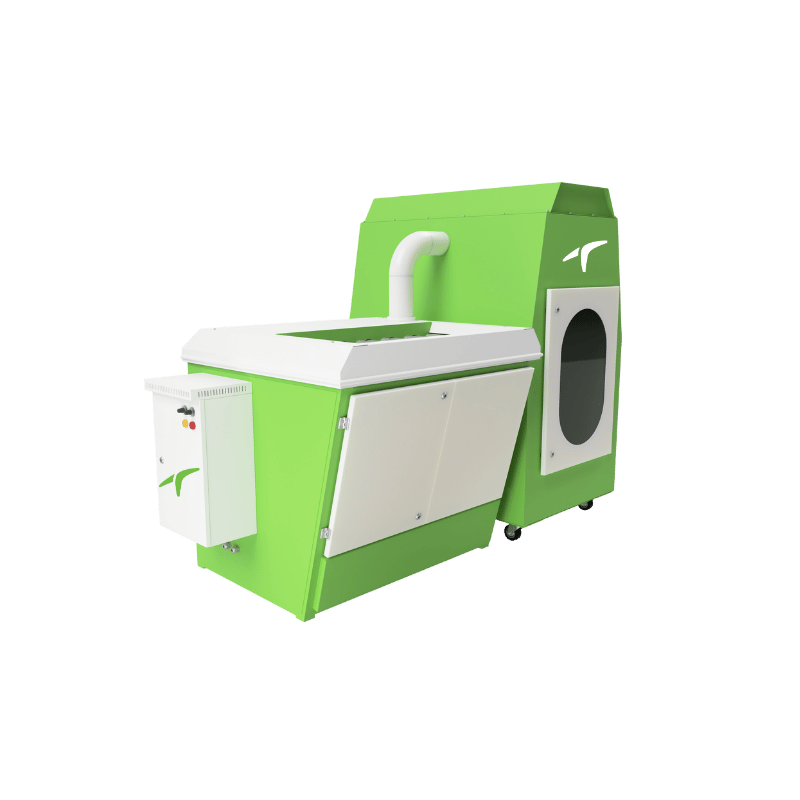

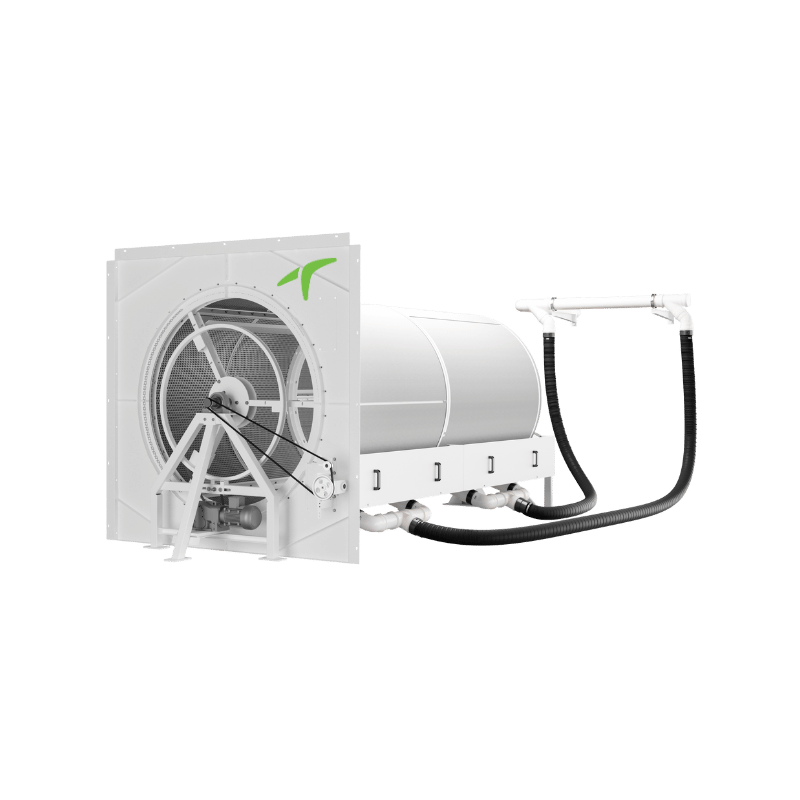

Key Components of Temsan Air Conditioning and Filtration Systems

Filtration Components:

Air Conditioning Components:

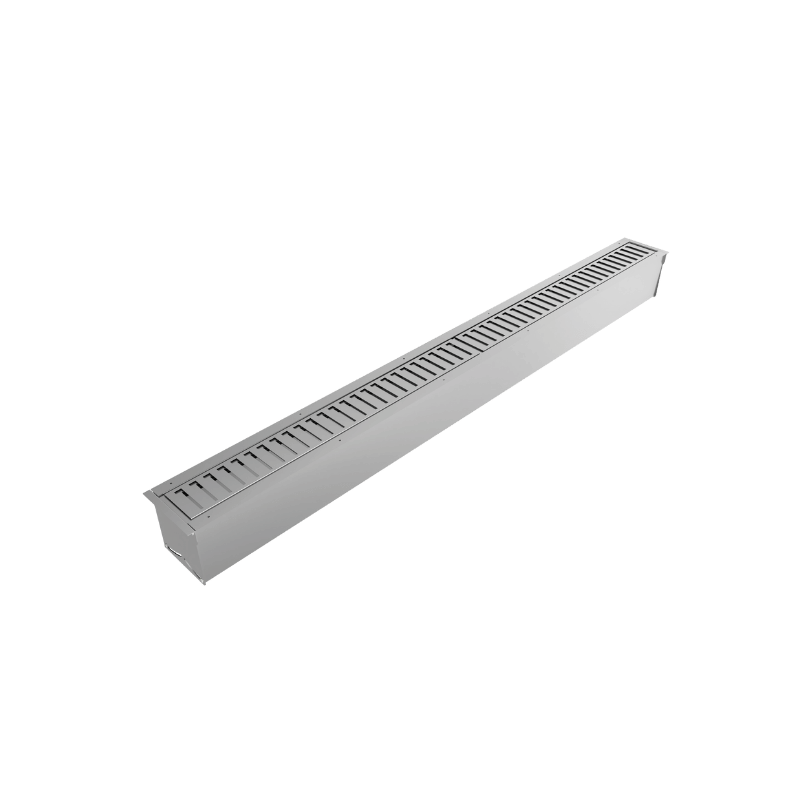

Duct Design and Components

Integrated Waste & Dust Management for Spinning

Waste Management Automation

Dust Management Automation

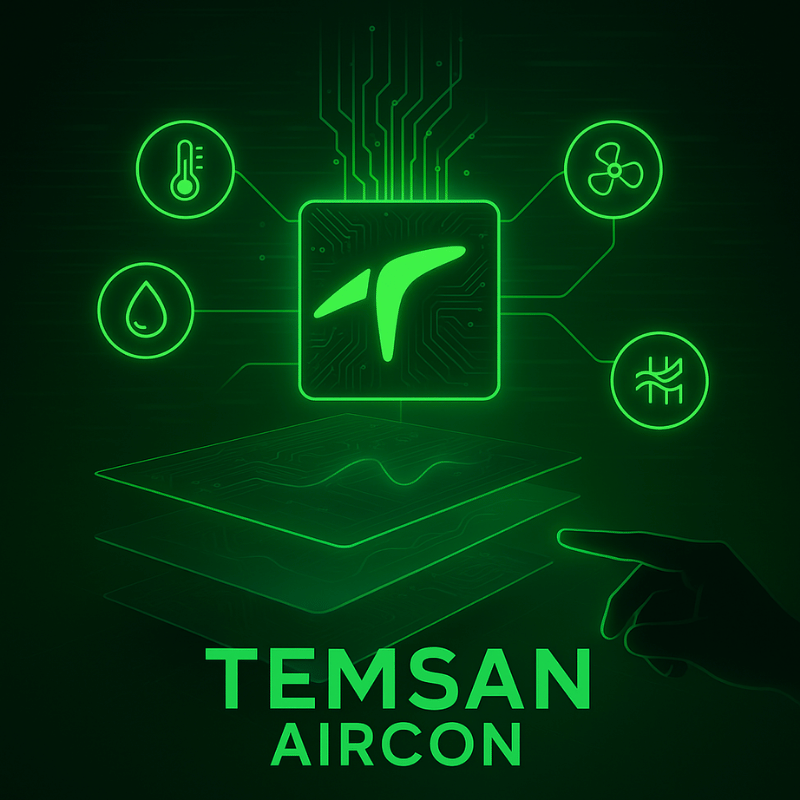

TEMSAN AIRCON

- Real-time monitoring of temperature, humidity, and airflow

- Inverter-controlled axial fans for energy-efficient air delivery

- Servo dampers automatically balance fresh, exhaust, and return air

- Mobile and web-based access through Temsan Aircon platform

- Automatic and manual operation via HMI and SCADA interface

- Chiller & heating compatability with easy management

- Designed to run energy efficient to reduce your cost with higher productivity

Key Considerations in Textile A/C and Filtration Systems

High-Quality Products

Energy Efficiency

Low Maintenance Costs

This post is also available in:

Türkçe (Turkish)