TWISTING & DOUBLING APPLICATIONS

In twisting and doubling operations, stable air conditions are critical to yarn alignment, ballooning control, and energy efficiency. Temsan provides tailored air conditioning and filtration systems that maintain optimal environmental balance — reducing tension variability, preventing contamination, and ensuring smooth winding processes.

Precision Climate Control for Twisting Stability

Maintaining proper humidity, temperature, air quality, and energy balance is essential in twisting and doubling halls. These parameters directly impact yarn integrity, tension uniformity, and the lifespan of twisting and winding components. Below, you’ll find how each factor contributes to higher product quality, smoother machine operation, and reduced energy consumption.

Controlled humidity helps prevent fiber separation, fly generation, and static issues in twisting processes.

- Prevents Balloon Friction and Yarn Breaks

- Reduces Static Between Yarn Ends

- Supports Uniform Twisting Tension

- Decreases Airborne Waste Generation

Result: Consistent twist quality and reduced cleaning needs.

Even air temperature across the production area ensures equipment stability and prevents heat-related yarn distortion.

- Reduces Bearing and Motor Overheating

- Protects Yarn Strength from Thermal Stress

- Ensures Stable Yarn Ballooning

- Improves Operator Comfort

Result: Fewer machine stoppages and lower rejection rates.

Clean air is essential for minimizing yarn contamination and preventing fly accumulation on sensors and yarn paths.

- Prevents Yarn Guide Obstruction

- Keeps Winding Heads Free from Dust

- Extends Maintenance Intervals

- Supports Accurate Yarn Path Tracking

Result: Reduced downtime, better yarn package build, and improved cleanliness.

- Removes Fiber Fly and Dust.

- Prevents Yarn Contamination.

- Increases Machine Longevity.

- Improves Worker Health & Safety.

- Enhances Filtration Efficiency.

- Meets Industry Compliance Standards.

Result: Fewer downtimes, consistent quality, and better workplace health.

Temsan’s inverter-controlled systems and low-pressure ducting design ensure energy-smart operation in twisting halls.

- Fan Speed Adapts Based on Machine Heat Load

- Reduced Airflow Resistance Saves Power

- Automation Tracks Climate Demand in Real Time

- Lower Static Pressure Ensures Cost-Efficient Operation

Result: Lower electricity bills and stable production conditions.

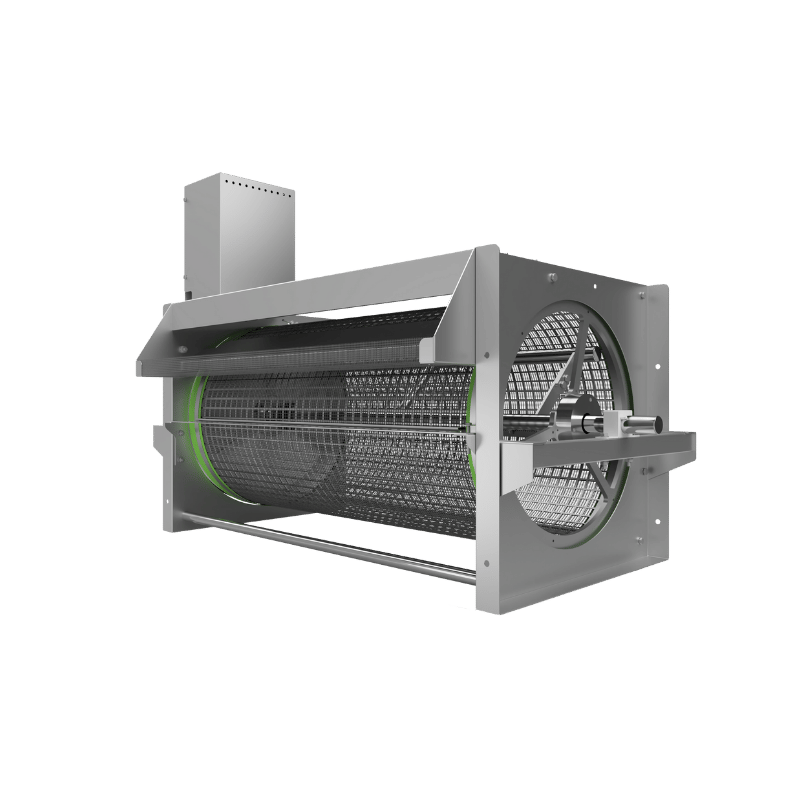

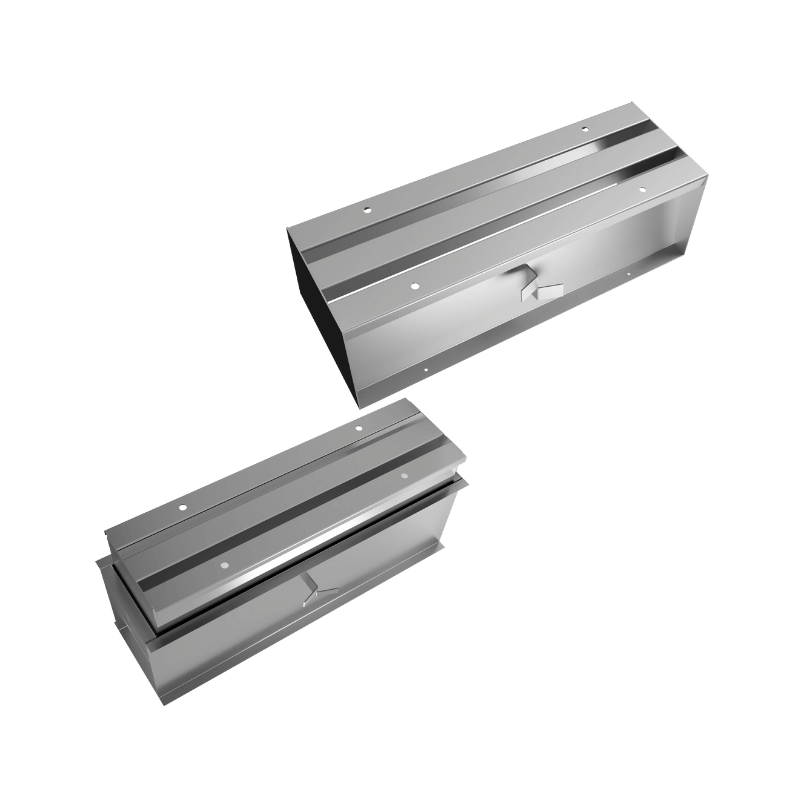

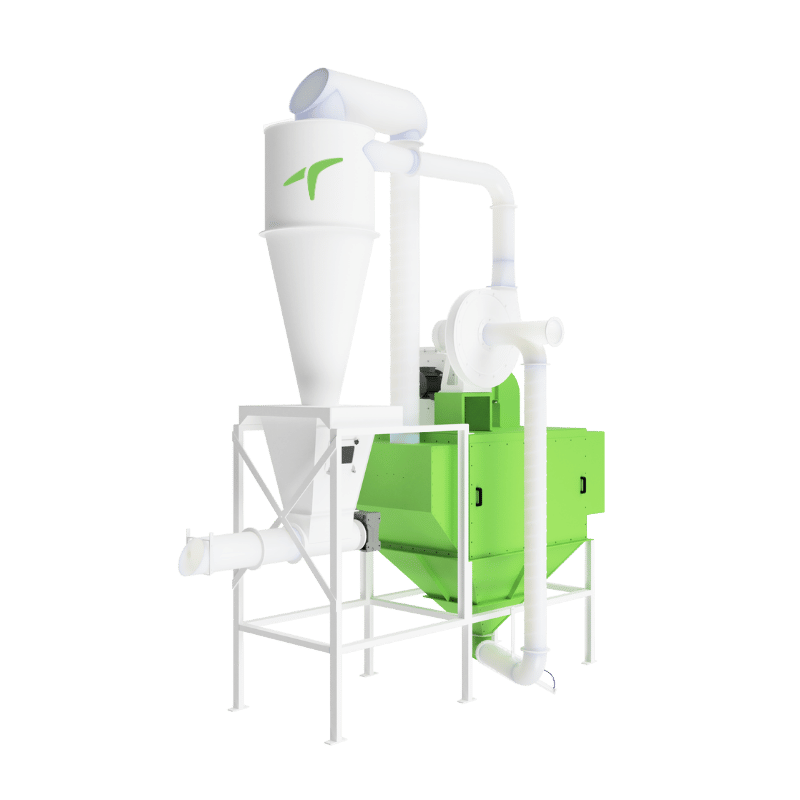

Exhaust Separation System

Developed by Temsan – Proven Since 2007

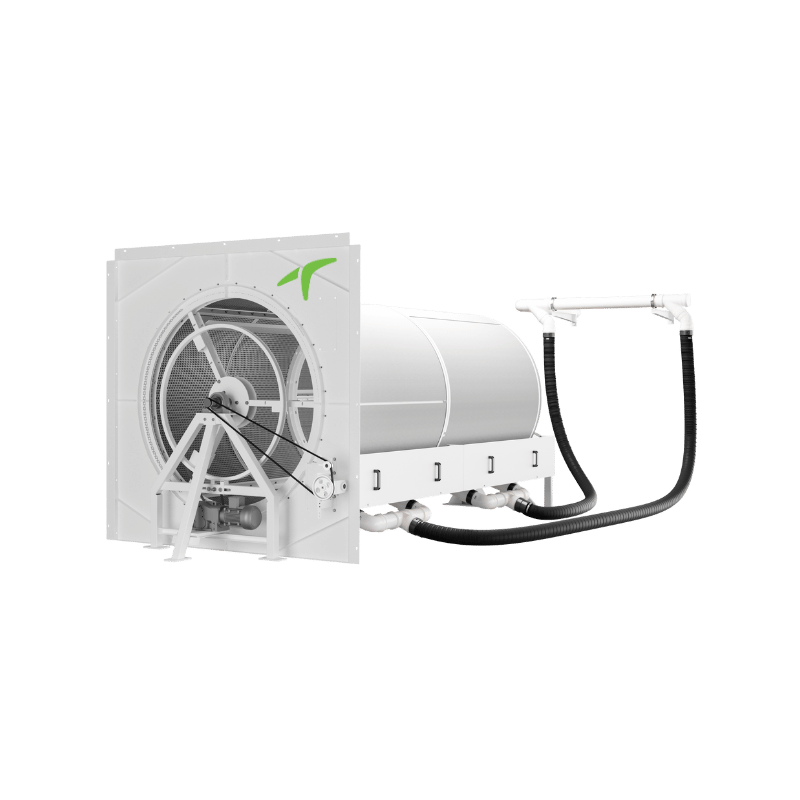

Temsan’s proprietary Exhaust Separation System is designed specifically for Open-End spinning operations. It filters the hot exhaust air directly from the machines before it interacts with the hall’s return airflow.

Once filtered through the Rotary Filter, Temsan Aircon Automation intelligently determines whether the air should be:

- 🌬️ Exhausted to outdoors through exhaust dampers

- ♻️ Reused by mixing with hall return air in front of the Air Washer

This smart routing prevents heat accumulation, enhances air quality, and boosts energy efficiency across the system.

- ✅ Filters machine exhaust at source

- ✅ Dynamic exhaust or reuse decision

- ✅ Fully automated via Aircon system

- ✅ Enhances energy and climate performance

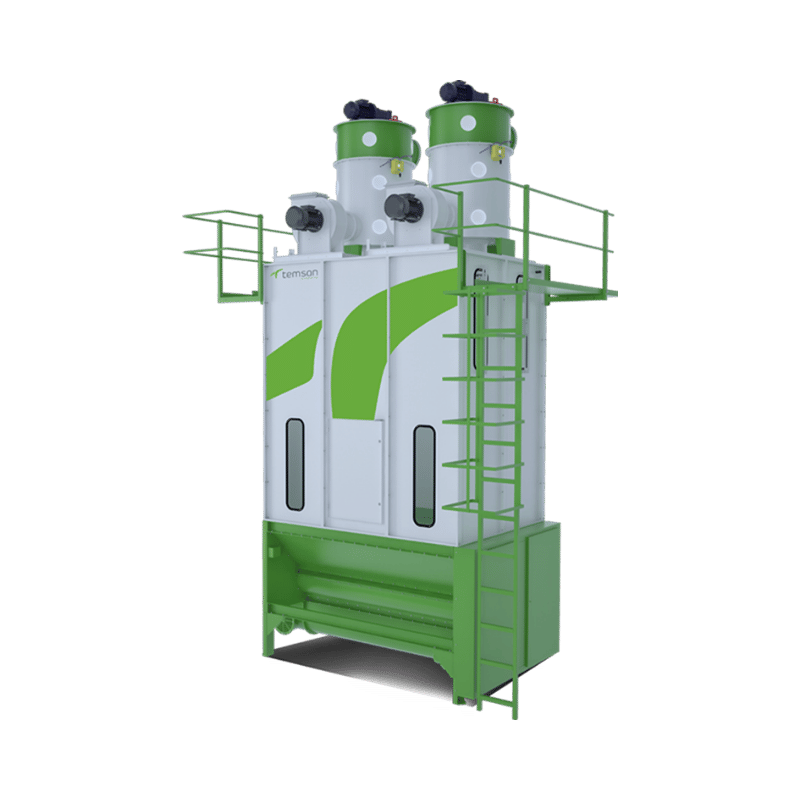

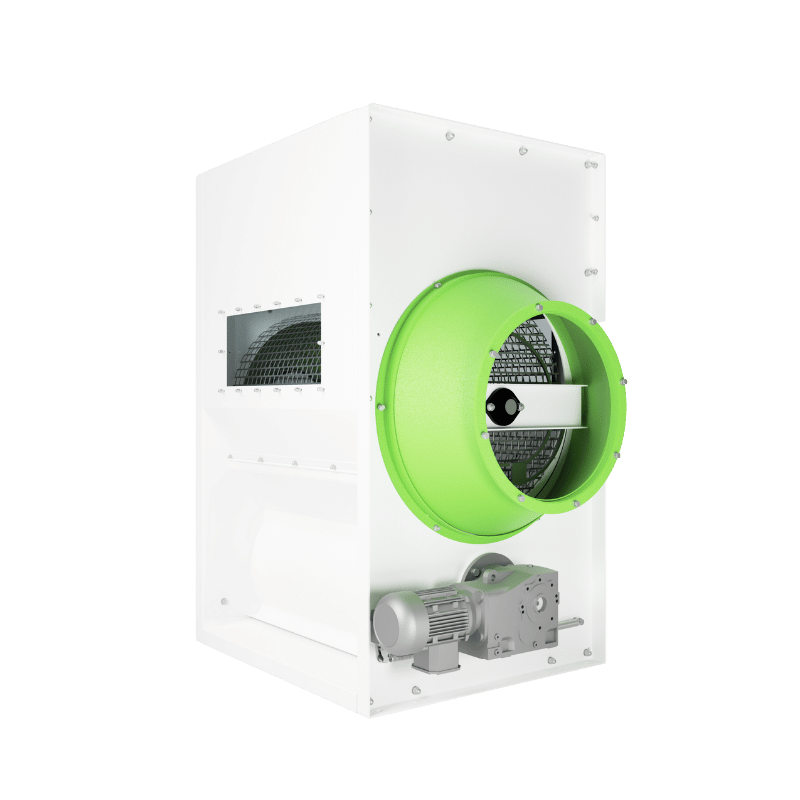

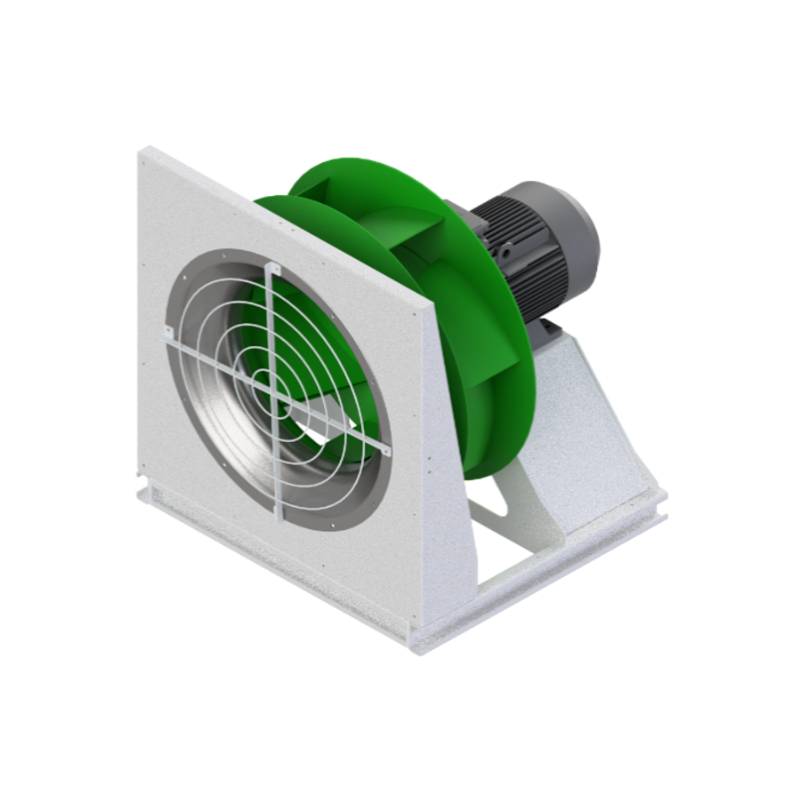

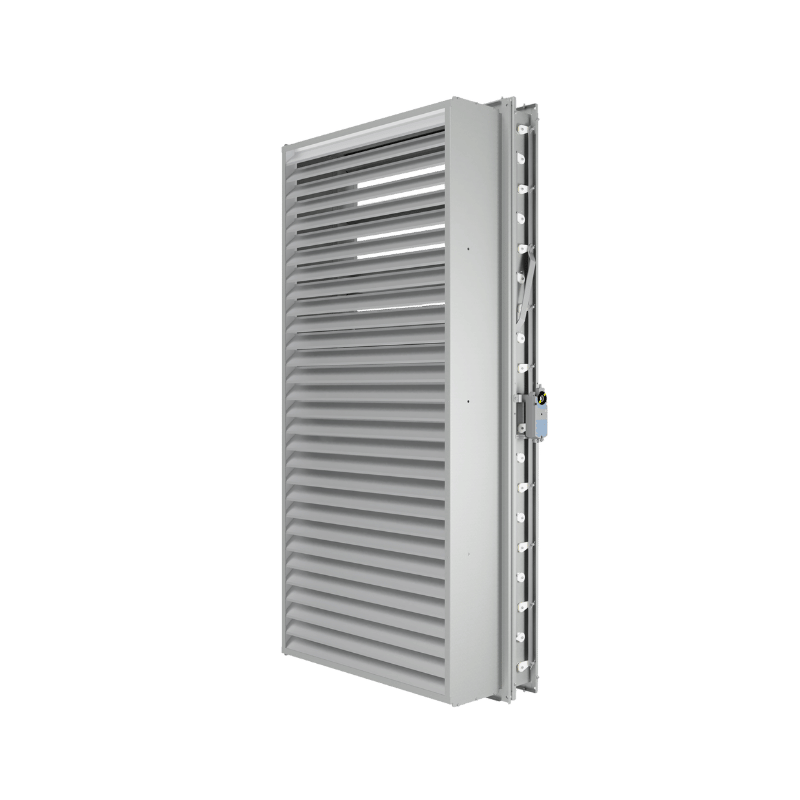

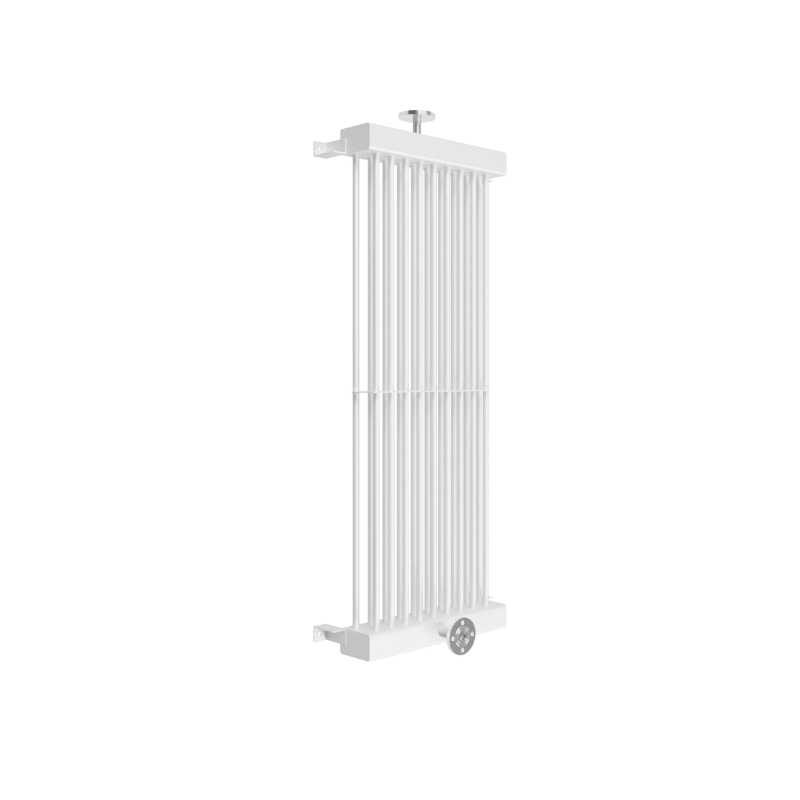

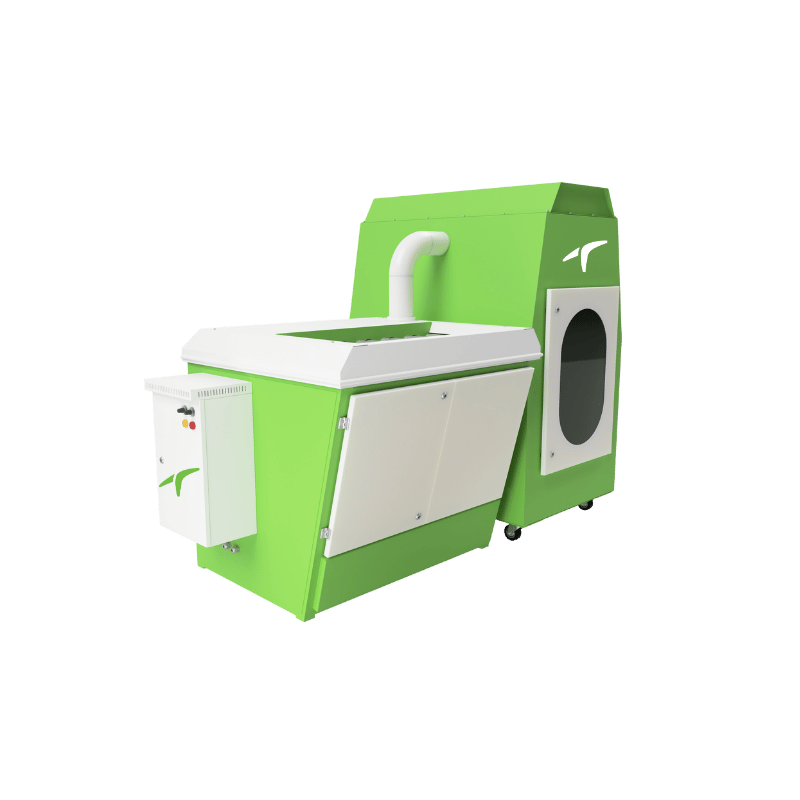

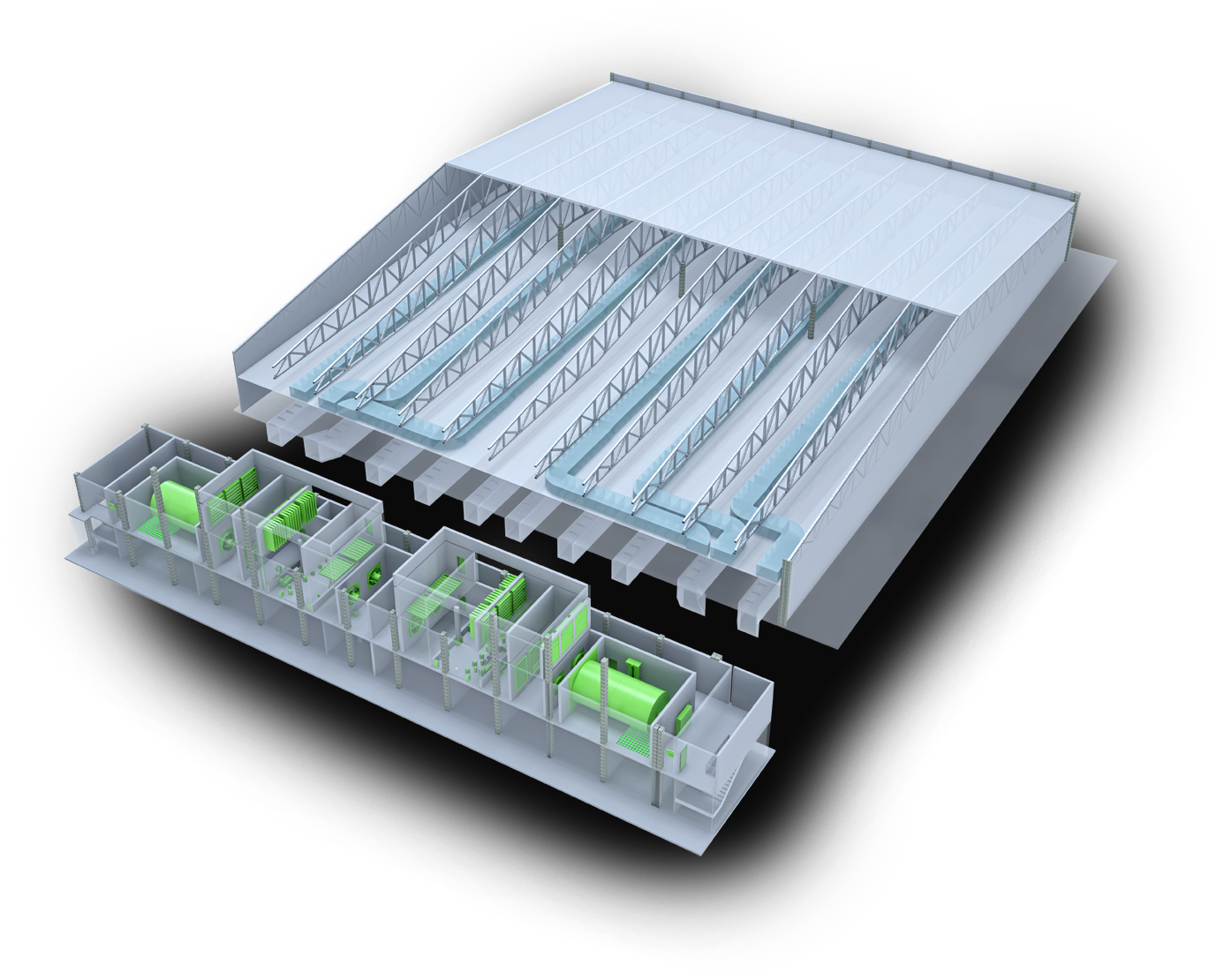

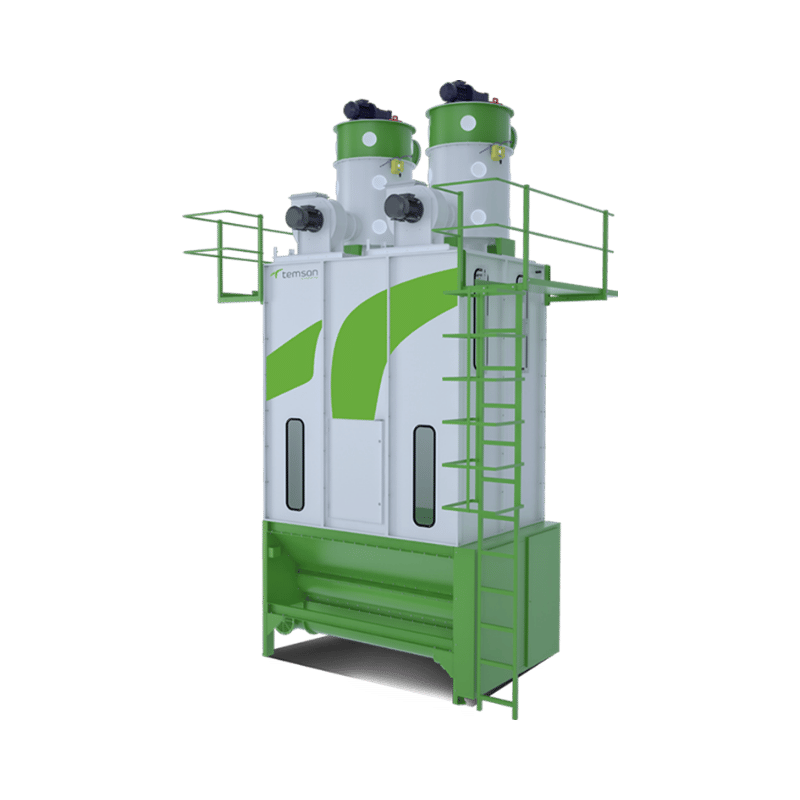

Key Components of Temsan Air Conditioning and Filtration Systems

Filtration Components:

Air Conditioning Components:

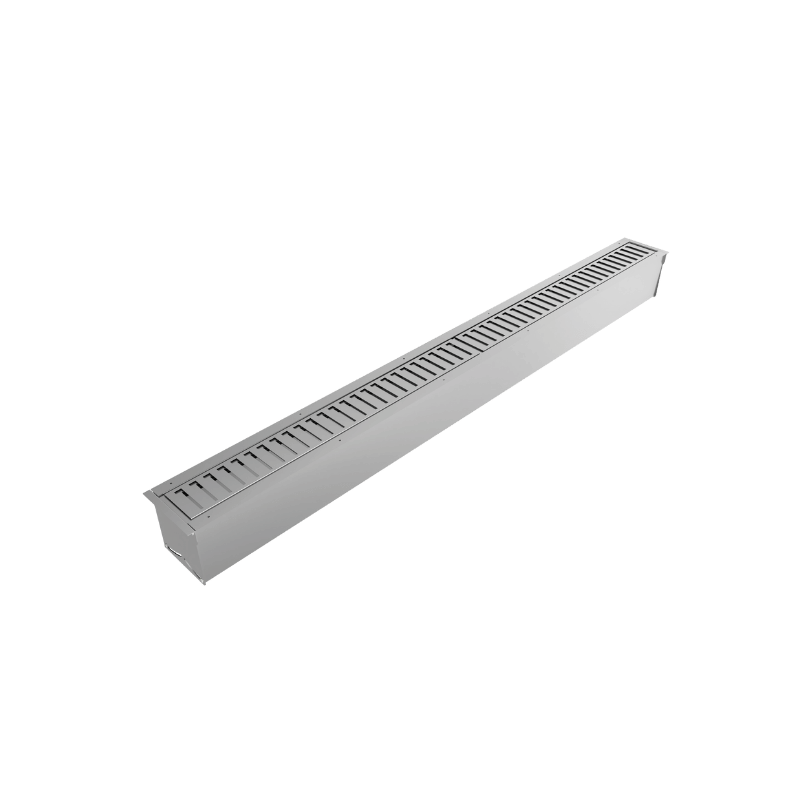

Duct Design and Components

Integrated Waste & Dust Management for Spinning

Waste Management Automation

Dust Management Automation

TEMSAN AIRCON

- Real-time monitoring of temperature, humidity, and airflow

- Inverter-controlled axial fans for energy-efficient air delivery

- Servo dampers automatically balance fresh, exhaust, and return air

- Mobile and web-based access through Temsan Aircon platform

- Automatic and manual operation via HMI and SCADA interface

- Chiller & heating compatability with easy management

- Designed to run energy efficient to reduce your cost with higher productivity

Key Considerations in Textile A/C and Filtration Systems

High-Quality Products

Energy Efficiency