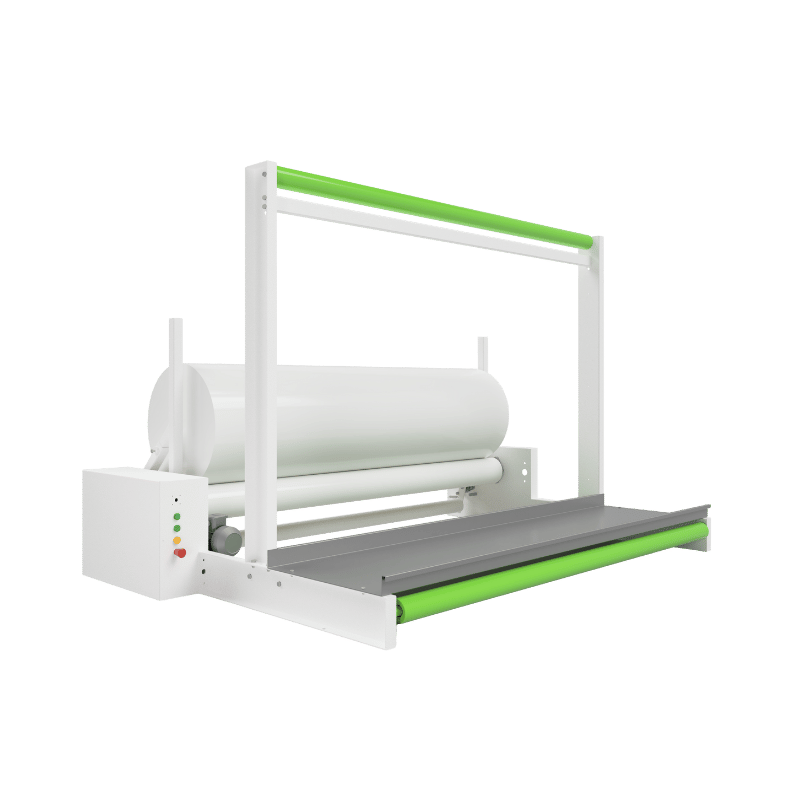

Batcher

This post is also available in:

Türkçe (Turkish)

Temsan Batcher machines are engineered to provide precise, smooth, and tension-controlled fabric rolling for weaving, denim, and lycra-blended textile applications.

Designed for high-performance weaving operations, the Batcher ensures uniform rolling without damaging the fabric structure — even at varying densities, tensions, and fabric types.

Thanks to its digitally adjustable working speed (0.1 m/min to 2.5 m/min), operators can easily synchronize the machine with the loom, ensuring seamless downstream handling.

The robust rubber-coated cylinders (Ø165 mm) provide excellent grip and abrasion resistance, supporting consistent rolling quality across long production cycles.

The integrated tension sensing arm continuously monitors fabric tension, automatically adjusting rolling speed through the electronic control system. This ensures perfect winding density, smooth fabric edges, and stable package formation.

Temsan Batchers are built with a durable steel frame, easy-access control panel, and reliable electronic components — making them ideal for demanding mills seeking long-term performance and minimal downtime.

Optional features such as inspection screens and automatic pneumatic discharge further enhance efficiency and operator convenience.

⚙️ Key Features

-

Adjustable Working Width: 1,900 mm – 3,800 mm

-

Rolling Diameter: Up to 1,500 mm

-

Electronic Speed Control: 0.1–2.5 m/min, fully synchronized with the loom

-

Fabric Compatibility: Denim, woven fabrics, lycra blends

-

Durable Rolling Cylinders: Ø165 mm, rubber-coated for abrasion resistance

-

Tension Synchronization: Real-time sensing arm for perfect winding density

-

User-Friendly Control Panel: Forward/reverse motion buttons and signal indicators

-

Strong Industrial Build: Designed for stability and long-term durability

-

Low Maintenance: Easy-access mechanical layout and reliable components

🧩 Optional Features

-

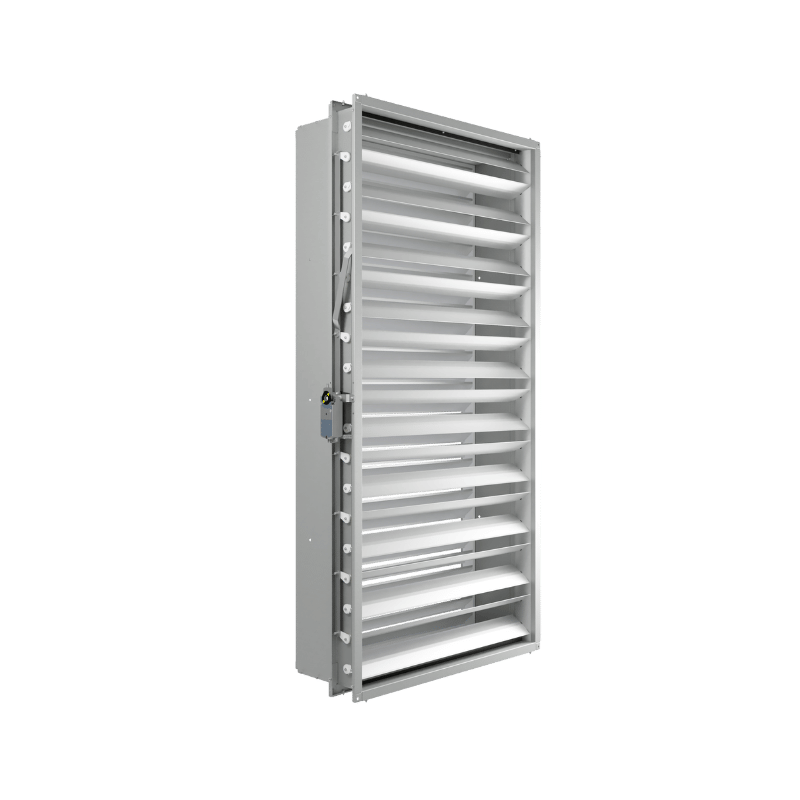

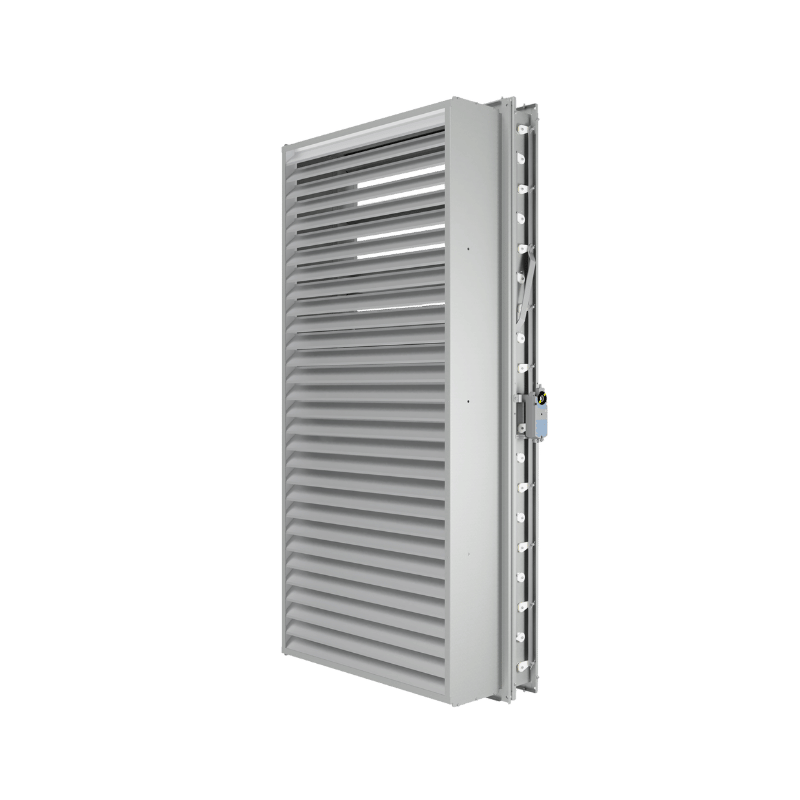

Inspection Screen: Vertical or bent design for fabric checking

-

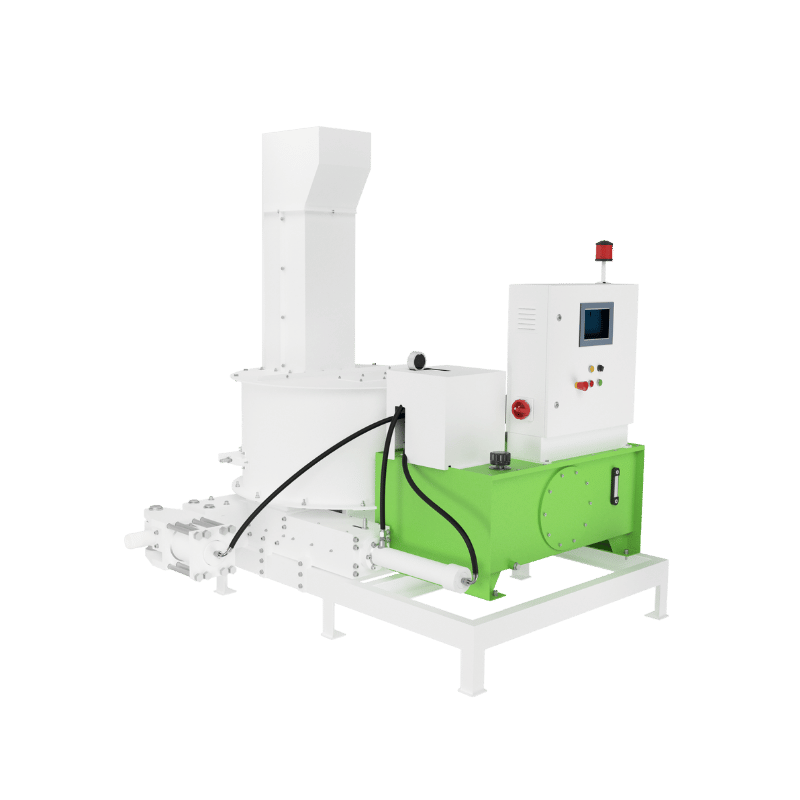

Automatic Discharge (Pneumatic): High-efficiency unloading

-

Manual Discharge: Cost-effective alternative

-

Custom Working Widths: Tailored for different loom sizes

🌍 Applications

Temsan Batcher is ideal for:

-

Denim Production – uniform rolling and tension control

-

High-Speed Weaving Lines – synchronized fabric handling

-

Quality-Control Zones – especially with inspection screen option

-

Lycra and Stretch Fabrics – smooth rolling without deformation

With its precision control, rugged construction, and smart synchronization, Temsan Batcher delivers reliable performance and superior fabric handling for weaving mills seeking efficiency, quality, and long-term durability.