Dust Collection

This post is also available in:

Türkçe (Turkish)

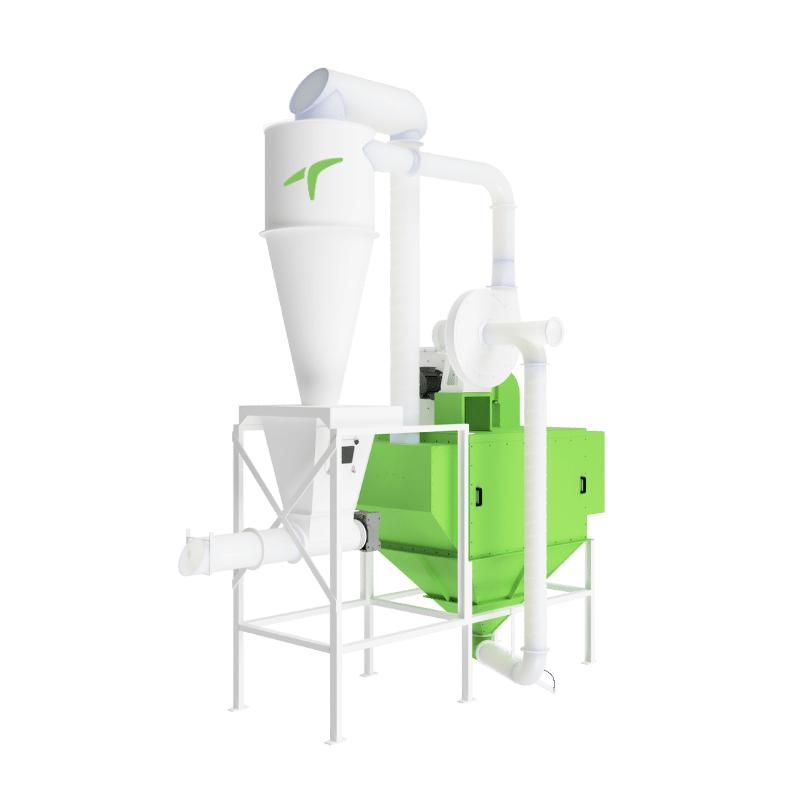

Temsan’s Automatic Dust Collection System is engineered for high-efficiency dust extraction, separation, and transfer in modern textile production environments.

Instead of traditional dust bags, the system uses sealed metal dust reservoirs, providing a cleaner, safer, and more hygienic solution for continuous dust management.

Dust collected from rotary filters or perpendicular filters is discharged into these metal reservoirs. From here, specially designed clamps at the outlet feed the dust into cyclones via round transfer pipes.

Inside the cyclone, airflow rotation separates fibres and dust through centrifugal force creating a highly efficient pre-separation process.

The system operates with intermittent suction, managed by Temsan’s automation logic.

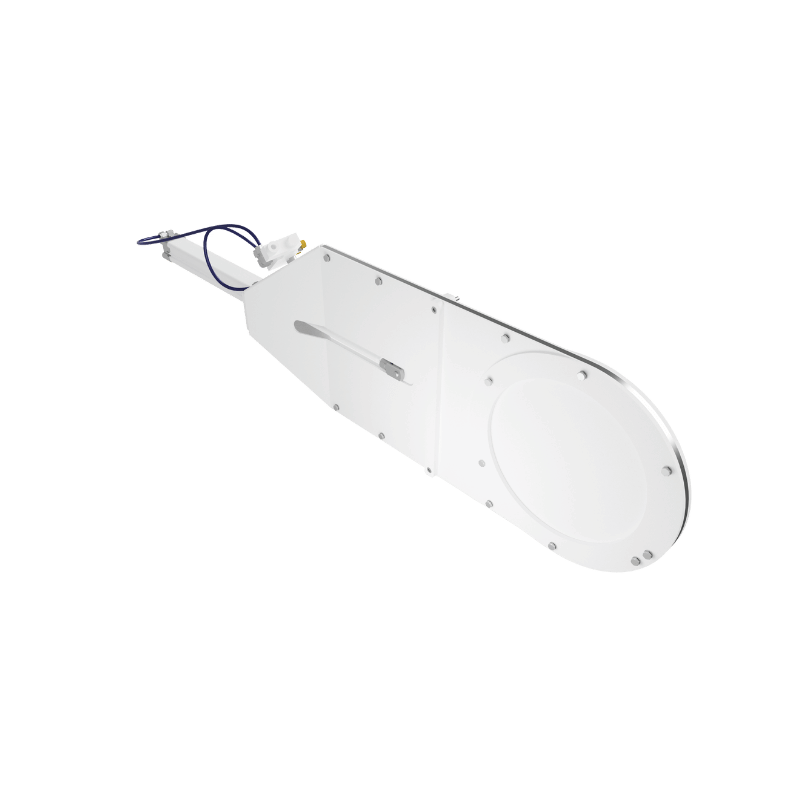

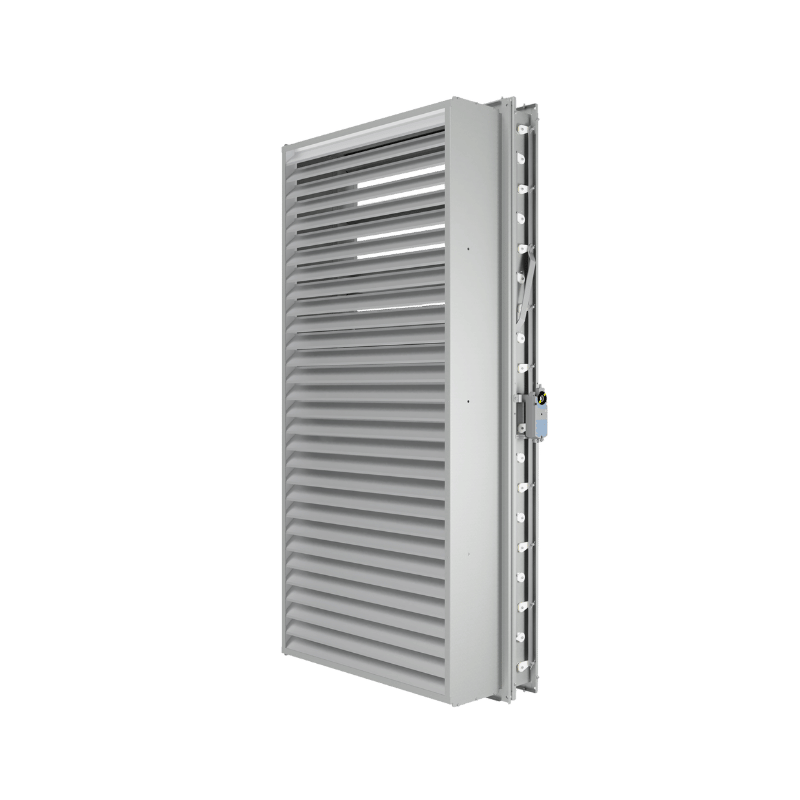

Pneumatic or servo sliders automatically open and close to regulate dust discharge frequency, ensuring stable system pressure and optimal suction at all times.

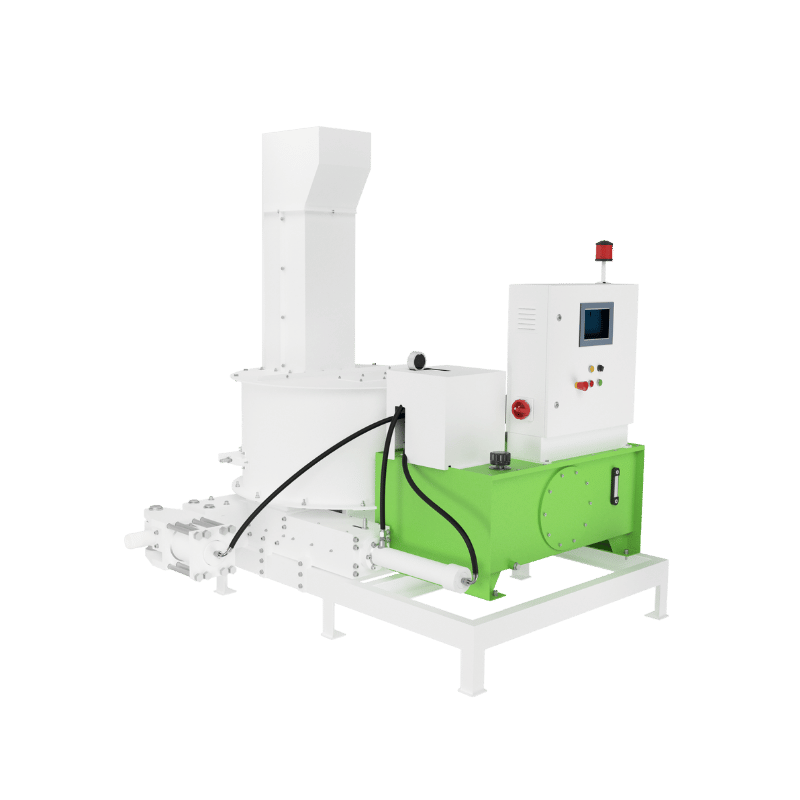

Once dust is separated and collected, it is transferred to the discharge point, where it enters a screw compression unit driven by an industrial gearbox.

This mechanism compresses dust and fibres, reducing their volume and preparing them for further handling — such as feeding into Temsan Dust Brick Machine or centralized dust rooms.

⚙️ Key Features

-

Cyclone-Based Separation: High-efficiency fibre and dust separation using centrifugal force.

-

Intermittent Suction Operation: Automation-driven slider valves regulate on/off suction timing.

-

Metal Dust Reservoirs: Hygienic, durable containers replacing traditional dust bags.

-

Clamped Dust Transfer: Dust exits via clamp-controlled outlets into round transfer piping.

-

Screw Compression Unit: Dust and fibres are compacted using gearbox-driven screw motion.

-

Stable Pressure Control: Automation ensures constant suction and system stability.

-

Energy-Efficient Design: Optimized airflow paths minimize fan load and power consumption.

-

Fully Integrated: Works seamlessly with rotary filters, paddle boxes, dust fans, and cyclones.

🌍 Applications

Ideal for:

-

Rotary Filter Dust Handling

-

Perpendicular Filter Discharge

-

Centralized Dust Rooms

-

Nonwoven Dust Extraction

-

Spinning & Open-End Lines

-

Dust Brick or Compression Systems

Temsan’s cyclone-equipped intermittent dust collection solution delivers cleaner production floors, reduced labour, and continuous dust extraction performance essential for energy-efficient and safe textile manufacturing.