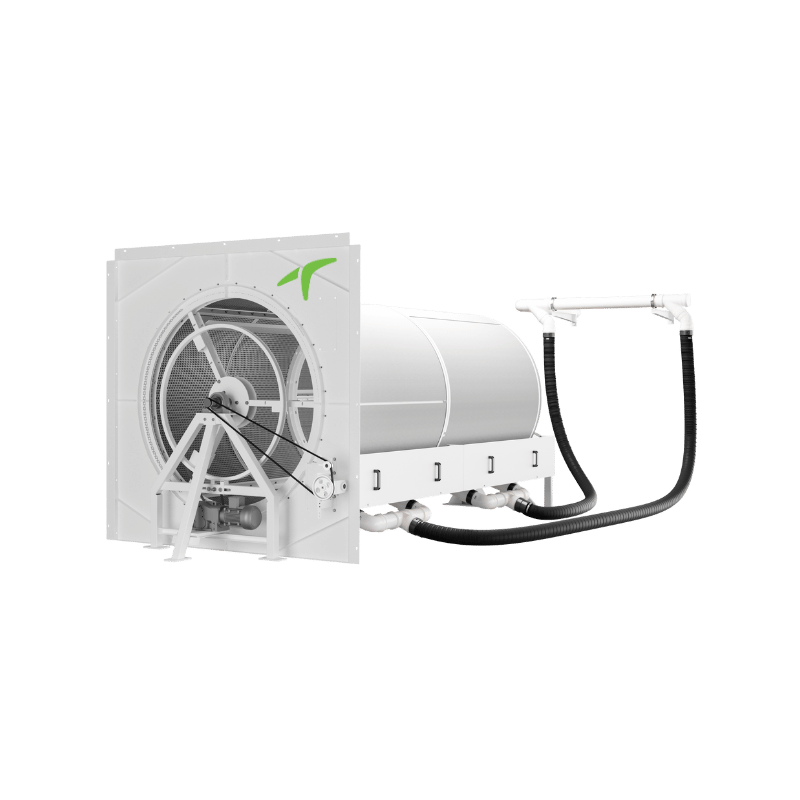

Rotary Filter

Temsan Rotary Filters are engineered to deliver high-capacity dust and fibre filtration for textile production environments, maintaining clean hall conditions and stable system performance.

Working as the primary fine-filtration unit, the rotary filter captures airborne impurities from halls, production machines, and duct systems — ensuring a cleaner, safer, and more efficient operation.

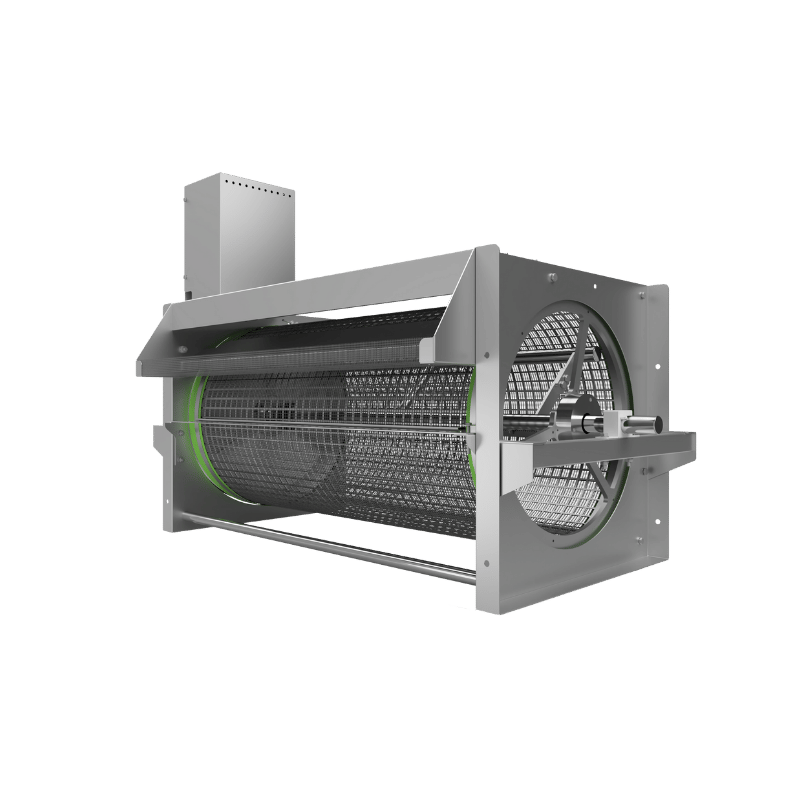

Available in diameters of 2000 mm, 2500 mm, 3000 mm, and 3500 mm with multiple length options (170 cm, 340 cm, 510 cm, 680 cm), Temsan Rotary Filters can be sized precisely according to the airflow requirements of spinning, open-end, weaving, and nonwoven applications.

The filter body is coated with electrostatic powder paint, providing excellent corrosion resistance, long-term durability, and clean surface aesthetics.

The filtration surface is covered with 8 mm acrylic filter media (360–460 g/m²) designed for high dust-holding capacity and easy-clean performance, minimizing maintenance needs and maximizing filtration efficiency.

A specially engineered double-section nozzle system ensures strong, even surface cleaning during suction cycles while maintaining low room pressure, optimizing system energy consumption and overall filtration effectiveness.

⚙️ Key Features

-

Multiple Size Options: Diameters of 2000 / 2500 / 3000 / 3500 mm and lengths of 170 / 340 / 510 / 680 cm

-

High-Performance Filtration: Captures fine dust and fibres from halls and machines

-

Durable Construction: Electrostatic powder-coated body ensures long-lasting use

-

Easy-Clean Filter Media: 8 mm acrylic, 360–460 gr/m² high-quality cover

-

Double-Section Nozzle Design: Provides efficient filter surface cleaning and stable system pressure

-

Low Maintenance Needs: Engineered for long filter life and reduced downtime

-

Energy-Efficient Operation: Optimized airflow design reduces pressure loss and fan load

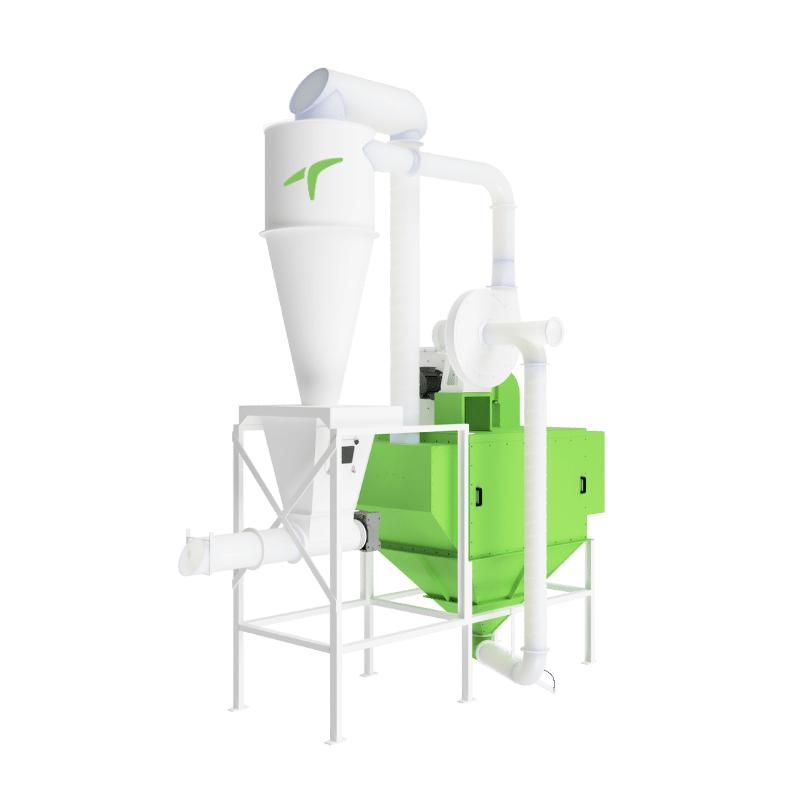

🌍 Applications

Temsan Rotary Filters are ideal for:

-

Spinning (Ring) Mills – removing airborne lint and microdust

-

Open-End Units – ensuring clean rotor environments

-

Weaving Halls – minimizing fly and improving air quality

-

Nonwoven Production – controlling dust load before finishing

-

Filtration Rooms – central dust collection and distribution

By combining uniform surface cleaning, robust construction, and high-efficiency filtration, Temsan Rotary Filters help textile mills maintain clean production halls, lower maintenance costs, and achieve more stable climate and filtration performance.